FAQ for Manufacturing Flow Wrap Packing Machine Quality Work from SourcifyChina Factory

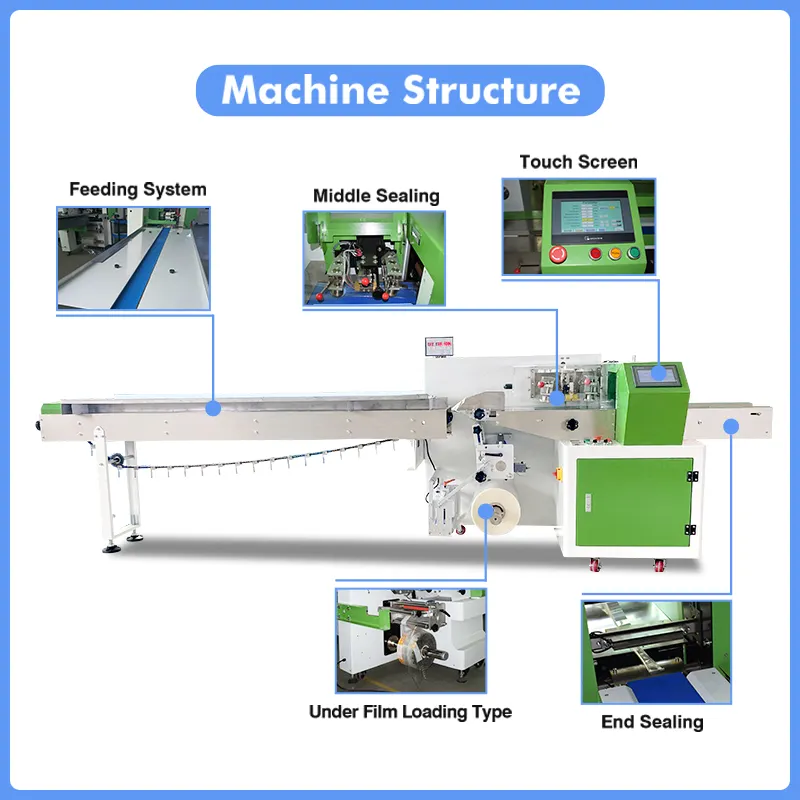

1. What is a flow wrap packing machine?

A flow wrap packing machine is a type of packaging machinery that wraps products in a continuous film. The machine forms a bag around the product, seals it, and then cuts off the packed product from the rest of the film.

2. What quality standards does SourcifyChina Factory follow?

SourcifyChina Factory adheres to international quality standards like ISO 9001:2015 and boasts multiple certifications such as CE and GMP, ensuring that our machines meet high-quality and safety requirements.

3. What types of products can be packed using your flow wrap machines?

Our flow wrap packing machines are versatile and can pack a variety of products including food items, pharmaceuticals, cosmetics, and industrial products.

4. What materials can be used for wrapping on these machines?

Common materials include polypropylene (PP), polyethylene (PE), aluminum foil, and biodegradable films. The choice of material depends on the specific requirements of the product being packed.

5. Can SourcifyChina customize machines based on specific requirements?

Yes, we specialize in creating customized solutions to meet our clients’ unique needs. Each machine can be tailored based on the product dimensions, speed requirements, and packaging materials.

6. What is the typical lead time for delivery?

The lead time for our flow wrap packing machines typically ranges from 4 to 8 weeks, depending on the complexity and customization requirements.

7. Do you provide after-sales services and support?

Yes, SourcifyChina offers comprehensive after-sales support including installation, training, maintenance, and remote technical assistance.

8. How can I ensure the machine’s longevity and optimal performance?

Regular maintenance is key. We provide a detailed maintenance manual and offer periodic service visits to ensure your machine operates effectively and efficiently.

9. What are the payment terms available?

We offer flexible payment terms including T/T, L/C, and sometimes even phased payments for large projects. Detailed terms can be discussed during the negotiation phase.

10. How can I get a quote or place an order?

You can contact us directly via our website, email, or phone. Provide us with your specific requirements, and our team will present a detailed quote and guide you through the ordering process.