Sure, here are some frequently asked questions (FAQ) along with their answers for manufacturing “filling and sealing machine quality work from SourcifyChina factory”:

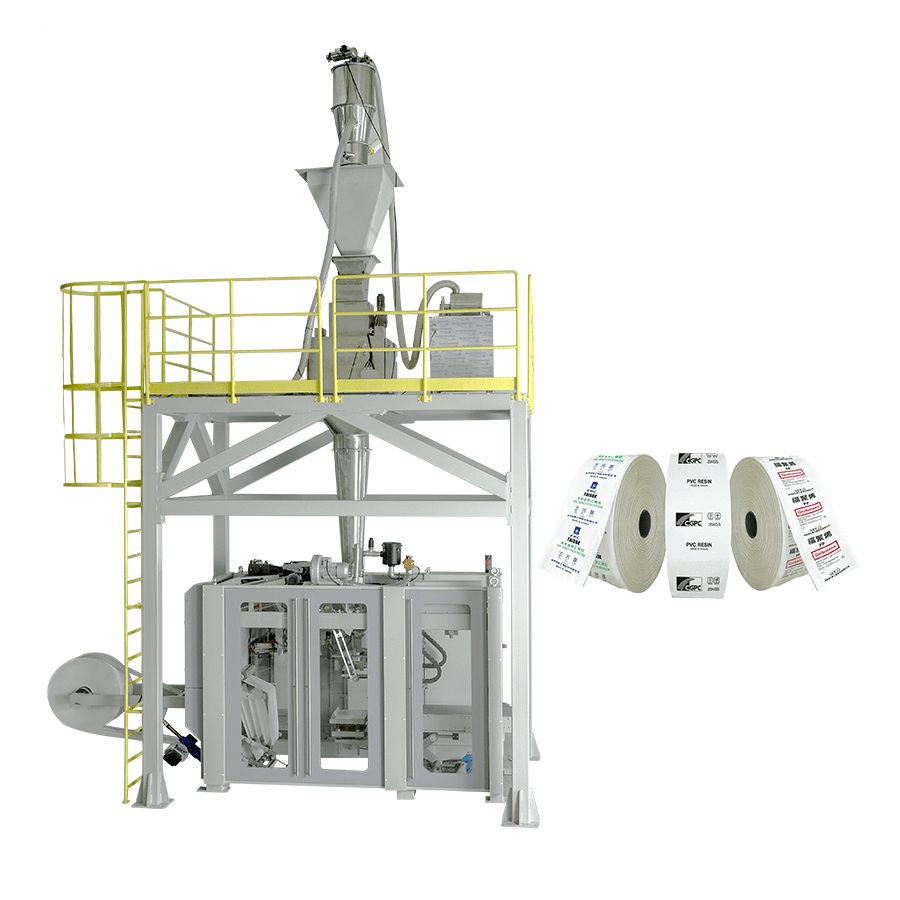

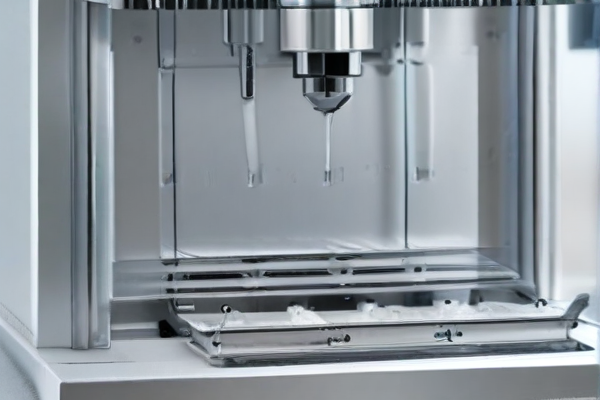

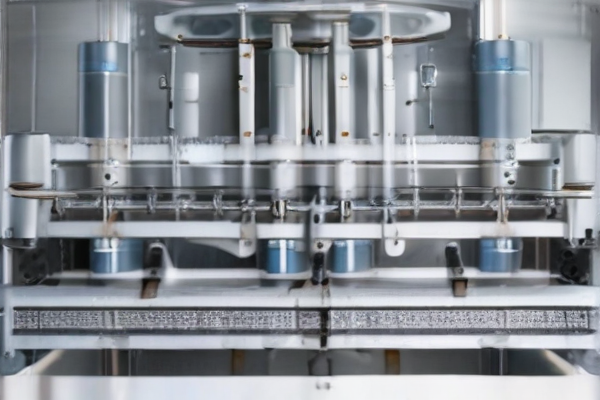

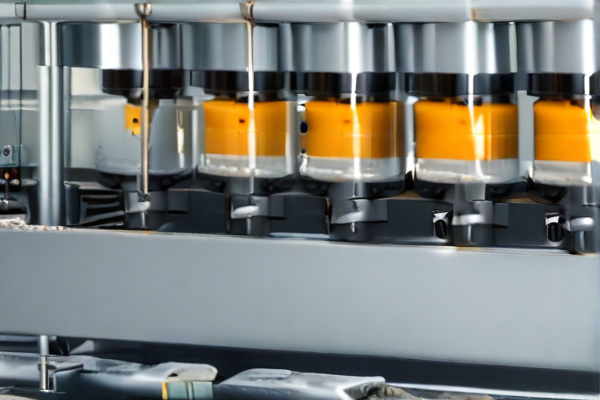

1. What types of filling and sealing machines does SourcifyChina factory offer?

SourcifyChina factory offers a wide range of filling and sealing machines, including liquid fillers, paste fillers, granule fillers, and powder fillers. These machines are suitable for various industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals.

