Certainly! Below are some FAQs with answers regarding the quality of flow wrapper machines manufactured by SourcifyChina factory:

Q: What quality standards does SourcifyChina adhere to for flow wrapper machines?

A: SourcifyChina adheres to international quality standards, including ISO 9001 and CE certifications, ensuring that their machines meet global performance and safety requirements.

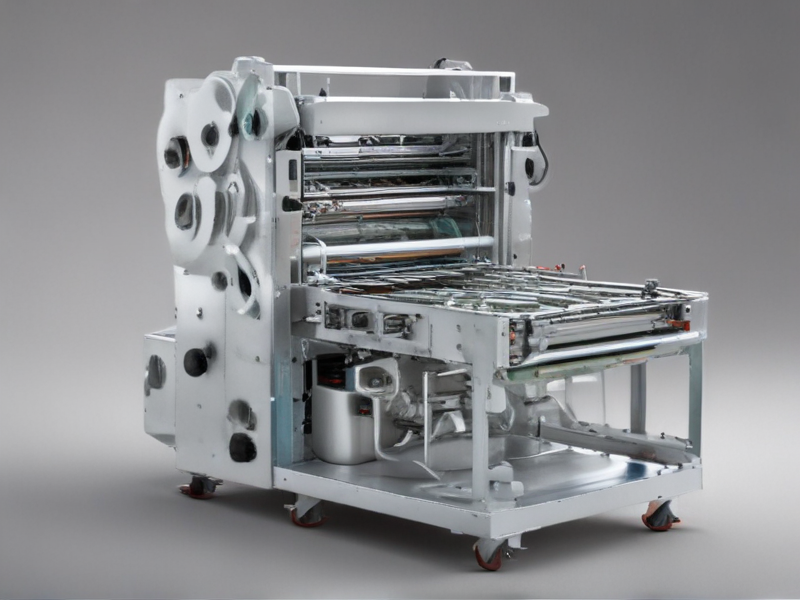

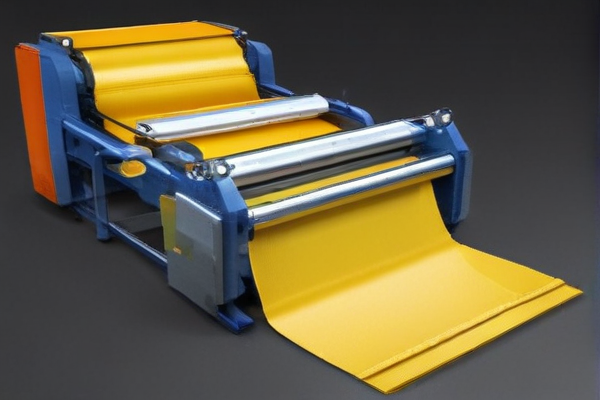

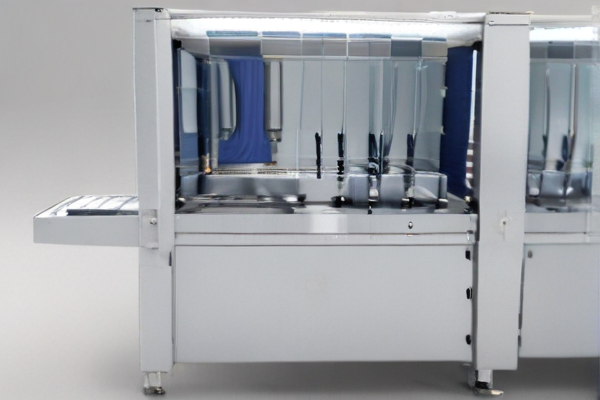

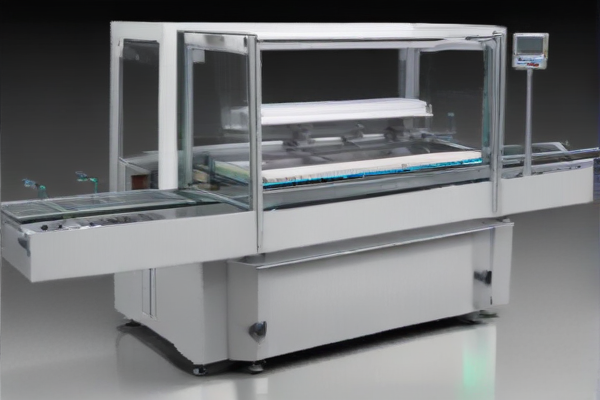

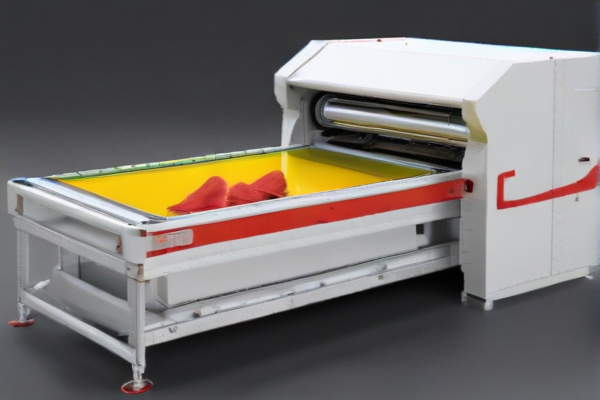

Q: What materials are used in the construction of SourcifyChina’s flow wrapper machines?

A: High-grade stainless steel and industrial-grade components are used in the construction to ensure durability, hygienic processing, and longevity.

Q: Are SourcifyChina’s flow wrapper machines customizable for different packaging needs?

A: Yes, SourcifyChina offers customization options to suit various packaging requirements including size, speed, and specialized features for specific products.

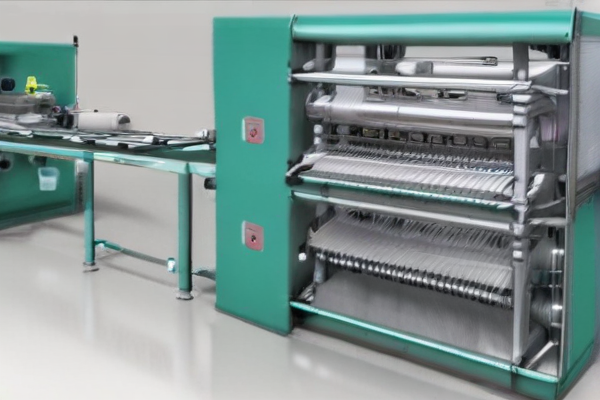

Q: How does SourcifyChina ensure the reliability of their flow wrapper machines?

A: Comprehensive testing and quality control processes are in place, including stress testing and performance assessments, to ensure reliable operation under different conditions.

