Frequently Asked Questions (FAQ) for Manufacturing Flexible Packaging Machinery Quality Work from SourcifyChina Factory

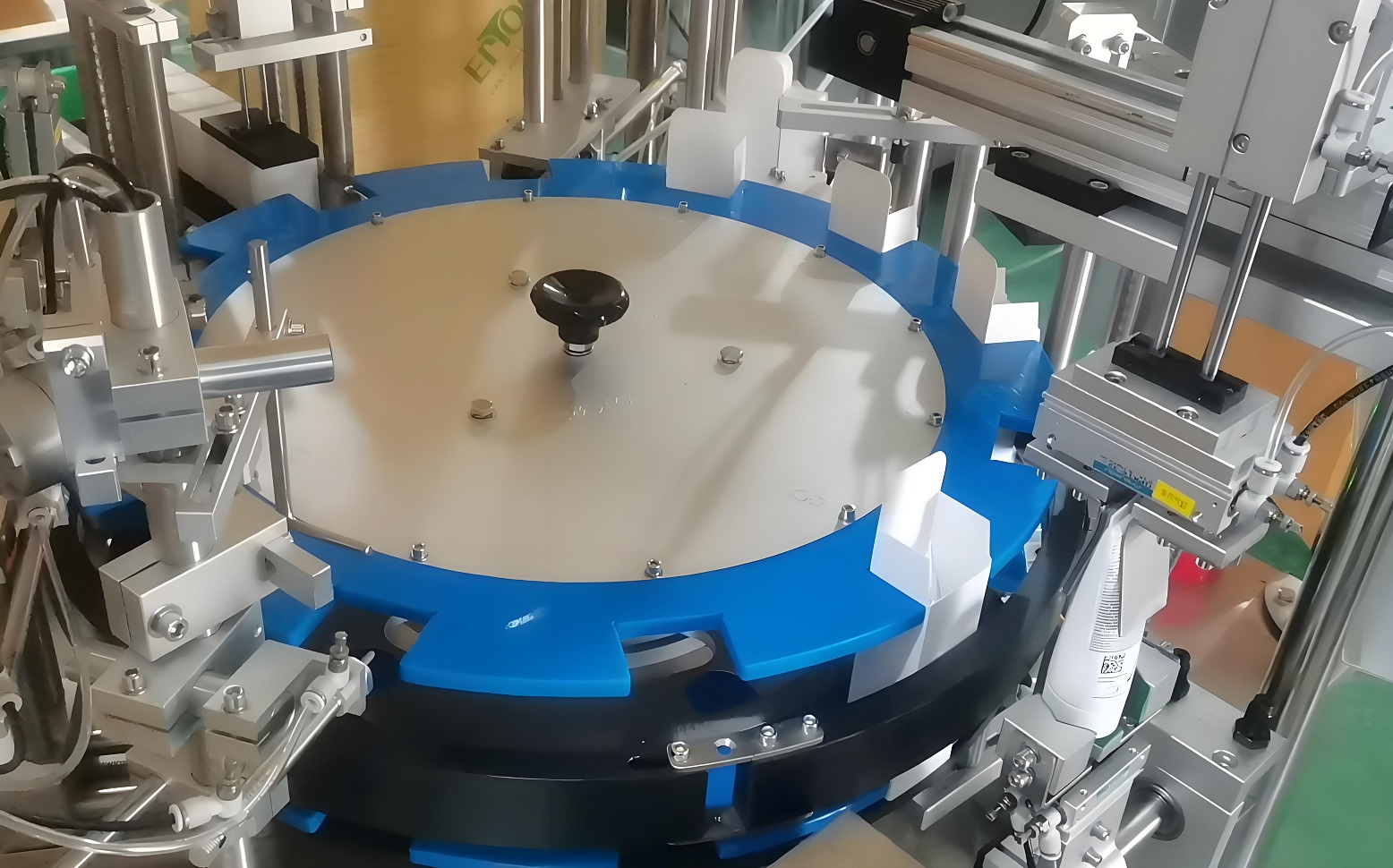

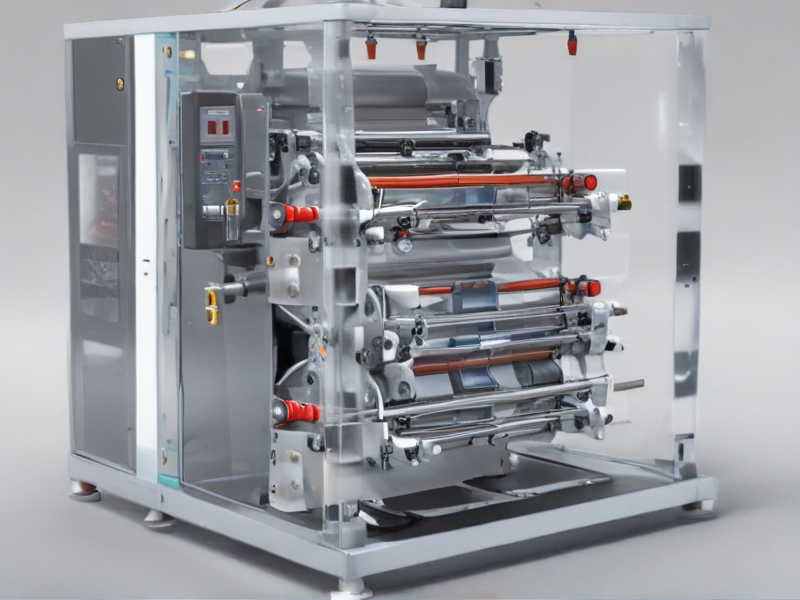

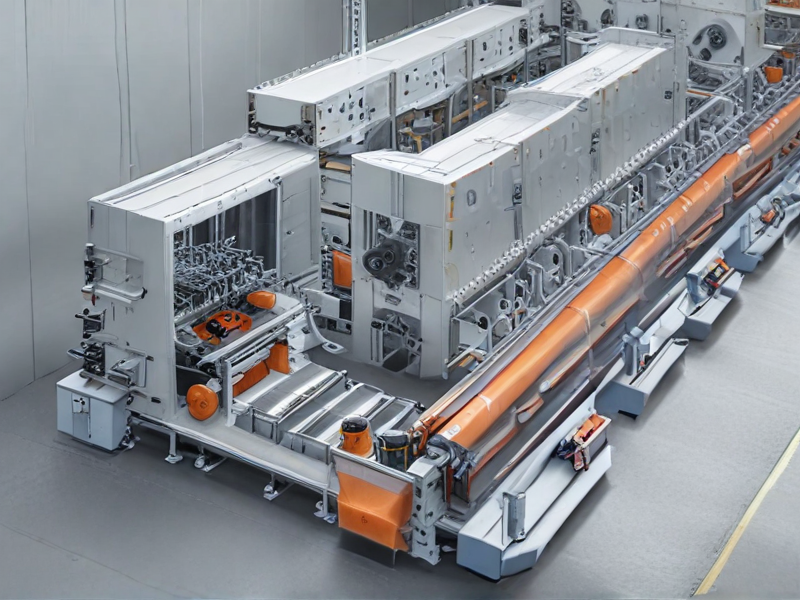

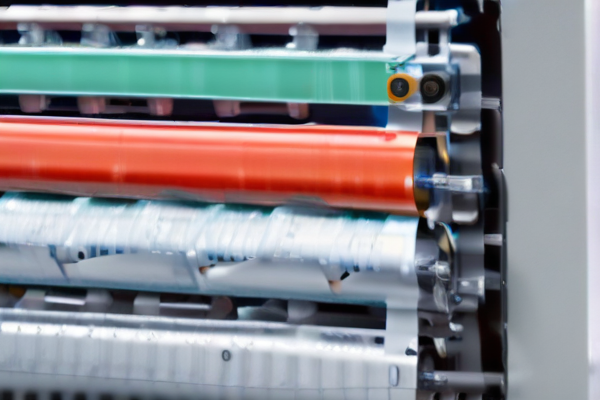

1. What types of flexible packaging machinery do you manufacture?

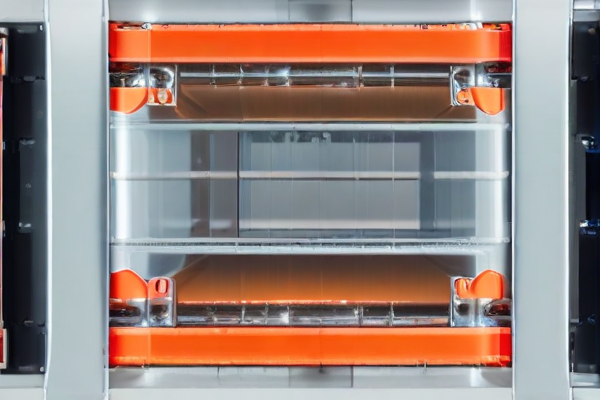

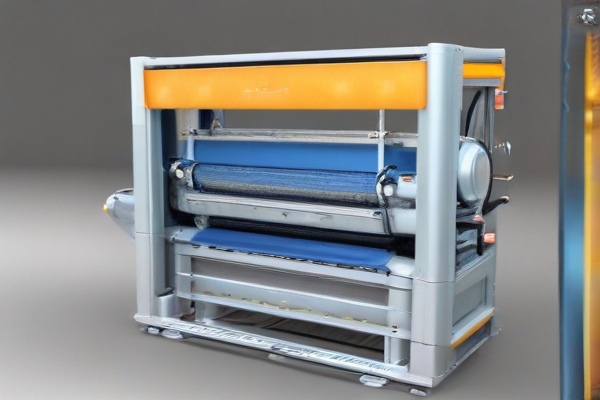

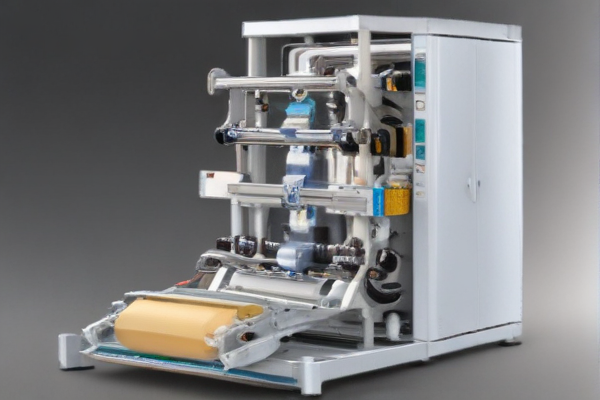

SourcifyChina factory specializes in producing pouch-making machines, form-fill-seal machines, vacuum packaging machines, and laminating machines. Our portfolio ensures we meet diverse packaging needs.

2. How do you ensure the quality of your machines?

We adhere to stringent quality control standards at every production stage, including material selection, precision engineering, and rigorous testing. Our factory is ISO certified, ensuring compliance with international quality norms.

