Sure, here are some frequently asked questions (FAQ) with answers for manufacturing a “flow pack machine quality work from SourcifyChina factory”:

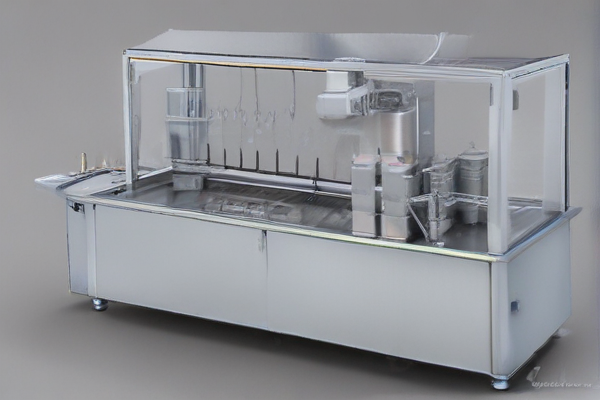

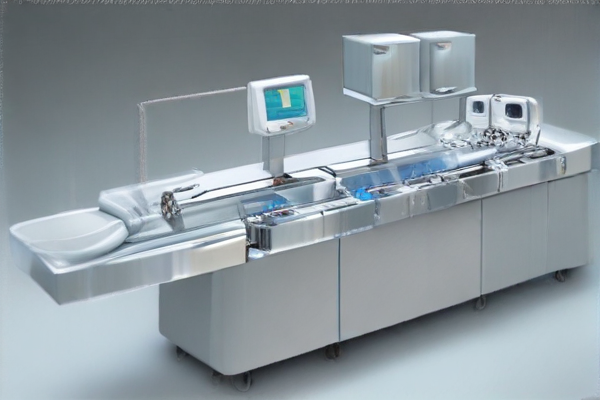

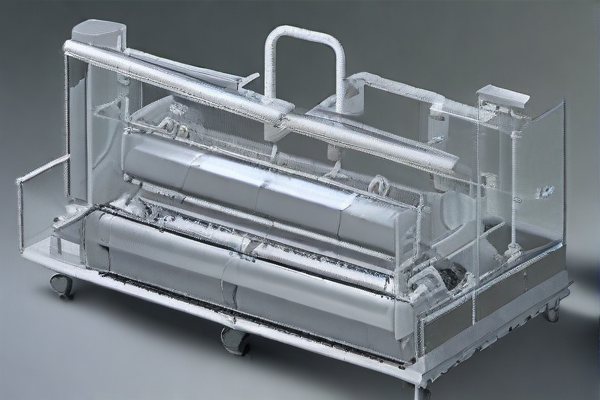

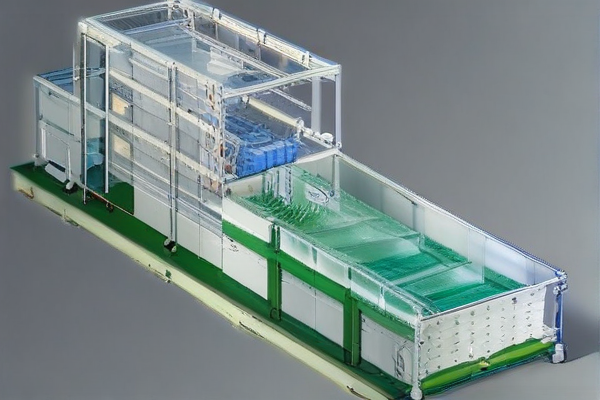

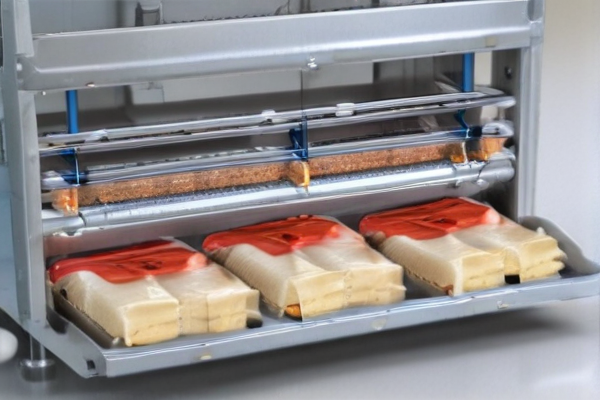

Q1: What is a flow pack machine?

