What is the quality standard of food wrapper machines manufactured by SourcifyChina factory?

The food wrapper machines from SourcifyChina adhere to international standards and are built using high-quality materials to ensure durability and efficiency. Each machine undergoes rigorous quality control checks to meet industry specifications.

Are the food wrapper machines from SourcifyChina factory certified?

Yes, all equipment manufactured by SourcifyChina factory is ISO 9001 certified, ensuring that they meet top-notch quality management system standards.

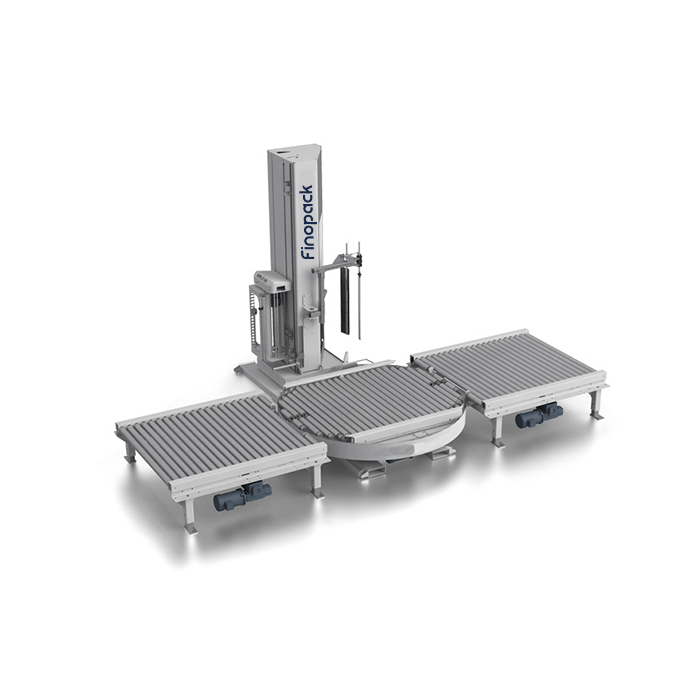

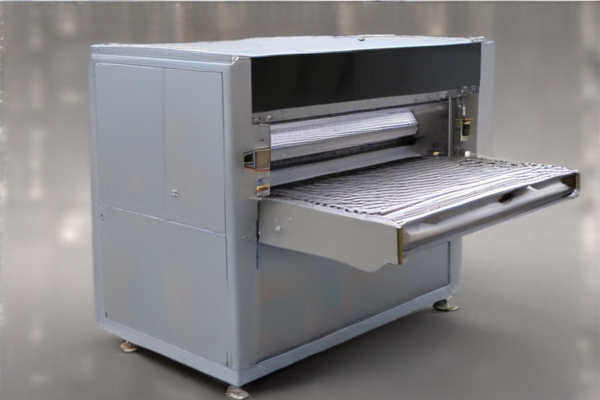

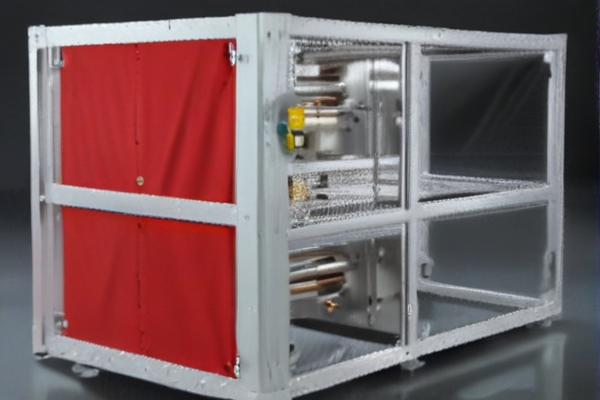

What types of food wrapper machines does SourcifyChina specialize in?

SourcifyChina offers a wide range of food wrapper machines including flow wrappers, vacuum sealers, shrink wrap machines, and tray sealers, suitable for various food packaging needs.

How do I ensure the machines will meet my specific packaging requirements?

We offer customized solutions tailored to your specific packaging requirements. Our team of experts will work with you to understand your needs and provide machines that suit your product specifications.

What kind of technical support and after-sales service does SourcifyChina provide?

SourcifyChina provides comprehensive technical support including installation, training, routine maintenance, and troubleshooting. We also offer a warranty and spare parts for the machines to ensure long-term reliability.

How can I place an order for a food wrapper machine from SourcifyChina factory?

You can place an order by contacting our sales team through our official website or via email. Our representatives will guide you through the entire process, from selecting the right machine to completing the purchase.

What is the typical lead time for the delivery of the food wrapper machines?

The lead time for delivery typically ranges from 4 to 8 weeks, depending on the complexity and customization of the machine ordered.

Are there any client testimonials or case studies available for reference?

Yes, we can provide testimonials and case studies from our satisfied clients. Please contact our sales team to request detailed information.

What payment methods are accepted for purchasing from SourcifyChina?

We accept various payment methods including wire transfer, L/C (Letter of Credit), and Paypal, making the transaction process convenient for our clients.

Can the food wrapper machines be integrated into an existing production line?

Yes, our food wrapper machines are designed to be compatible with various production lines. Our team can assist with integration to ensure seamless operation within your existing setup.