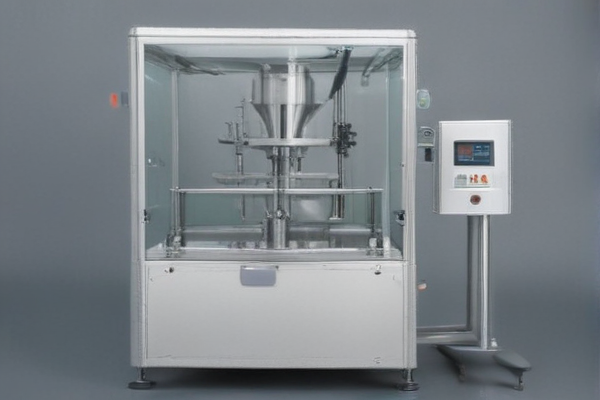

Sure! Here is a list of Frequently Asked Questions (FAQ) for manufacturing a filling machine for powder quality work from SourcifyChina factory:

Q: What types of powders are suitable for the filling machine?

A: The filling machine is suitable for a variety of powders, including pharmaceutical powders, food-grade powders, chemical powders, and cosmetics powders.

Q: What is the filling capacity range for the machine?

A: The filling capacity can range from 10 grams to 10 kilograms, depending on the specific model and customization options.

Q: Is the machine customizable for different production needs?

A: Yes, the machine can be customized to fit specific production requirements such as different filling capacities, speeds, and container types.

Q: What are the safety features of the filling machine?

A: The machine is equipped with safety features like emergency stop buttons, overload protection, and safety guards to ensure operator safety.

Q: What is the average production speed?

A: The production speed varies depending on the model but typically ranges from 20 to 60 units per minute.

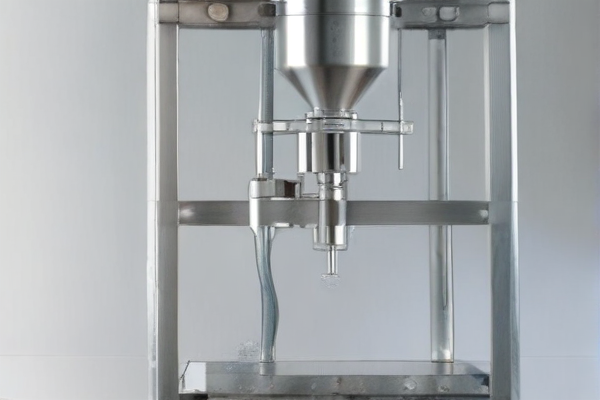

Q: Can the machine handle both free-flowing and non-free-flowing powders?

A: Yes, the machine is designed to handle both free-flowing and non-free-flowing powders effectively.

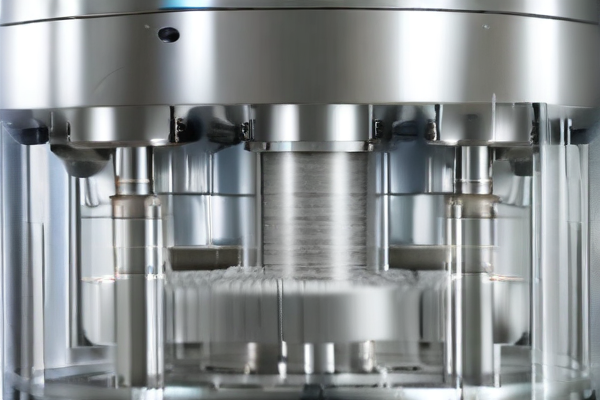

Q: What materials are used in constructing the filling machine?

A: The machine is primarily constructed from high-grade stainless steel, which ensures durability and compliance with hygiene standards.

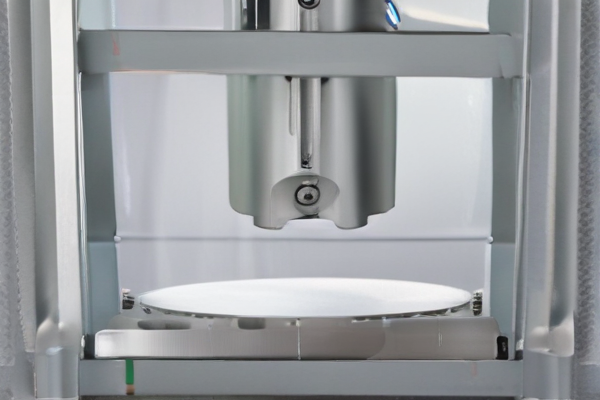

Q: Is the machine easy to clean and maintain?

A: Yes, the design of the filling machine allows for easy disassembly, making it straightforward to clean and maintain.

Q: Does the machine come with a warranty?

A: Yes, SourcifyChina offers a one-year warranty on all filling machines, covering parts and labor.

Q: What after-sales services are available?

A: SourcifyChina provides comprehensive after-sales services, including remote troubleshooting, on-site technical support, and spare parts supply.

Q: How long is the delivery time?

A: The average delivery time is between 6 to 8 weeks from the date of order confirmation.

Q: Is training provided for operating the machine?

A: Yes, SourcifyChina offers training for your staff to ensure efficient and safe operation of the filling machine.