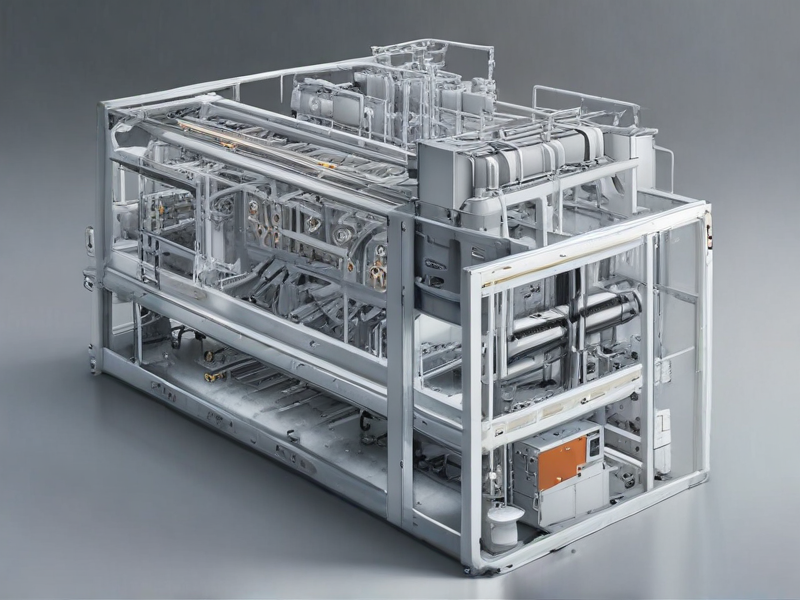

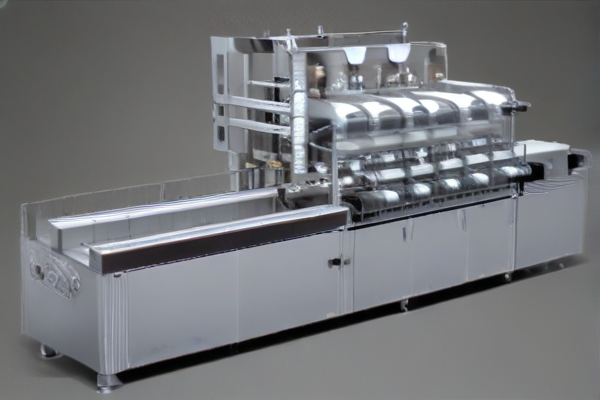

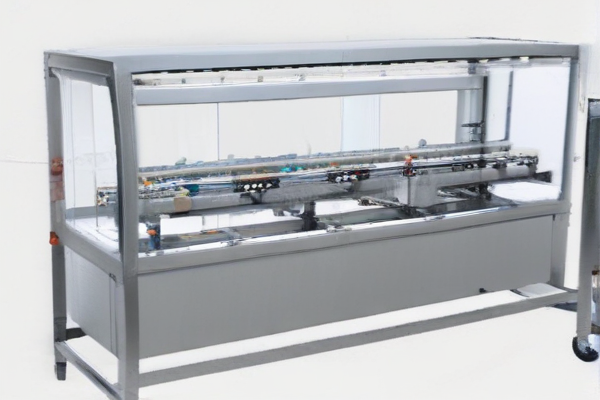

A1: A Flow Pack Machine, also known as a Horizontal Form-Fill-Seal (HFFS) machine, is used for packaging products in a plastic film, creating a tight seal and protecting contents from contaminants.

Q2: What types of products can be packaged using a flow pack machine?

A2: Flow pack machines are versatile and can package a variety of products including food items (snacks, biscuits, candies), pharmaceuticals, medical devices, and consumer goods.

Q3: Why should I choose SourcifyChina for my flow pack machine needs?

A3: SourcifyChina is renowned for its high-quality manufacturing standards, advanced technology, cost-effective solutions, and excellent after-sales service, ensuring you receive a reliable and efficient product.

