Sure! Here’s a concise FAQ list for sourcing food packaging machines from SourcifyChina factory:

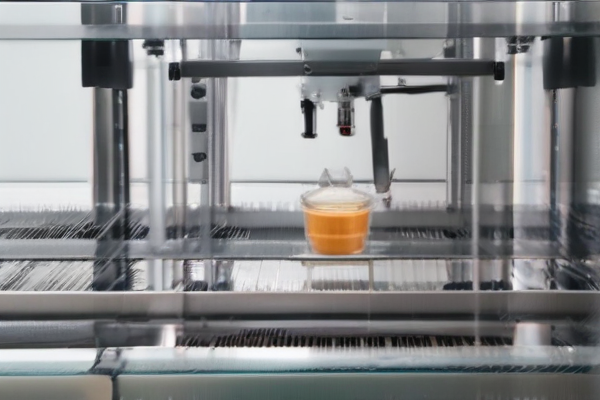

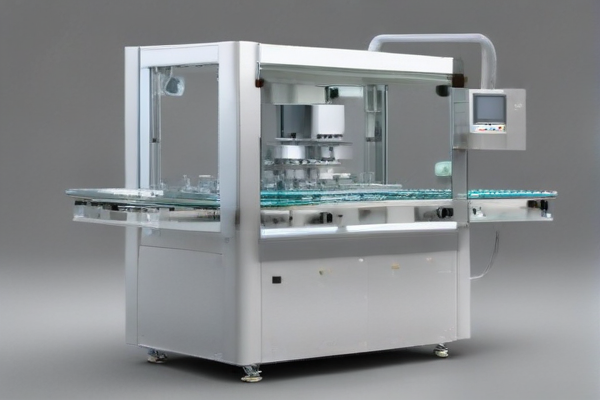

Q: What types of food packaging machines does SourcifyChina offer?

A: SourcifyChina offers a wide range of food packaging machines including vacuum sealers, flow wrappers, tray sealers, form-fill-seal machines, and labeling machines.

Q: How can I get a quote for a food packaging machine?

A: You can get a quote by visiting our website and filling out the inquiry form, emailing us directly, or calling our customer service hotline. Please provide detailed information about your requirements.

Q: What is the lead time for a custom food packaging machine?

A: The lead time typically ranges from 4 to 12 weeks, depending on the complexity and customization needs of your order.

Q: Do you provide installation and training services?

A: Yes, SourcifyChina offers installation and training services either on-site or via virtual sessions. Our technicians ensure that your team understands the machine operation and maintenance.

Q: Are the machines compliant with international standards?

A: Absolutely. All our food packaging machines comply with international standards such as CE, ISO, and FDA regulations to ensure safety and quality.

Q: What warranty do you offer on your food packaging machines?

A: We provide a standard one-year warranty on all our machines, covering parts and labor. Extended warranty options are also available upon request.

Q: Do you have after-sales support?

A: Yes, we have a dedicated after-sales support team available 24/7 to assist with troubleshooting, spare parts, and maintenance services.

Q: Can I visit the SourcifyChina factory to inspect the machines?

A: Yes, we welcome factory visits. Please contact us in advance to schedule an appointment, ensuring our team is available to provide a thorough tour.

Q: What payment methods are accepted?

A: We accept various payment methods including bank transfers (T/T), letters of credit (L/C), and other mutually agreed-upon terms.

Q: Do you offer financing options?

A: Yes, SourcifyChina provides flexible financing options in collaboration with financial institutions to support your purchasing needs.

This guide should help you with common inquiries about sourcing food packaging machines from SourcifyChina.