1. What types of filling machines does SourcifyChina factory offer?

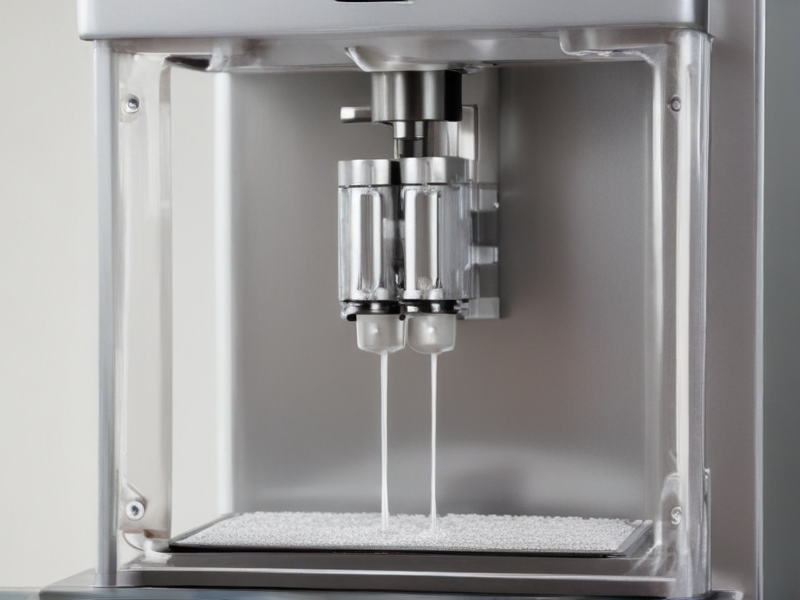

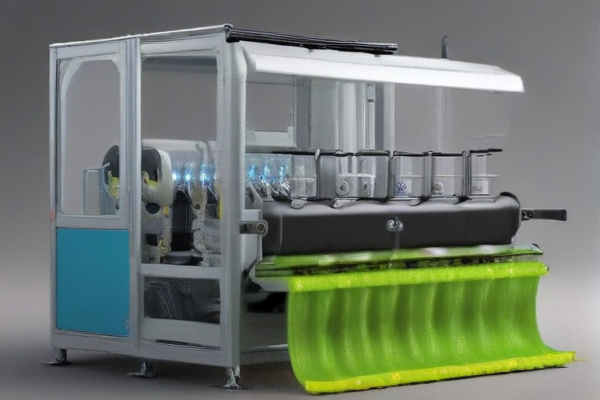

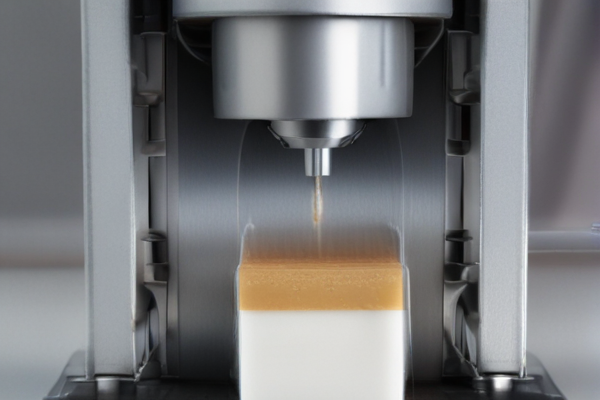

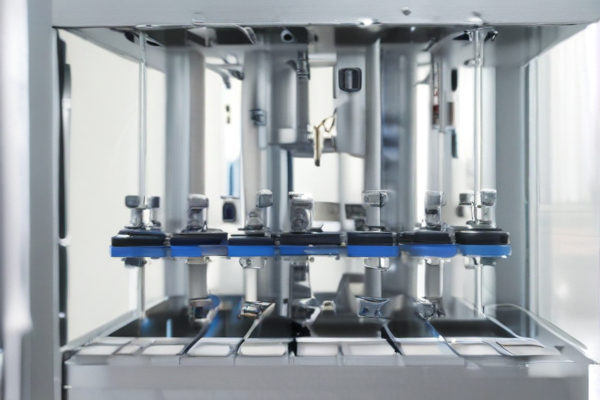

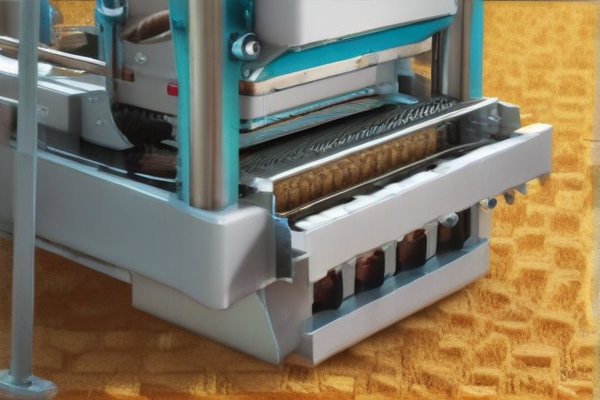

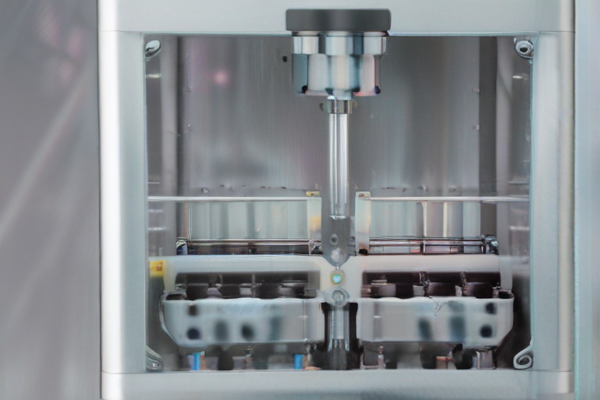

SourcifyChina factory offers a range of filling machines including liquid filling machines, powder filling machines, granule filling machines, and paste filling machines.

2. What materials are used in the construction of the machines?

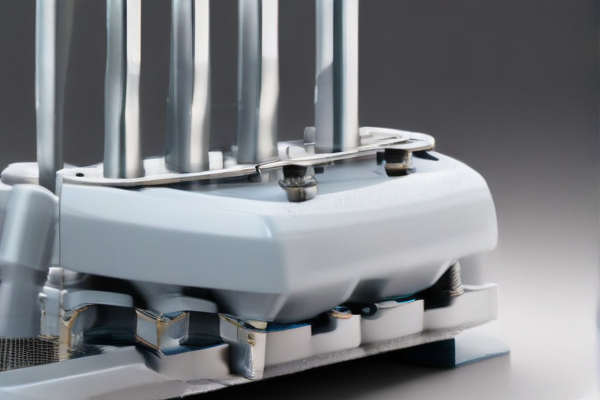

The machines are typically made from high-grade stainless steel to ensure durability, hygiene, and resistance to corrosion.

3. Can the filling machines be customized?

Yes, SourcifyChina provides customization options to meet specific requirements such as different filling capacities, nozzles, and automated systems.

4. What is the lead time for an order?

The lead time varies depending on the complexity and quantity of the order. Typically, it takes around 30 to 45 days for production and delivery.

5. Are there after-sales services available?

SourcifyChina offers comprehensive after-sales services, including installation guidance, technical support, and maintenance services.

6. What is the warranty period for the filling machines?

The machines come with a standard warranty period of one year, covering any manufacturing defects or malfunctions.

7. Do the filling machines comply with international standards?

Yes, the filling machines are designed to comply with international standards such as CE, ISO, and GMP to ensure quality and safety.

8. What are the payment terms?

The common payment terms are T/T (bank transfer), L/C (letter of credit), and sometimes, a negotiation for partial deposits and balance upon delivery.

9. How can I request a quote or place an order?

You can request a quote or place an order by contacting SourcifyChina directly through their official website, email, or phone.

10. Is it possible to visit the factory for an inspection?

Yes, customers are welcome to visit the factory for an inspection. Appointments can be scheduled by contacting SourcifyChina in advance.