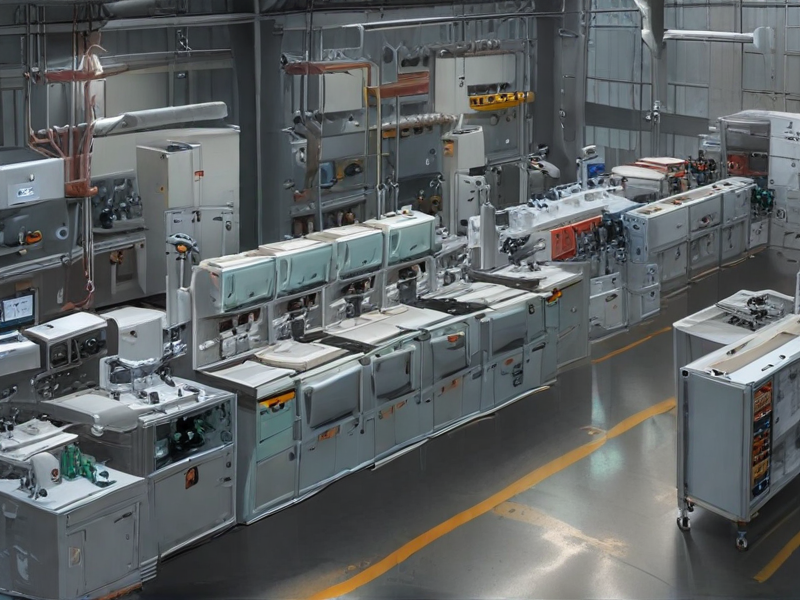

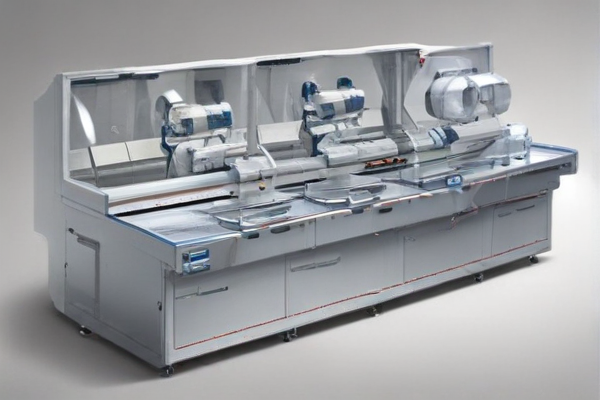

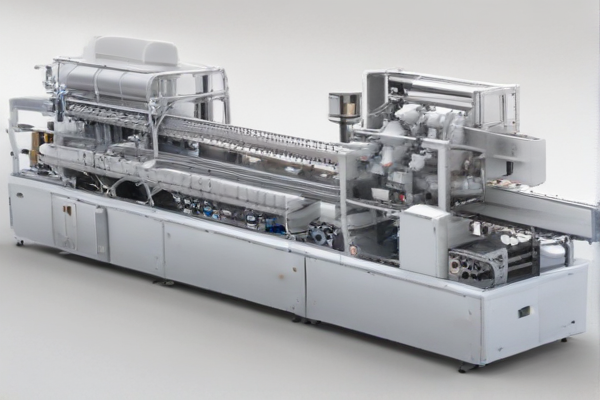

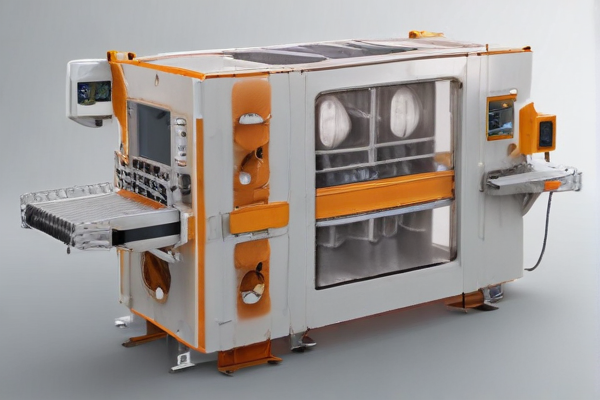

Q4: What are the main features of the flow pack machines from SourcifyChina?

A4: Key features include high-speed operation, automatic film feeding and cutting, user-friendly interface, flexibility in packaging various product sizes, and robust construction for durability.

Q5: How do you ensure the quality of the flow pack machines?

A5: SourcifyChina implements rigorous quality control measures including material inspection, in-process checks, and final product testing to ensure the machines meet international standards.

Q6: Are SourcifyChina flow pack machines customizable?

A6: Yes, SourcifyChina offers customization options to meet specific packaging needs, including alterations in size, speed, material compatibility, and additional functionalities as per client requirements.

Q7: What kind of after-sales support does SourcifyChina provide?

A7: SourcifyChina offers comprehensive after-sales support including installation assistance, training, maintenance services, and technical support to ensure the smooth operation of the machines.

Q8: How long does it take to deliver a flow pack machine from SourcifyChina?

A8: Delivery times may vary based on customization needs and order volume, but typical lead times range from 4 to 8 weeks after order confirmation.

Q9: What is the warranty period for flow pack machines from SourcifyChina?