Sure! Here are some Frequently Asked Questions (FAQ) for sourcing quality flow wrapping machines from the SourcifyChina factory:

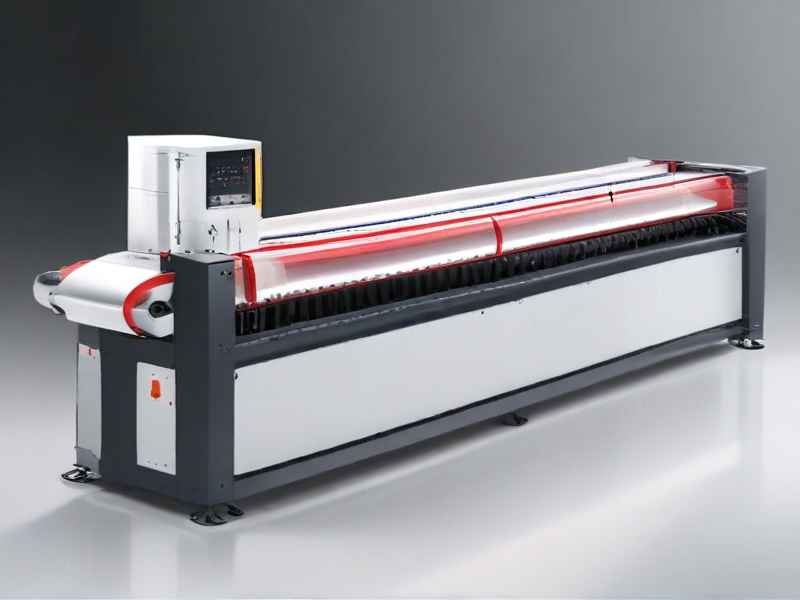

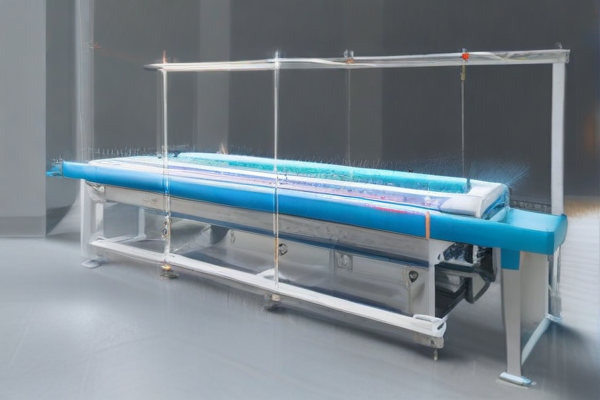

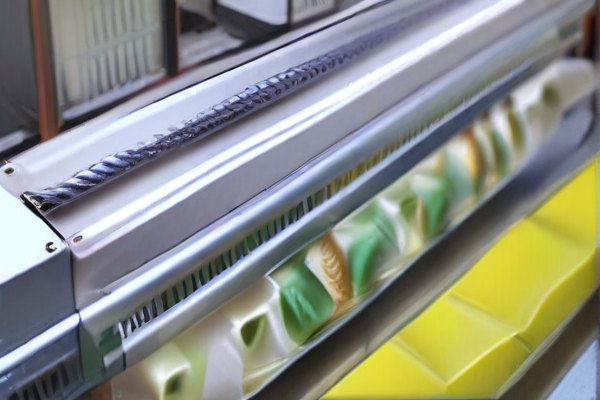

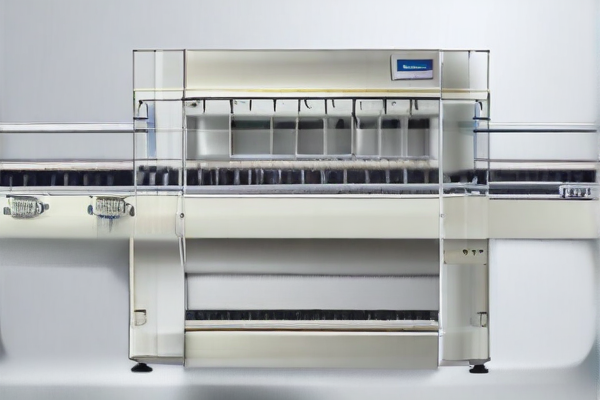

1. What is a flow wrapping machine?

A flow wrapping machine is a packaging machine that wraps products in a continuous roll of film, forming a tight seal and protecting the product from contamination. It is widely used in food, confectionery, and pharmaceutical industries.

