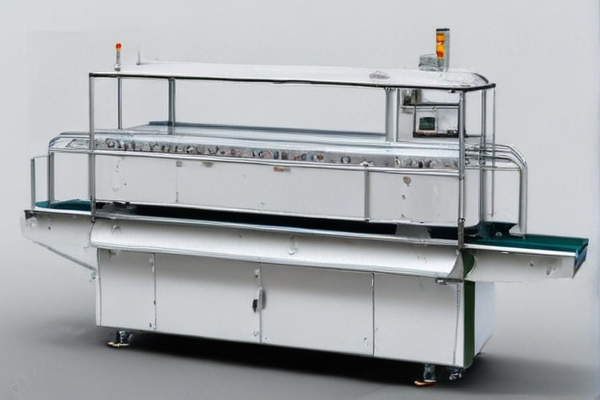

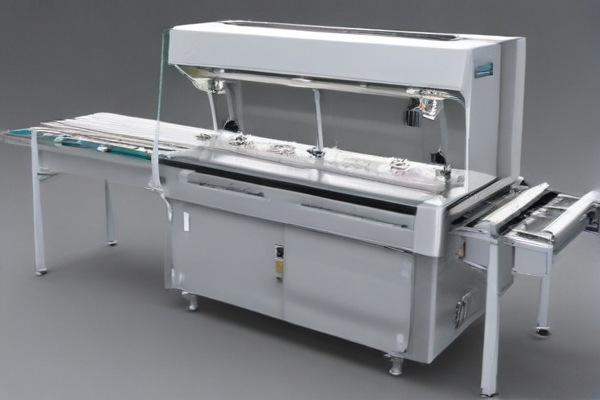

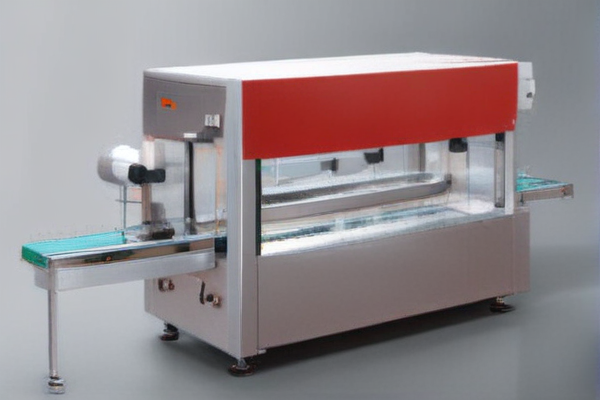

Flow wrapping machines, also known as horizontal form-fill-seal machines, offer versatile and efficient packaging solutions for various products. They ensure product protection, extend shelf life, and provide visually appealing packaging.

– Speed and Efficiency: Capable of high-speed operations, some machines reach up to 300 packs per minute.

– Versatility: Handle a wide range of products such as food items, medical supplies, and consumer goods.

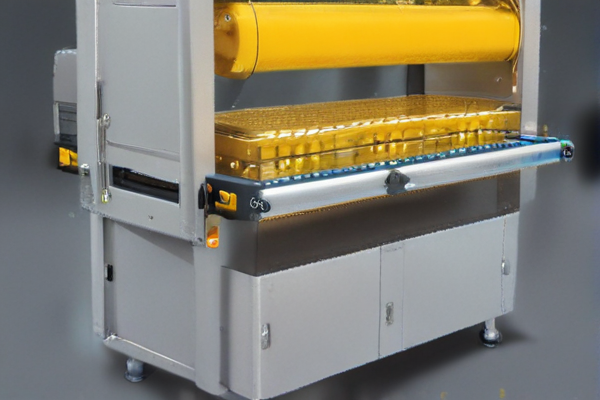

– Automation: Features like automatic feeding, sealing, and cutting minimize manual intervention and labor costs.

– Precision: Advanced sensors and controls ensure consistent and precise packaging.

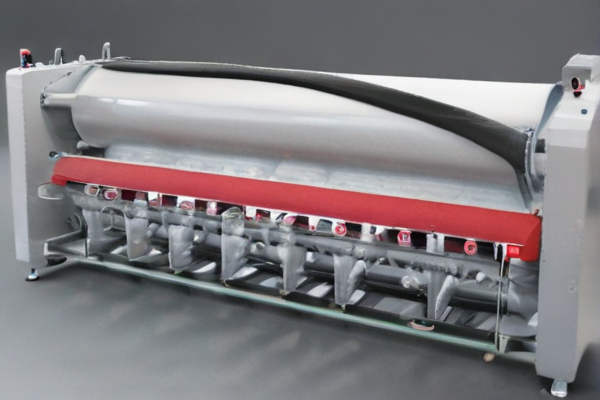

– Material Compatibility: Work with various packaging materials like plastic, aluminum foil, and paper.

– Customization: Adjustable machine settings allow for different product sizes and shapes.

– Product Safety: Hermetic seals protect contents from contamination and environmental factors.

– Minimal Waste: Efficient material usage reduces packaging waste, making them eco-friendly.

– Ease of Use: User-friendly interfaces and touch-screen controls simplify operation and maintenance.

– Durability: Built with high-quality materials and robust engineering for long-term use.

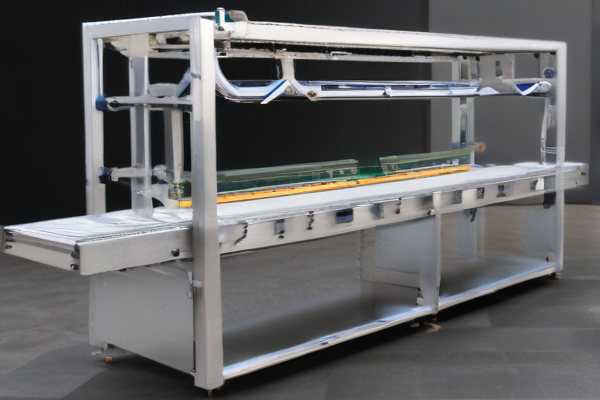

– Compact Design: Occupy minimal floor space, ideal for facilities with space constraints.

– Flexibility: Easily integrate with other machinery and production lines.

– Energy Efficiency: Designed to consume less power, contributing to lower operational costs.

– Compliance: Meet industry standards and regulations, ensuring safety and quality.

Flow wrapping machines are essential for modern packaging needs, offering reliability, efficiency, and versatility across various industries.