1. What types of flour packing machines does PkgMach factory offer?

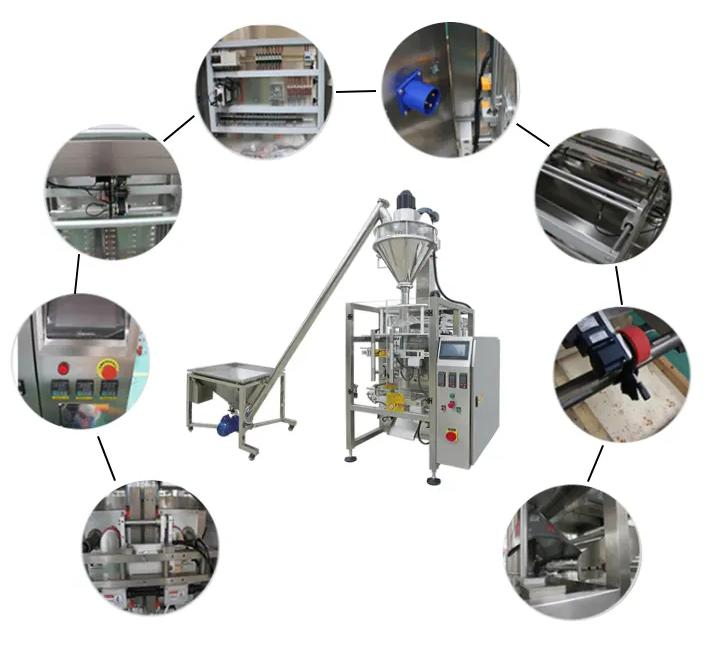

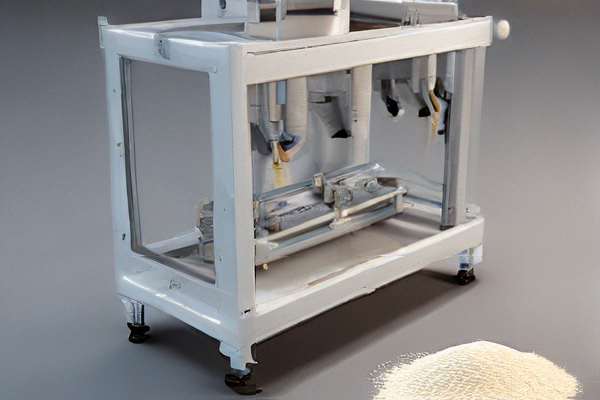

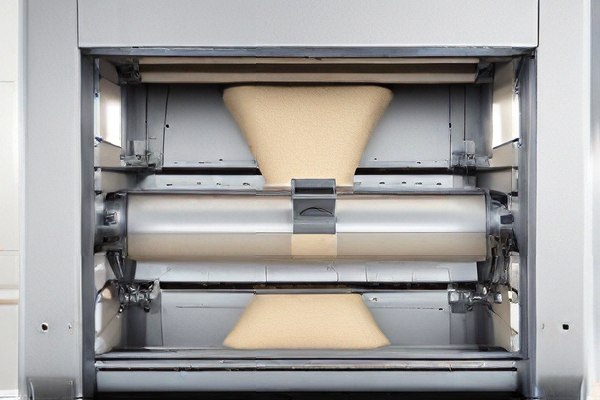

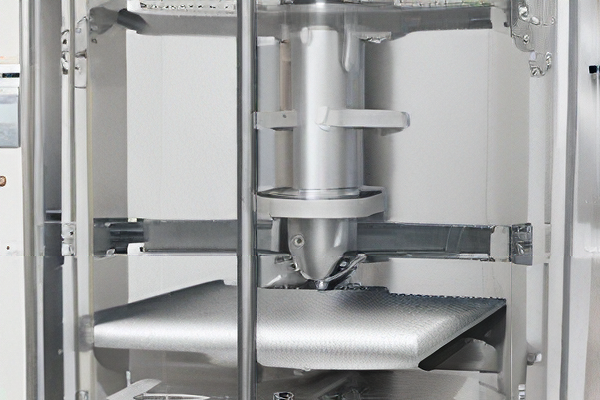

PkgMach factory offers a variety of flour packing machines, including vertical form fill seal machines, auger filling machines, and open mouth bagging machines. These machines are designed to efficiently package flour in various sizes and packaging styles.

2. Can PkgMach factory customize a flour packing machine to meet my specific needs?

Yes, PkgMach factory has the capability to customize flour packing machines to meet specific requirements, such as different packaging sizes, production capacity, and special features. Their team of engineers and technicians will work closely with you to create a machine that fits your exact specifications.

3. What are the advantages of sourcing a flour packing machine from PkgMach factory?

Sourcing a flour packing machine from PkgMach factory ensures high-quality equipment that is durable, efficient, and reliable. Their machines are designed for easy operation, maintenance, and cleaning, helping to streamline production processes and reduce downtime.

4. Does PkgMach factory provide installation and training services for their flour packing machines?

Yes, PkgMach factory offers installation and training services for their flour packing machines. Their experienced technicians will set up the equipment at your facility and provide comprehensive training to your staff on how to operate and maintain the machine effectively.

5. Is PkgMach factory able to provide after-sales support and spare parts for their flour packing machines?

Yes, PkgMach factory offers after-sales support and has a stock of spare parts readily available for their flour packing machines. Their customer service team is responsive and dedicated to ensuring that your equipment operates smoothly and efficiently over its lifespan.