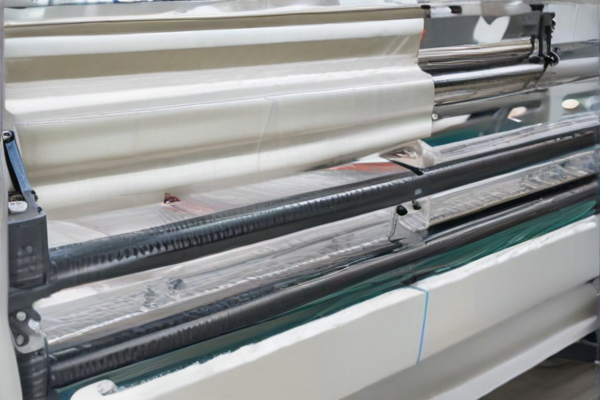

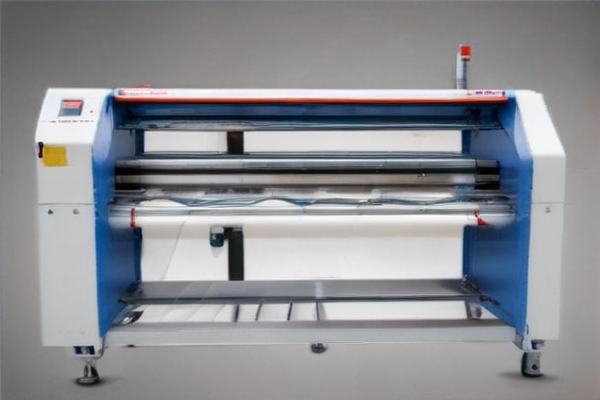

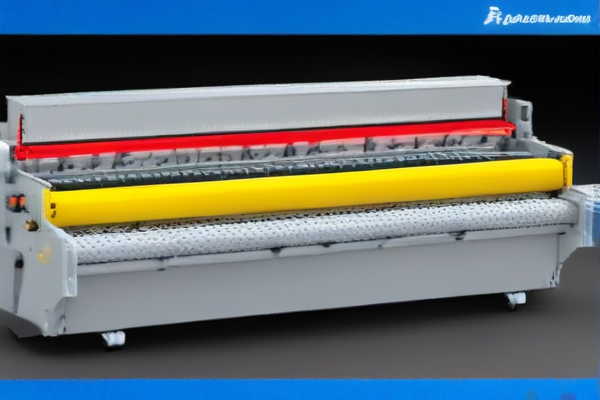

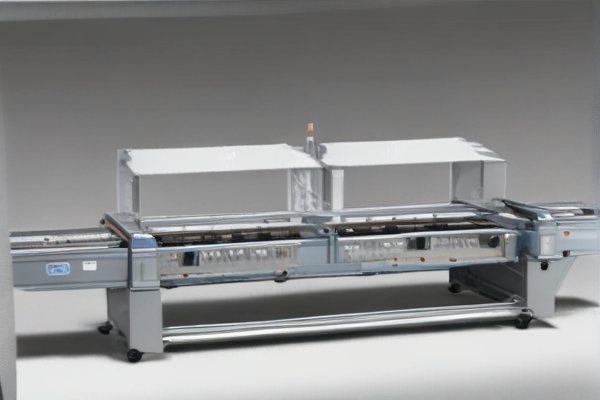

Flow wrapping machines are versatile packaging systems designed for wrapping products in a continuous flow of film. They come in different types and offer various options to suit specific industries and product requirements, ensuring an efficient and reliable packaging process.

