Certainly! Here is a list of frequently asked questions (FAQ) related to the manufacturing quality of filling systems by SourcifyChina factory:

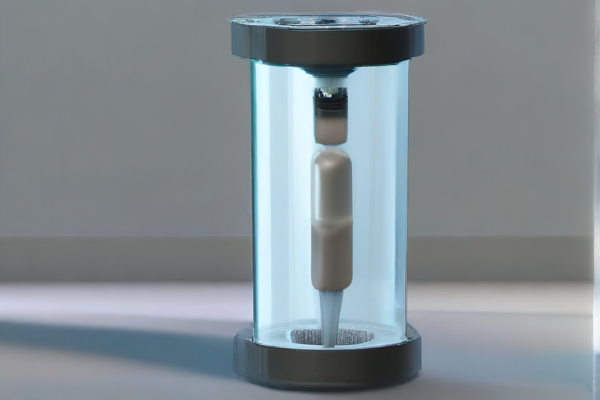

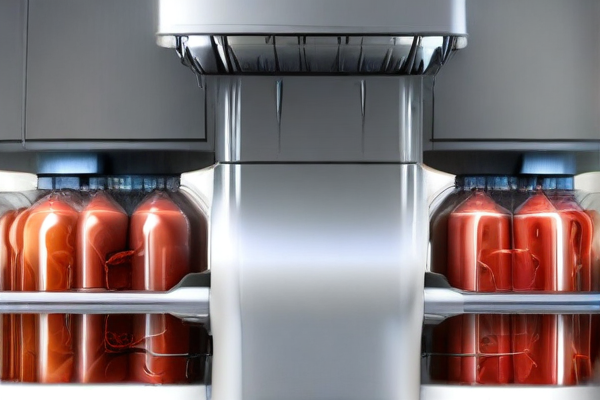

Q1: What types of filling systems does SourcifyChina manufacture?

A1: SourcifyChina specializes in manufacturing a wide range of filling systems, including liquid fillers, powder fillers, granular fillers, and viscous product fillers, tailored to various industry needs.

Q2: How do you ensure the quality of your filling systems?

A2: Quality is ensured through rigorous quality control protocols, which include precision engineering, multiple inspections during the production process, and testing each system under various operational conditions before shipment.

Q3: Can I customize a filling system to meet my specific requirements?

A3: Yes, customization is possible. SourcifyChina works closely with clients to understand their unique needs and provides tailored solutions, from design modifications to selecting specific materials and components.

Q4: What materials are used in your filling systems?

A4: Our filling systems are made using high-grade materials such as stainless steel, aluminum, and food-grade plastics to ensure durability, hygiene, and compliance with industry standards.

Q5: How long does it take to manufacture a custom filling system?

A5: The timeline for manufacturing a custom filling system varies depending on the complexity and specifications of the project. Typically, it ranges from 4 to 12 weeks.

Q6: Do you provide after-sales service and support?

A6: Yes, SourcifyChina offers comprehensive after-sales service, including installation support, maintenance, and remote troubleshooting to ensure smooth operation of the filling systems.

Q7: Are your filling systems energy-efficient?

A7: Absolutely. Our filling systems are designed to be energy-efficient, reducing operational costs and minimizing environmental impact. We utilize advanced technology to achieve this balance.

Q8: What industries do you serve?

A8: SourcifyChina caters to various industries including food and beverage, pharmaceuticals, cosmetics, chemicals, and more, delivering efficient and reliable filling solutions to each sector.

Q9: How can I place an order?

A9: Orders can be placed by contacting our sales team through our official website, email, or phone. We will guide you through the process and ensure all your specifications and requirements are met.

Q10: Do you offer any warranties on your filling systems?