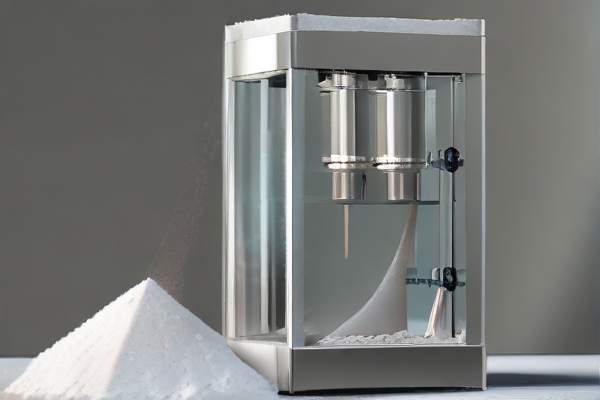

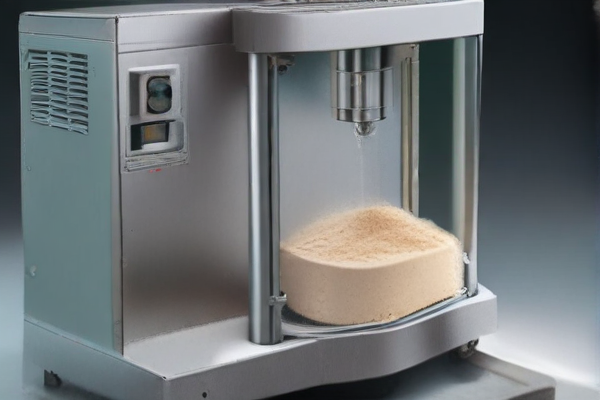

FAQ for Manufacturing “Filling Powder Machine Quality Work” from SourcifyChina Factory

1. What types of powder can the filling machines handle?

The filling machines from SourcifyChina are versatile and can handle a wide range of powders, including food powders, pharmaceuticals, chemicals, and cosmetic powders. They are designed to manage varying particle sizes and flow characteristics.

2. What are the key features of your filling powder machines?

Our filling machines come equipped with precise dosing mechanisms, user-friendly interfaces, robust construction, and high-speed operation. They also feature easy maintenance and adjustment facilities, ensuring long-term efficiency.

3. Are the machines customizable to specific requirements?

Yes, SourcifyChina offers customizable solutions tailored to meet specific client needs, including modifications in size, capacity, and additional features to suit particular applications.

4. What is the typical lead time for a filling powder machine order?

The lead time generally ranges from 4 to 8 weeks, depending on the complexity and customization requirements of the order. We strive to deliver products within the agreed timeline.

5. How do you ensure the quality of the filling machines?

We implement a stringent quality control process that includes inspection of raw materials, in-process quality checks, and comprehensive testing of the final product. Our machines comply with international standards, ensuring top-notch quality.

6. Do you provide after-sales support and service?

Yes, we offer extensive after-sales support, including installation guidance, user training, troubleshooting, and maintenance services. Our dedicated customer support team is always ready to assist.

7. What are the warranty terms for your machines?

Our machines come with a one-year warranty covering any manufacturing defects. We provide free replacements or repairs for parts that fail under normal operating conditions within the warranty period.

8. How energy-efficient are your filling powder machines?

Our machines are designed for optimal energy efficiency, utilizing advanced technologies to minimize power consumption while maintaining high performance and productivity.

9. Can the machines integrate with existing production lines?

Yes, our filling machines can be seamlessly integrated into existing production lines. We provide technical support to ensure smooth integration and minimal disruption to your operations.

10. What safety features are included in your machines?

Safety is a top priority. Our machines come with various safety features, such as emergency stop buttons, protective guards, and automatic shutdown mechanisms in case of malfunction or abnormal operation.