Types and options for flow wrapping machines:

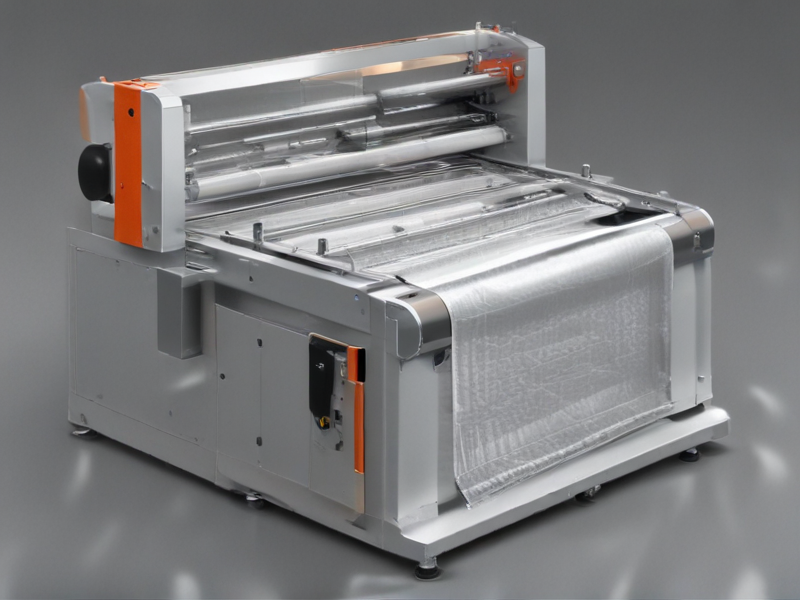

– Horizontal Flow Wrappers (HFFS):

– Ideal for solid, semi-solid, and irregularly shaped products.

– Can handle high-speed operations.

– Suitable for food items like candies, biscuits, and pharmaceuticals.

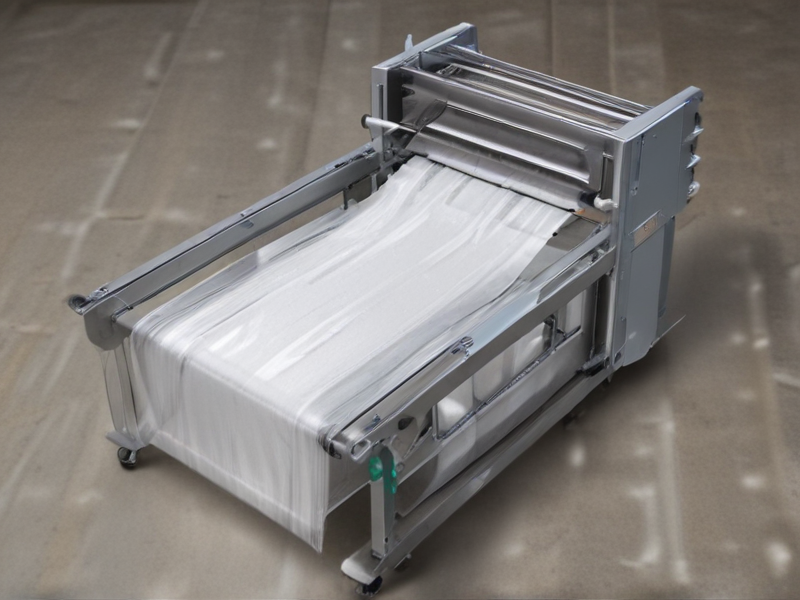

– Vertical Flow Wrappers (VFFS):

– Designed for bulkier or granular items.

– Often used in the packaging of snacks, coffee, and other granulated products.

– Efficient in minimizing film waste.

