FAQs for Filling Machines Quality Work from SourcifyChina Factory

1. What types of filling machines does SourcifyChina manufacture?

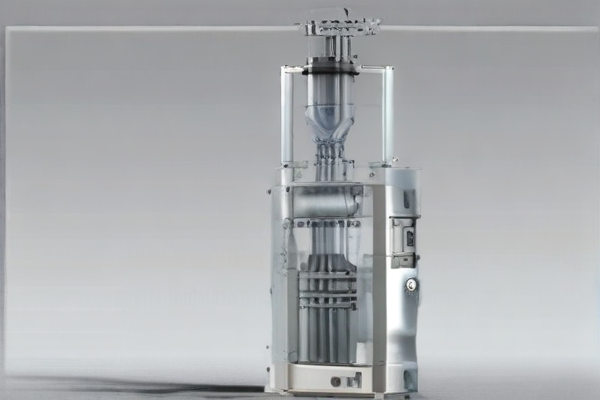

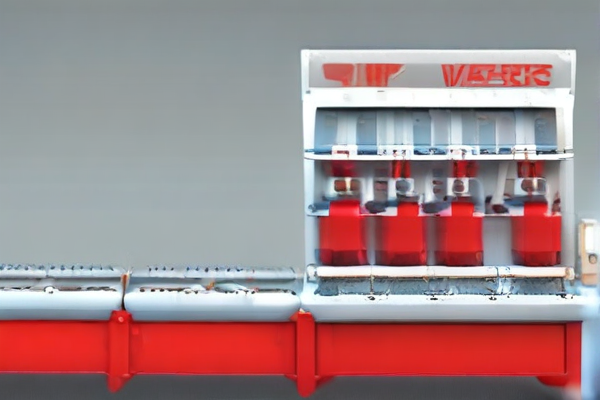

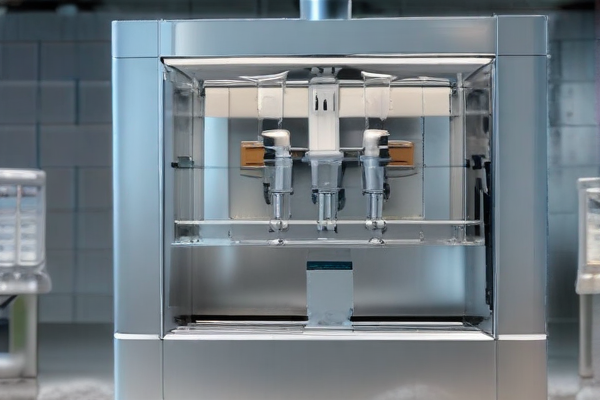

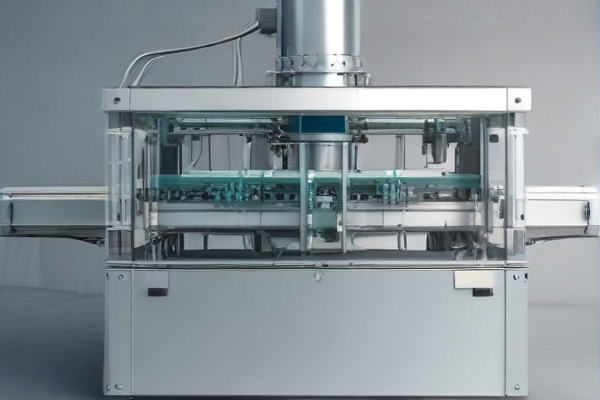

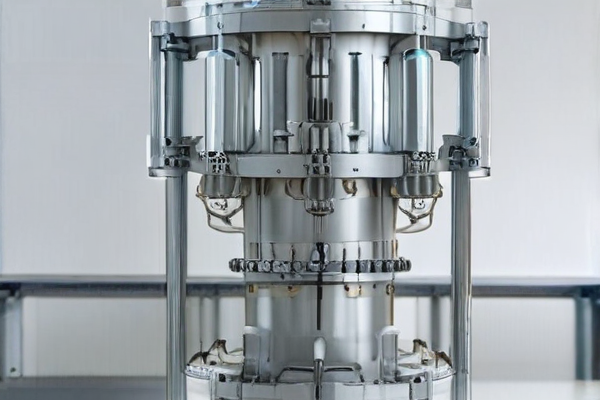

SourcifyChina manufactures a wide range of filling machines, including liquid filling machines, powder filling machines, paste filling machines, and granular filling machines. They cater to various industries such as food & beverage, pharmaceuticals, cosmetics, and chemicals.

2. How do you ensure the quality of the filling machines?

Quality is ensured through stringent control measures including the use of high-grade materials, a robust quality management system, rigorous testing phases, and compliance with international standards like ISO and CE. Each machine undergoes multiple inspections before shipment.

3. Can your filling machines be customized to meet specific requirements?

Yes, SourcifyChina offers customization options. Our team works closely with clients to understand their specific requirements and provide tailored solutions, whether it’s for machine size, filling capacity, or unique features and functionality.

4. Are technical support and training provided?

Absolutely. SourcifyChina provides comprehensive technical support and training. Our experts offer remote and on-site assistance to ensure efficient machine operation, maintenance, and troubleshooting.

5. What is the average lead time for a filling machine order?

The standard lead time for an order varies from 4 to 8 weeks, depending on the machine’s complexity and customization requirements. Express manufacturing options are available for urgent needs.

6. What types of after-sales services are offered?

SourcifyChina provides extensive after-sales services, including warranty coverage, spare parts supply, regular maintenance checks, and prompt support for any operational issues.

7. How do you handle international shipping and installation?

International shipping is managed through a network of reliable logistic partners. SourcifyChina also offers installation services either remotely or by sending our highly skilled technicians to the client’s location.

8. What is the pricing structure for your filling machines?

The pricing varies based on machine type, capacity, and customization level. SourcifyChina aims to offer competitive pricing without compromising on quality. For a precise quote, please contact our sales team.

9. Can I see the filling machines in operation before purchase?

Yes, factory visits are encouraged for potential buyers to see the machines in operation. Additionally, we offer virtual demonstration options for international clients.

10. How can I place an order or get a quote?