Sure, here’s a list of FAQs regarding sourcing food packaging machines from SourcifyChina factory:

1. What types of food packaging machines do you offer?

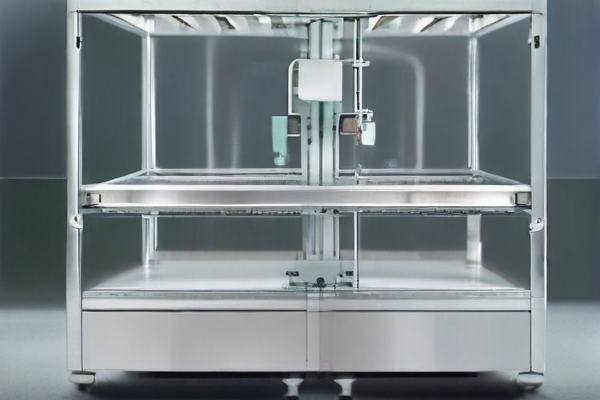

We offer a wide range of food packaging machines including vacuum packaging machines, flow wrapping machines, shrink wrapping machines, tray sealing machines, and more. Each machine caters to different packaging needs and product types.

2. How can I place an order?

To place an order, you can contact our sales team via email or phone. Provide your requirements and specifications, and we will guide you through the process including price quotation, lead times, and payment terms.

3. What are the payment terms?

Our standard payment terms are typically 30% advance payment with the balance due before shipment. However, specific terms can be discussed and agreed upon based on your order volume and other factors.

4. Do you provide after-sales service and support?

Yes, we offer comprehensive after-sales support including installation guidance, troubleshooting, and maintenance. Our technical support team is available to assist you to ensure your machine operates efficiently.

5. What is the lead time for order fulfillment?

The lead time varies depending on the complexity and quantity of the machines ordered. Generally, it takes about 4-6 weeks for standard machines and longer for customized equipment.

6. Can I request a machine demo before purchasing?

Yes, we can arrange for a live demonstration of our machines. You can visit our factory or we can conduct a virtual demo to showcase the machine’s capabilities.

7. Are the machines compliant with international standards?

Absolutely. Our machines are designed and manufactured in compliance with international safety and quality standards, such as CE and ISO certifications.

8. Do you offer customization options?

Yes, we provide customization services to meet specific requirements. Share your detailed needs, and our engineering team can tailor the machine design accordingly.

9. What kind of warranty do you offer?

We offer a standard one-year warranty on all our machines. This covers any manufacturing defects and provides peace of mind regarding the machine’s durability and performance.

10. How do you handle shipping and logistics?

We manage shipping and logistics through reliable freight forwarders. We ensure safe and timely delivery of machines to your designated location, complete with all necessary documentation.