Q: What types of powder filling machines does SourcifyChina factory offer?

A: SourcifyChina factory offers a range of powder filling machines including auger filling machines, vacuum filling machines, and volumetric filling machines. Each type is designed for different levels of precision and types of powder materials.

Q: How accurate are the powder filling machines from SourcifyChina?

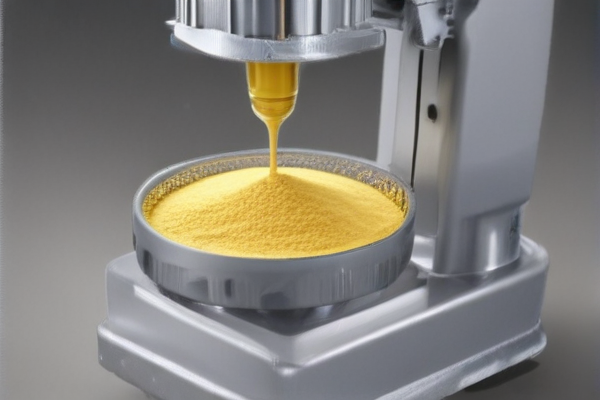

A: Our machines are designed for high precision, typically achieving filling accuracy within ±1% of the target weight, depending on the model and the powder type.

Q: What is the typical production speed of these machines?

A: The production speed varies by model. For instance, our high-speed auger fillers can handle up to 60 containers per minute, while standard models may operate at 30-40 containers per minute.

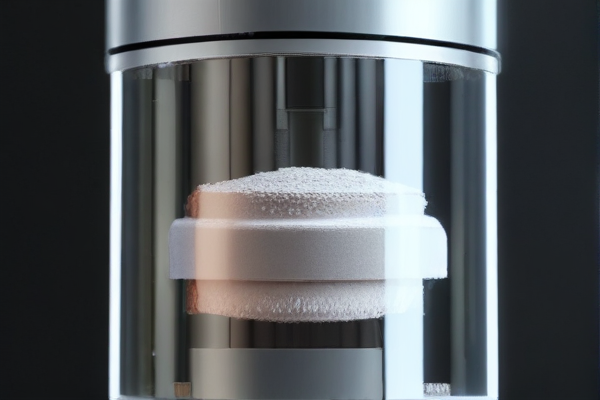

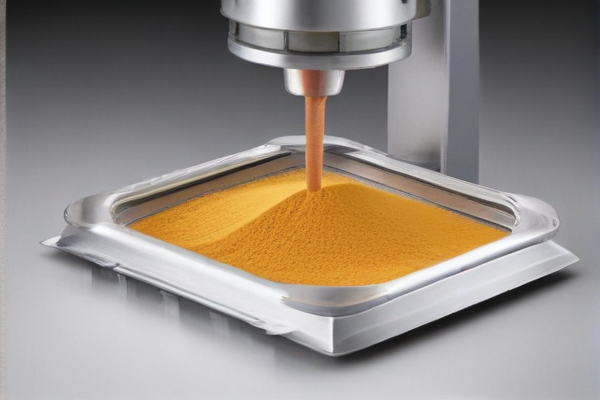

Q: Are the machines compatible with different types of powders?

A: Yes, our powder filling machines are versatile and can handle a wide range of powders, including free-flowing and non-free-flowing types like spices, milk powder, coffee, and protein powders.

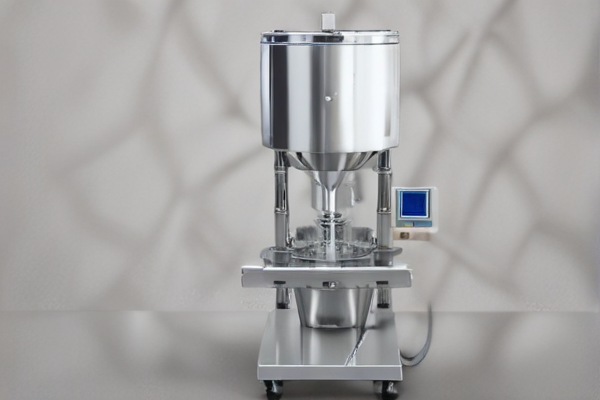

Q: Do SourcifyChina’s machines have user-friendly controls?

A: Absolutely. Each machine comes equipped with an intuitive control panel, often featuring touchscreen interfaces for easy operation and parameter adjustments.

Q: Can the filling machines from SourcifyChina handle different container sizes?

A: Yes, our machines are flexible and can be adjusted to fill various container sizes, ranging from small jars to large bulk containers.

Q: What materials are used in the construction of the machines?

A: Our machines are constructed with high-quality stainless steel to ensure durability, hygiene, and compliance with food safety standards.

Q: Is technical support and service available after purchase?

A: Yes, SourcifyChina offers comprehensive technical support, including installation assistance, maintenance services, and remote troubleshooting to ensure your machines operate smoothly.

Q: How can I get a quote or place an order?

A: You can contact our sales team through the SourcifyChina website or via email. Provide your requirements, and we will offer a detailed quote tailored to your needs.

Q: Are there customization options available?

A: Yes, we offer customization options to match specific production requirements, including machine dimensions, filling capacities, and additional features.