Sure, here’s a list of frequently asked questions (FAQ) along with their answers for sourcing food packaging machinery from SourcifyChina factory:

Q: What types of food packaging machinery does SourcifyChina factory offer?

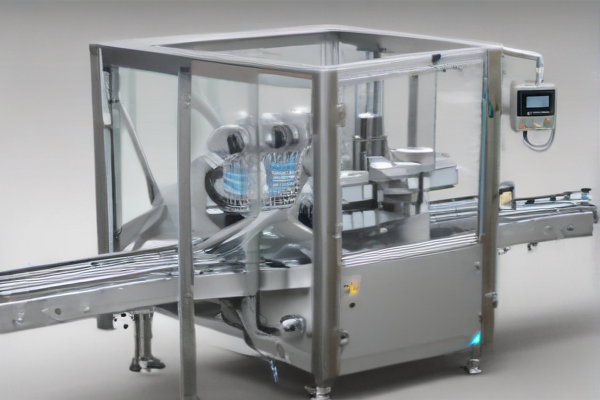

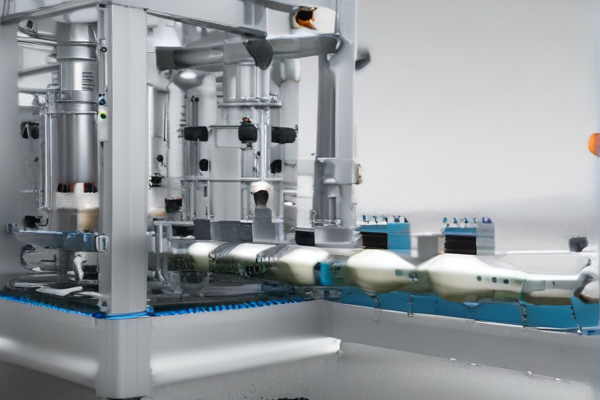

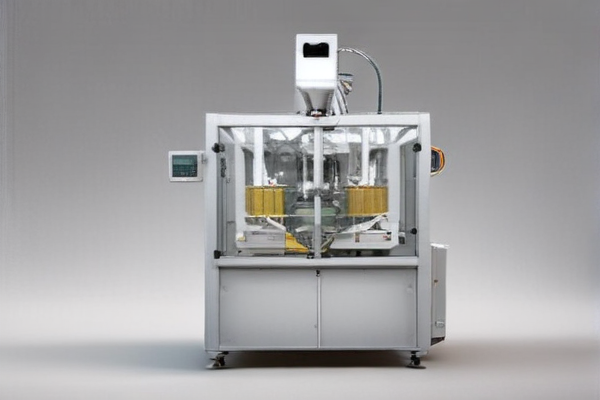

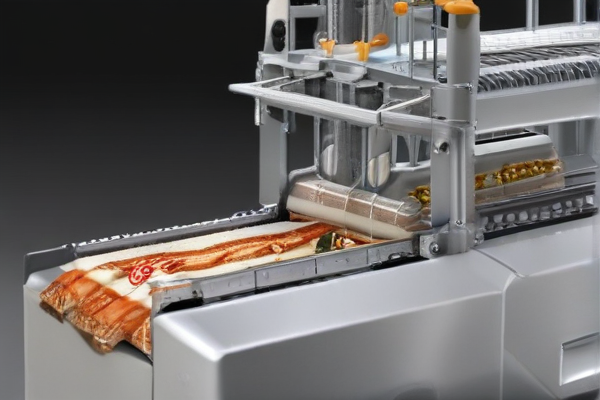

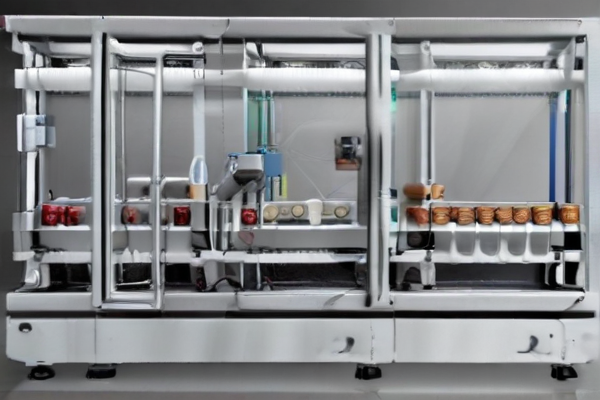

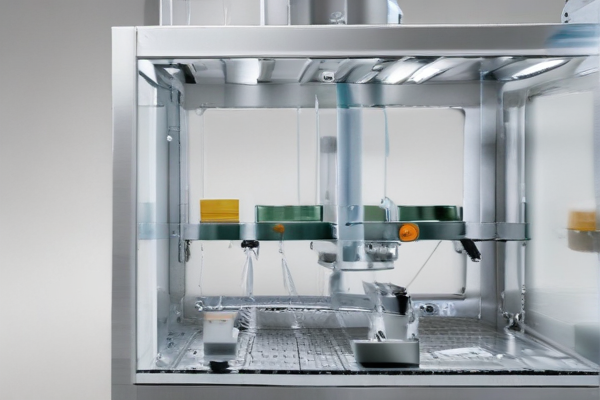

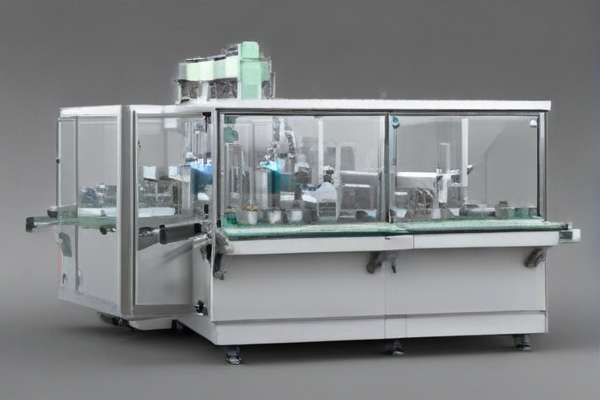

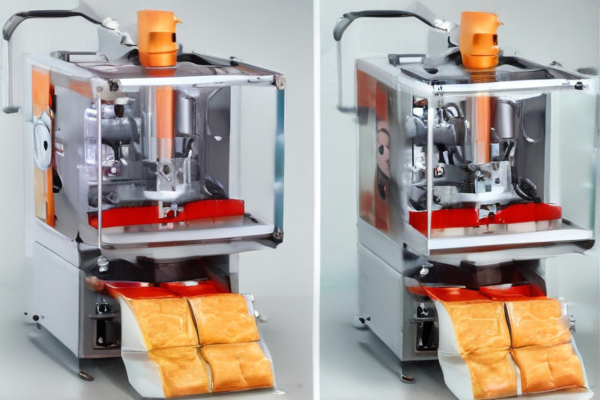

A: SourcifyChina factory offers a range of food packaging machinery, including vacuum packaging machines, sealing machines, filling machines, and automated packaging lines designed for various types of food products.

Q: How can I get a quote for the machinery?

A: You can get a quote by contacting SourcifyChina factory directly through their website or customer service email. Provide details about the machinery you need and your specific requirements for an accurate quote.

Q: What is the lead time for delivery?

A: The lead time varies depending on the type and quantity of machinery ordered. Typically, it ranges from 4 to 8 weeks. For more precise information, please check with their sales team.

Q: Can I customize the machinery according to my needs?

A: Yes, SourcifyChina offers customization options to meet specific requirements. Discuss your needs with their technical team to tailor the machinery to your production process.

Q: Do they offer installation and training services?

A: Yes, SourcifyChina factory provides installation services and training for your staff to ensure the machinery is correctly set up and operated. These services may be included or offered at an additional cost.

Q: What kind of warranty and after-sales support is available?

A: SourcifyChina typically offers a 1-year warranty on their machinery. They also provide after-sales support, including maintenance, spare parts, and technical assistance to ensure smooth operation.

Q: How do I ensure the quality of the machinery?

A: SourcifyChina follows strict quality control procedures. You can request quality certificates, production process videos, or even arrange for third-party inspections to ensure the machinery meets your standards.

Q: What payment methods are accepted?

A: SourcifyChina generally accepts wire transfers (T/T), L/C (Letter of Credit), and sometimes other methods like PayPal depending on the agreement.

Q: Are there any minimum order requirements?

A: Minimum order requirements vary by machine type and customization needs. Consult the sales team for specifics.

Q: Can I visit the factory before placing an order?

A: Yes, SourcifyChina encourages potential customers to visit their factory. This helps you understand their manufacturing capabilities and quality assurance processes.