Sure! Here are some frequently asked questions (FAQ) and answers regarding the quality of flow wrap machines manufactured by SourcifyChina Factory:

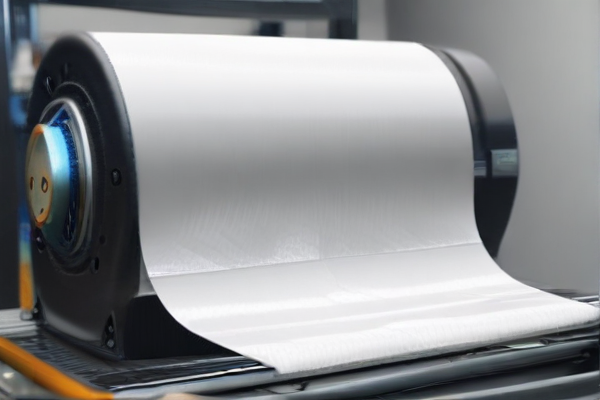

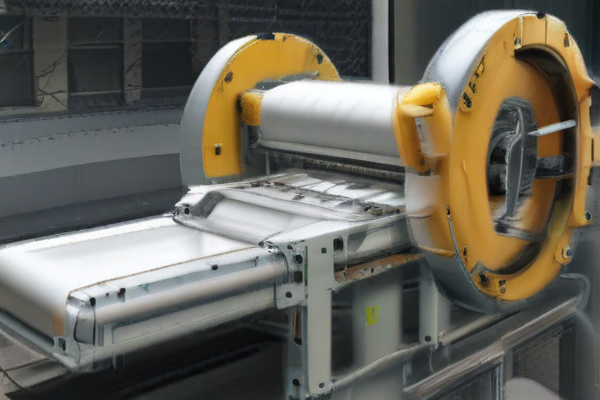

Q: What materials are used in manufacturing the flow wrap machines at SourcifyChina?

A: SourcifyChina utilizes high-grade stainless steel and durable industrial components to ensure the longevity and reliability of our flow wrap machines.

Q: How does SourcifyChina ensure the quality of its flow wrap machines?

A: Quality is ensured through stringent quality control processes, including multiple checks during the production process, final testing, and adherence to international manufacturing standards.

Q: Are the flow wrap machines from SourcifyChina customizable?

A: Yes, SourcifyChina offers customization options to meet specific client requirements, including size, speed, and additional features.

Q: Do SourcifyChina’s flow wrap machines come with a warranty?

A: Yes, all our flow wrap machines come with a comprehensive warranty that covers manufacturing defects and offers after-sales support.

Q: Can I see a demo of the flow wrap machine before purchasing?

A: Absolutely! SourcifyChina provides live demos, either in-person at our factory or through video conferencing, to help you understand the machine’s capabilities.

Q: What kind of technical support does SourcifyChina offer?

A: We provide 24/7 technical support, including remote assistance and on-site service when necessary, to ensure that your machine runs smoothly.

Q: How long does it take to deliver a flow wrap machine?

A: Delivery time typically ranges from 4 to 6 weeks, depending on the customizations and current order volume.

Q: Are there any specific power requirements for the flow wrap machines?

A: Our machines are designed to be compatible with standard industrial power supplies. Specific electrical requirements can be accommodated upon request.

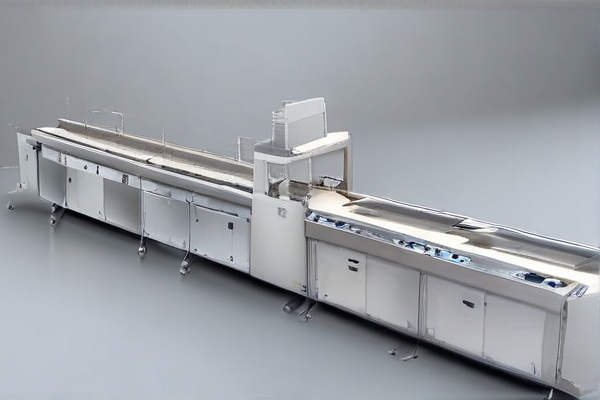

Q: What industries commonly use SourcifyChina’s flow wrap machines?

A: Our flow wrap machines are widely used in the food, pharmaceutical, and consumer goods industries for packaging a variety of products.

Q: How do I place an order with SourcifyChina?

A: To place an order, please contact our sales team via email or phone. They will guide you through the process, including discussing specifications, customization options, and payment terms.