3. Can your machines be customized?

Yes, we offer customization services to tailor our machinery to meet specific client requirements, including size, functionality, and additional features to cater to unique packaging needs.

4. What kind of support do you provide after the purchase?

We provide comprehensive after-sales support, including installation guidance, technical training, maintenance services, and a robust warranty policy to ensure the longevity and efficiency of our machines.

5. How do I place an order with SourcifyChina factory?

To place an order, you can contact our sales team through our website or email us directly. Provide details about your requirements, and our team will guide you through the process.

6. What is your lead time for manufacturing and delivery?

Our standard lead time ranges between 4 to 8 weeks, depending on the complexity and customization of the machinery. We focus on timely delivery without compromising on quality.

7. Are your machines compliant with international standards?

Yes, our flexible packaging machinery is designed and manufactured according to international standards such as CE, ensuring compatibility and safety for global markets.

8. Do you offer training for operating the machines?

Yes, we offer training sessions both on-site and online to ensure your team is proficient in operating and maintaining the machinery efficiently.

9. What payment options do you accept?

We accept multiple payment methods including wire transfers, letters of credit, and other mutually agreed secure payment terms.

10. How can I get a quote for your machinery?

To receive a quote, please fill out the inquiry form on our website or contact our sales team directly with your specific requirements. We’ll provide a detailed quotation promptly.

For further questions, feel free to contact us through our website or email. SourcifyChina factory is committed to providing high-quality packaging solutions tailored to your needs.