Sure, here is a list of frequently asked questions (FAQ) with answers for sourcing a filling and capping machine from SourcifyChina factory:

Q1: What types of filling and capping machines are available at SourcifyChina?

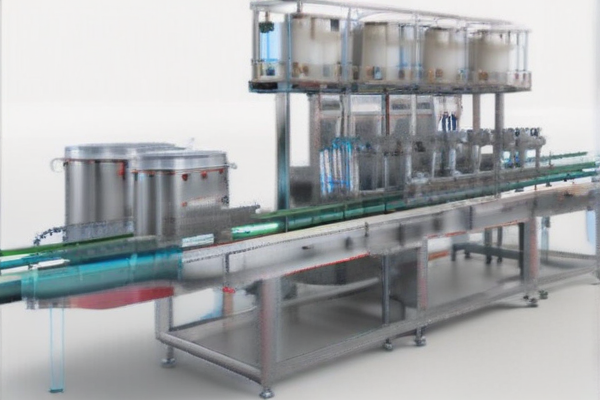

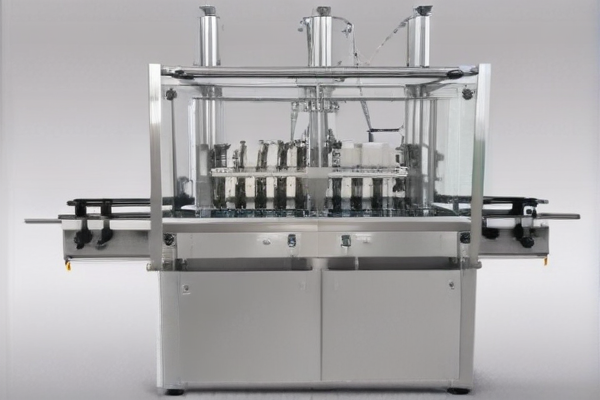

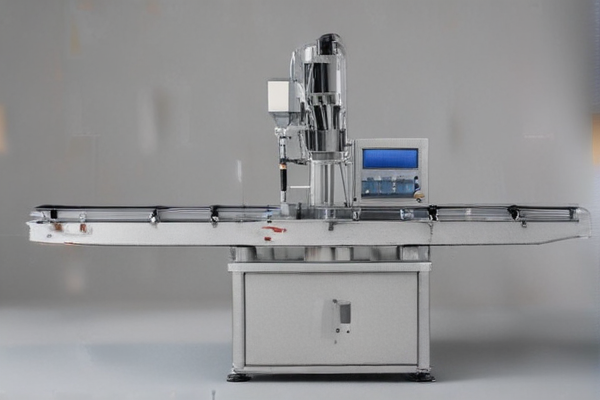

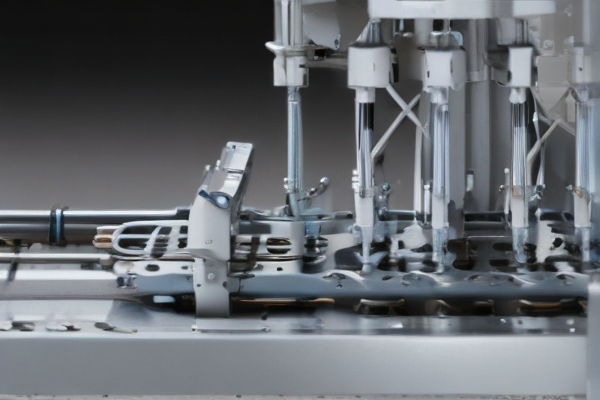

A1: SourcifyChina offers a variety of filling and capping machines including liquid filling machines, paste filling machines, and automatic capping machines. They cater to industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals.

Q2: How can I place an order for a filling and capping machine?

A2: To place an order, visit the SourcifyChina website and browse the product listings. You can contact their sales team directly via email or phone to discuss your specific needs, request a quote, and finalize your purchase.

Q3: What is the lead time for delivering filling and capping machines?

A3: The lead time typically ranges from 4-8 weeks, depending on the complexity of the machine and the level of customization required. SourcifyChina provides an estimated delivery timeline upon order confirmation.

Q4: Do you offer customization for filling and capping machines?

A4: Yes, SourcifyChina offers customization to meet specific requirements, including alterations in machine size, capacity, material, and additional features. Contact their technical team to discuss your needs.

Q5: What kind of after-sales support does SourcifyChina provide?

A5: SourcifyChina provides comprehensive after-sales support including installation guidance, operator training, maintenance advice, and technical support. They also offer spare parts and service contracts.

Q6: What are the payment terms for purchasing from SourcifyChina?

A6: Payment terms typically include a 30% deposit upon order confirmation and the remaining 70% before shipment. They accept various payment methods including bank transfer, PayPal, and credit cards.

Q7: Are there any warranties available for the machines?

A7: Yes, SourcifyChina provides a standard one-year warranty covering parts and labor. Extended warranties and service plans can also be negotiated.

Q8: Can I request a demo or visit the factory?

A8: Yes, SourcifyChina welcomes potential customers to visit their factory for a demo. Virtual demos can also be arranged via video conferencing.

Q9: How does SourcifyChina ensure the quality of their machines?