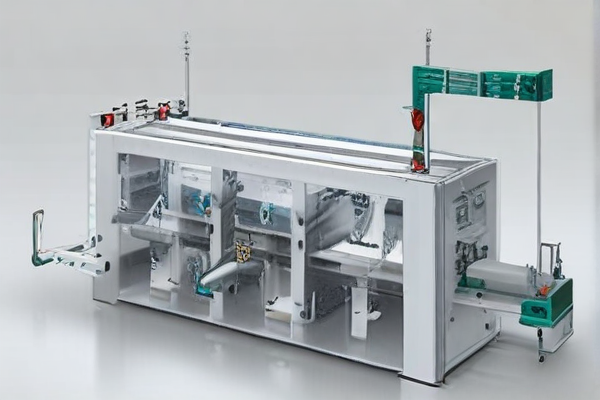

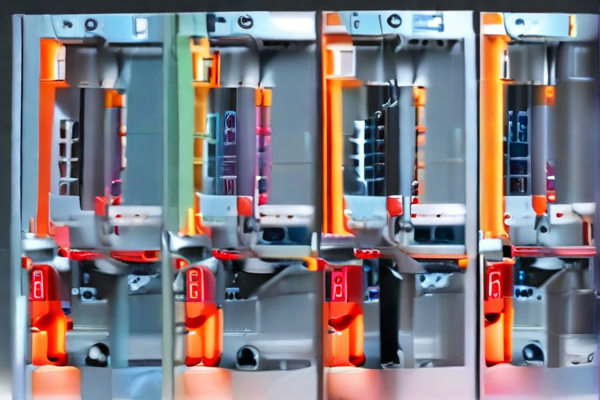

Flexible packaging machines are crucial in various industries, offering versatile packaging solutions for products of different shapes and sizes. These machines enhance efficiency, reduce waste, and improve product shelf life.

– Food Industry: Packaging snacks, dairy products, fresh produce, and frozen goods.

– Pharmaceuticals: Ensuring safe, contamination-free packaging for medicines and medical devices.

– Beverages: Packaging flexible pouches for liquids, including juices and sauces.

– Cosmetics: Packaging creams, lotions, and other personal care products.

– Pet Food: Packaging dry and wet pet foods in various pouch sizes.

– Retail Products: Packaging small hardware items, office supplies, and toys.

– Automotive: Packaging components and small parts for secure transport.

– Agriculture: Packaging seeds, fertilizers, and agrochemicals.

– Electronics: Packaging small electronic components and accessories.

– Medical Supplies: Packaging sterile and non-sterile supplies, including syringes and bandages.

– Household Goods: Packaging detergents, cleaners, and other domestic items.

– Textiles: Packaging clothing items and materials.

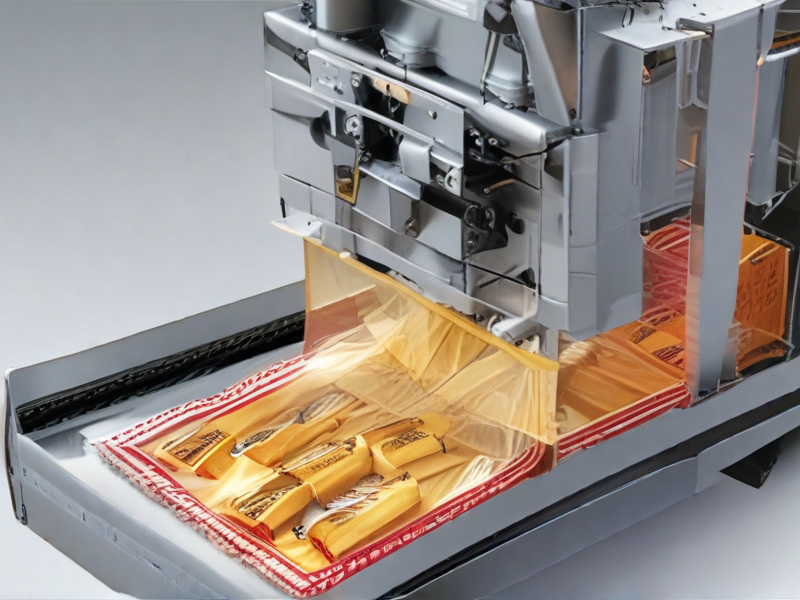

– Confectionery: Packaging candies, chocolates, and baked goods.

– Sports Nutrition: Packaging protein powders, supplements, and energy bars.

– Bakery: Packaging bread, pastries, and baked goods.

– Frozen Foods: Packaging frozen vegetables, meats, and ready meals.

– Spices and Condiments: Packaging spices, seasonings, and sauces.

– Tobacco: Packaging loose tobacco, cigars, and cigarette packs.

– Tea and Coffee: Packaging tea leaves, coffee grounds, and pods.

– Nutraceuticals: Packaging vitamins, minerals, and health supplements.

Flexible packaging machines adapt to various industries’ needs, ensuring product protection, extending shelf life, and providing consumer convenience.