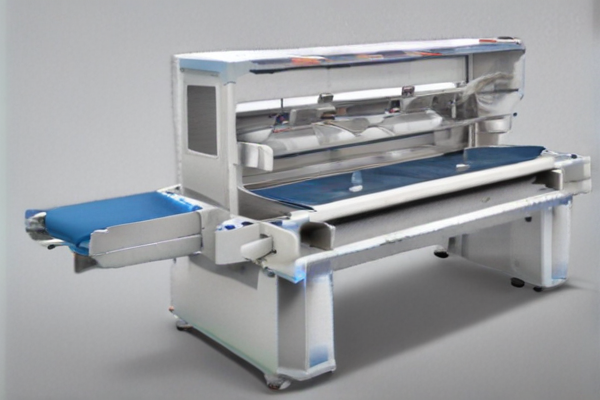

Q: What types of products can be packaged using SourcifyChina’s flow wrapper machines?

A: Their flow wrapper machines are versatile and can package a variety of products such as food items, pharmaceuticals, and consumer goods.

Q: How user-friendly are the flow wrapper machines from SourcifyChina?

A: The machines are designed with intuitive interfaces and user-friendly controls, making them easy to operate and maintain, even for less experienced operators.

Q: Does SourcifyChina provide after-sales support and maintenance services?

A: Yes, they offer comprehensive after-sales support including installation, training, troubleshooting, and regular maintenance to ensure peak performance.

Q: What is the average lead time for delivery of a flow wrapper machine from SourcifyChina?

A: The lead time for delivery typically ranges from 4 to 8 weeks, depending on customization requirements and order volume.

Q: How energy-efficient are the flow wrapper machines from SourcifyChina?

A: SourcifyChina prioritizes energy efficiency in their design, incorporating advanced technologies that reduce power consumption without compromising performance.

Q: Can SourcifyChina provide references or case studies of their machines in operation?

A: Yes, they can provide references and case studies upon request, showcasing the successful implementation of their machines in various industries.