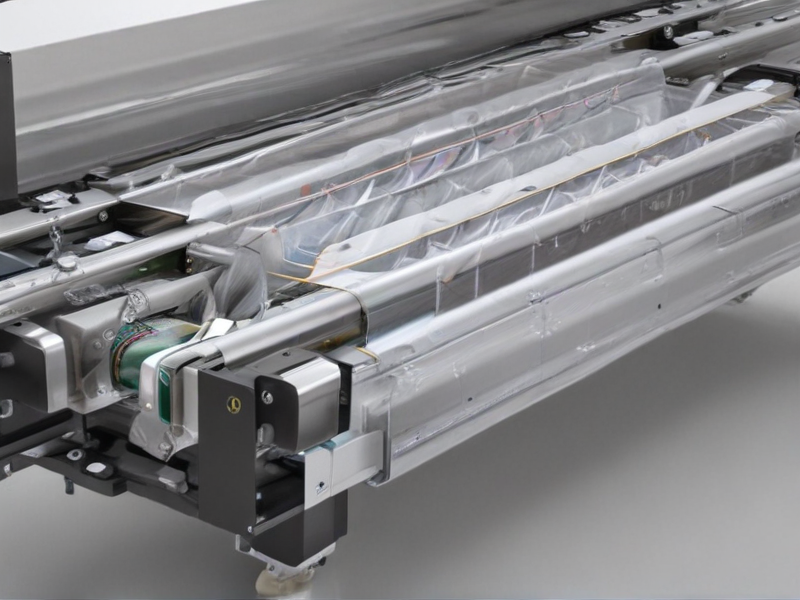

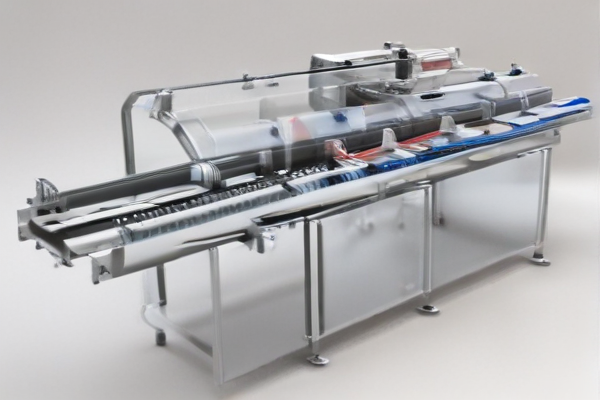

– Rotary Jaw Flow Wrapper:

– Features rotating jaws for sealing.

– High speed with shorter dwell times.

– Commonly used for bakery items, confectionery, and personal care products.

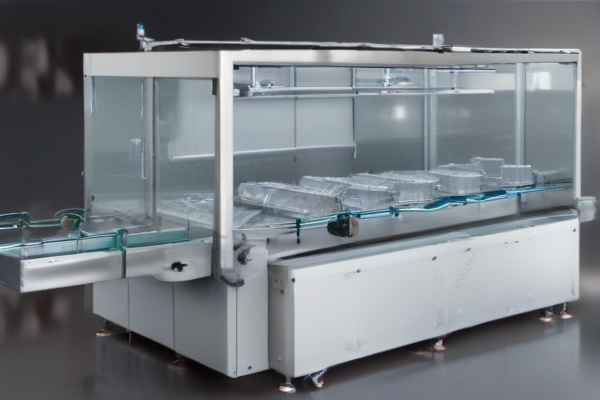

– Box Motion Flow Wrapper:

– Provides a tighter seal, ideal for gas-flushed packs.

– Suited for meat, cheese, and frozen foods.

– Enhanced film control for delicate items.

Options for customization:

– Film Types:

– Polyethylene, polypropylene, and barrier films for different product protections.

– Printed or clear films for branding and visibility.

– Sealing Techniques:

– Cold sealing for temperature-sensitive products.

– Heat sealing for a stronger and more hermetic seal.

– Feed Systems:

– Automatic infeed for continuous operation.

– Manual feed for smaller operations or niche products.

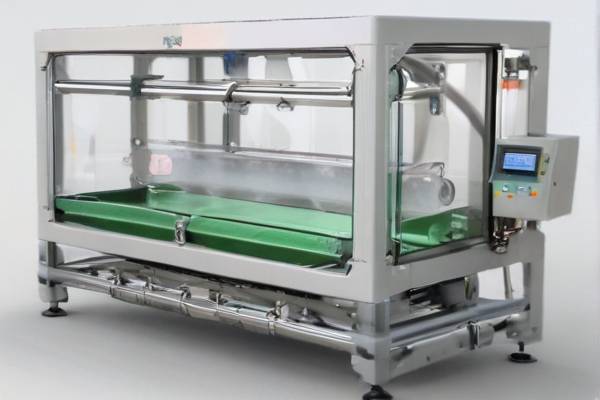

– Control Systems:

– Advanced PLC controls for automation and precision.

– User-friendly HMI for easy adjustments and monitoring.

– Product Inspection and Rejection Systems:

– Ensures quality control with mechanisms for detecting and rejecting defective packages.

Flow wrapping machines can be tailored to meet specific needs, ensuring efficient and high-quality packaging for a wide range of products.