Sure, here is a concise FAQ list for manufacturing quality food packaging machines from SourcifyChina factory:

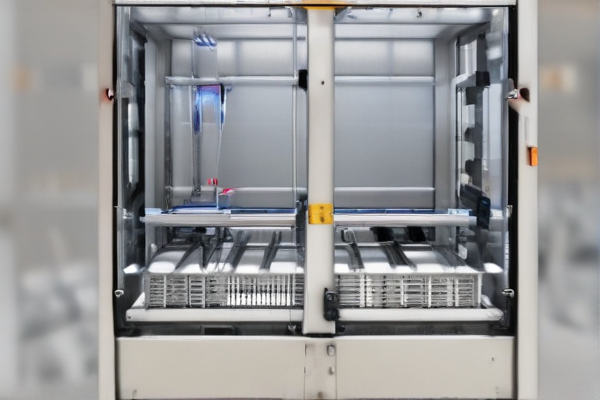

Q1: What types of food packaging machines does SourcifyChina manufacture?

A1: SourcifyChina manufactures a wide variety of food packaging machines including vacuum sealers, flow wrappers, thermoforming machines, and vertical form fill seal machines, catering to different packaging needs.

Q2: How does SourcifyChina ensure the quality of their food packaging machines?

A2: Quality assurance is achieved through stringent quality control processes, including the use of high-grade materials, compliance with international standards, and thorough testing at various stages of manufacturing.

Q3: Are the machines from SourcifyChina customizable?

A3: Yes, SourcifyChina offers customization options to meet the specific requirements of clients, including size adjustments, automation features, and specialized functions.

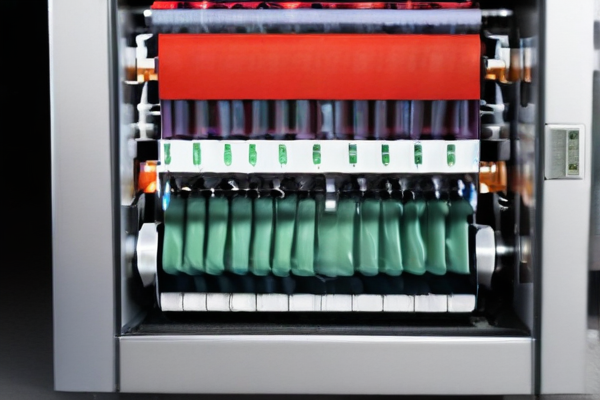

Q4: What types of materials are compatible with SourcifyChina’s packaging machines?

A4: The machines are compatible with a wide range of packaging materials such as plastic films, aluminum foil, paper, and biodegradable materials, ensuring versatility in packaging solutions.

Q5: What is the typical lead time for an order?

A5: The lead time varies depending on the complexity and quantity of the order, but typically ranges from 30 to 60 days from the date of order confirmation.

Q6: Does SourcifyChina provide after-sales support?

A6: Absolutely, SourcifyChina provides comprehensive after-sales support including installation assistance, operational training, maintenance services, and replacement parts supply.

Q7: Are SourcifyChina’s food packaging machines energy efficient?

A7: Yes, the machines are designed to be energy efficient with advanced technology to minimize energy consumption while maximizing productivity.

Q8: Can I request a sample machine before placing a bulk order?

A8: Yes, clients can request sample machines to evaluate the quality and performance before committing to a bulk purchase.

Q9: What is the warranty policy of SourcifyChina for its food packaging machines?

A9: SourcifyChina provides a one-year warranty covering any manufacturing defects. Extended warranty options are also available upon request.

Q10: How can I place an order with SourcifyChina?

A10: Orders can be placed through their website, by contacting their sales team via email or phone, or during industry trade shows where SourcifyChina participates.