2. Why should I choose a flow wrapping machine from SourcifyChina factory?

SourcifyChina factory is known for its high-quality manufacturing standards, competitive pricing, and reliable customer service. Their machines are built to last and meet international safety and efficiency standards.

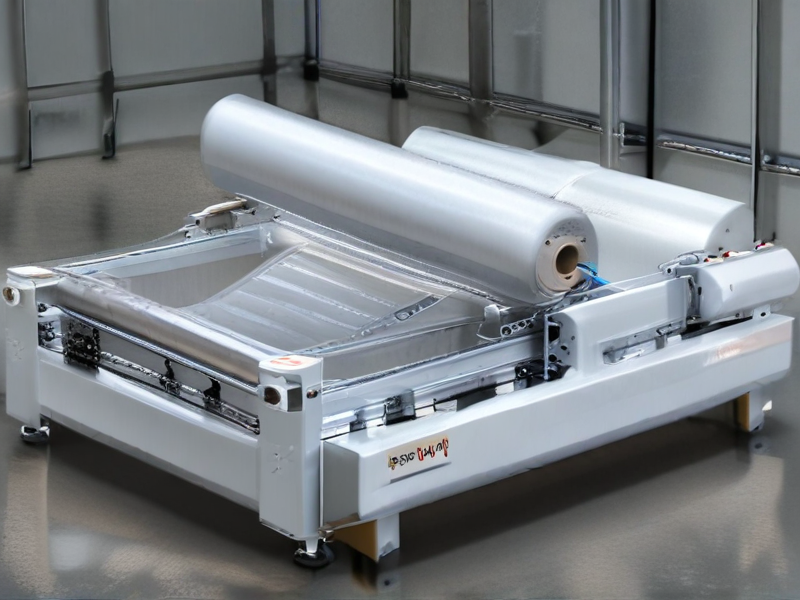

3. What materials can the flow wrapping machine handle?

The machine can handle a variety of films, including polyethylene, polypropylene, and laminated films. It’s versatile and can be adjusted according to the specific needs of your product.

4. How can I ensure the quality of the machine before purchasing?

SourcifyChina factory offers a comprehensive quality assurance process, including factory audits, sample testing, and rigorous inspections. You can also request certification and compliance documentation.

5. What are the lead times for production and delivery?

Lead times vary depending on the machine specifications and order quantity. Typically, it takes between 4 to 8 weeks for production, plus additional shipping time based on your location.

6. What kind of after-sales support is provided?

SourcifyChina factory offers extensive after-sales support, including installation guidance, operator training, and ongoing technical assistance. Spare parts and maintenance services are also available as needed.

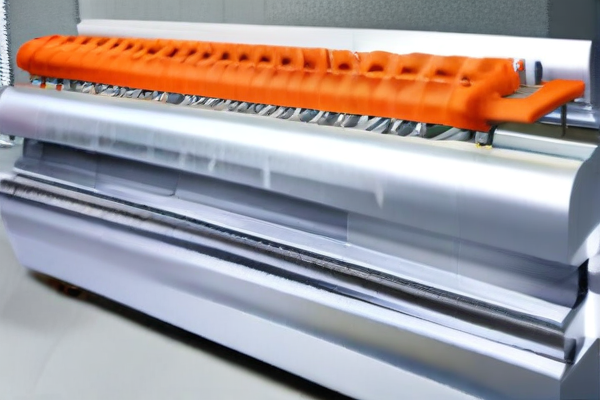

7. Can I customize the flow wrapping machine to fit my needs?

Yes, SourcifyChina factory provides customization options to tailor the machine to your specific requirements. You can discuss your needs with their engineering team to ensure the machine integrates seamlessly into your production line.

8. What is the warranty period for the flow wrapping machine?

The standard warranty period is typically 1 year, covering any manufacturing defects. Extended warranties might be available upon request.

9. What payment methods are accepted?

SourcifyChina factory accepts various payment methods, including wire transfers, letters of credit, and other commonly used international payment systems.

10. How do I place an order?

You can place an order by contacting SourcifyChina factory directly via their website, phone, or email. Their sales team will guide you through the process, from initial inquiry to final purchase.