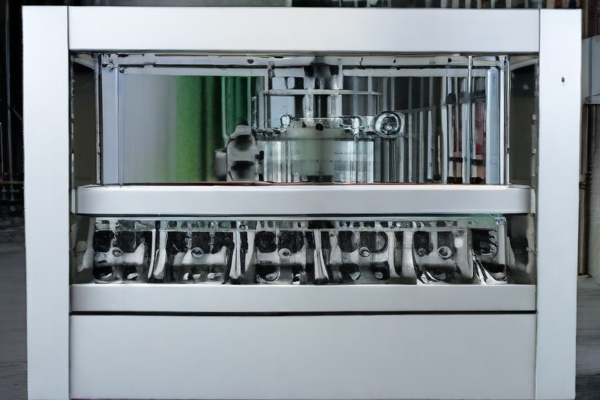

2. What quality standards do the machines from SourcifyChina factory adhere to?

SourcifyChina factory ensures that all their machines comply with international quality standards such as ISO, CE, and GMP. Each machine undergoes rigorous testing and quality checks to guarantee reliability and performance.

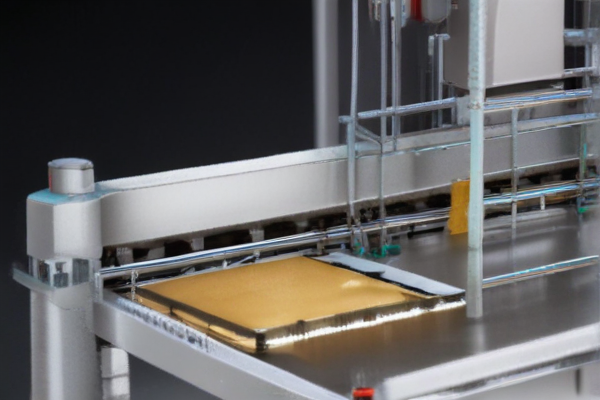

3. Can the machines be customized to fit specific production needs?

Yes, SourcifyChina factory offers customization options for their filling and sealing machines. They can customize the machine based on your specific requirements, including filling capacity, speed, and the type of materials used in construction.

4. What kind of after-sales support does SourcifyChina factory provide?

SourcifyChina factory provides comprehensive after-sales support, including installation assistance, training for your staff, regular maintenance services, and readily available spare parts. Their customer service team is always on hand to address any troubleshooting needs.

5. How long does it take to manufacture and deliver a machine?

The production and delivery timeframe typically range from 4 to 8 weeks, depending on the complexity and customization requirements of the order. SourcifyChina factory strives to meet delivery deadlines and keeps clients informed throughout the process.

6. Are there any warranties offered on these machines?

Yes, all filling and sealing machines from SourcifyChina factory come with a standard one-year warranty. This warranty covers any manufacturing defects and provides full support for repairs or replacements during this period.

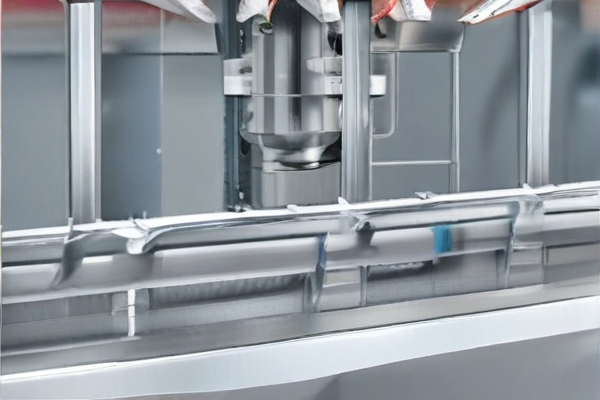

7. What are the energy efficiency and maintenance requirements for these machines?

SourcifyChina factory designs their machines to be energy-efficient and easy to maintain. Regular maintenance procedures are straightforward, and the factory provides detailed guidelines and support to minimize downtime and ensure the machines operate at peak efficiency.

8. How can I place an order with SourcifyChina factory?

You can place an order by contacting SourcifyChina factory directly through their website, email, or phone. Their sales team will assist you with selecting the appropriate machine, customization options, and fulfilling the order process.