Sure! Here’s a list of frequently asked questions (FAQ) with answers for sourcing a food wrapping machine from SourcifyChina factory:

1. What is the lead time for a food wrapping machine?

The standard lead time for a food wrapping machine is typically 4-6 weeks. However, this may vary based on customization requirements and current order volumes.

2. Can the food wrapping machines be customized?

Yes, SourcifyChina offers customization options for size, functionality, and additional features to meet your specific needs.

3. What is the minimum order quantity (MOQ)?

The MOQ for food wrapping machines is generally one unit. For bulk orders, MOQ discounts may apply.

4. What payment terms do you offer?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal for smaller orders. Specific terms can be discussed during the ordering process.

5. Are there warranties available for the food wrapping machines?

Yes, our food wrapping machines come with a 12-month warranty covering manufacturing defects and technical issues.

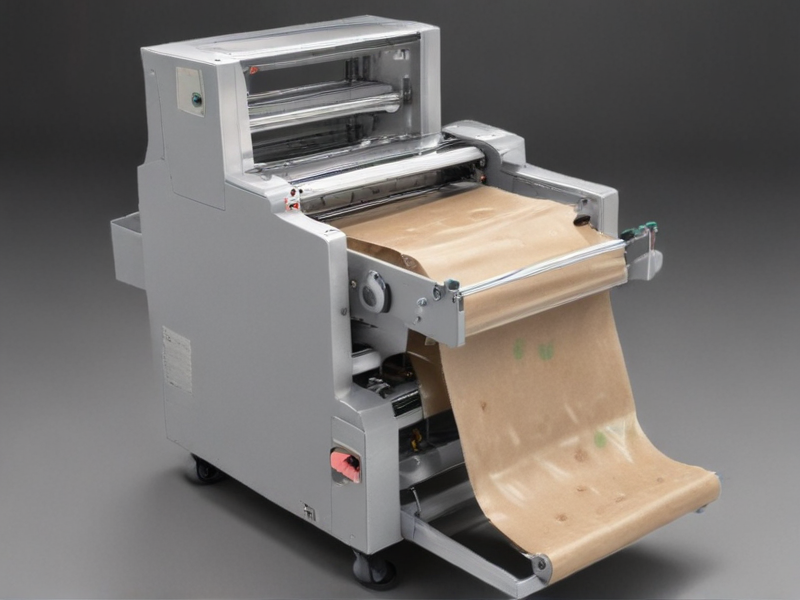

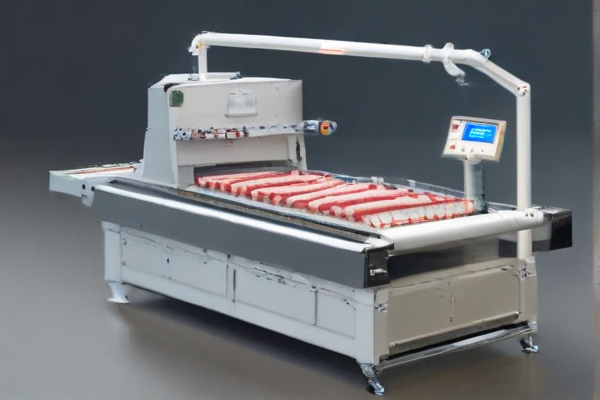

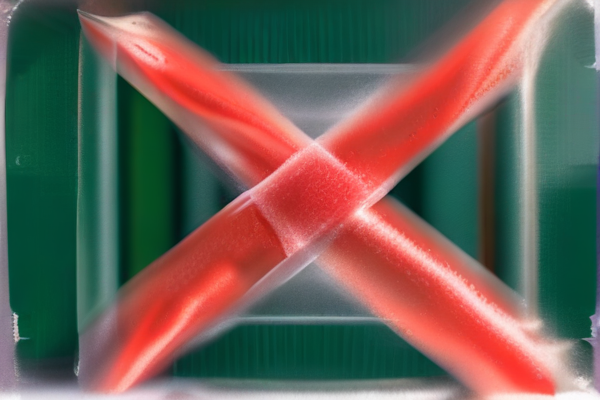

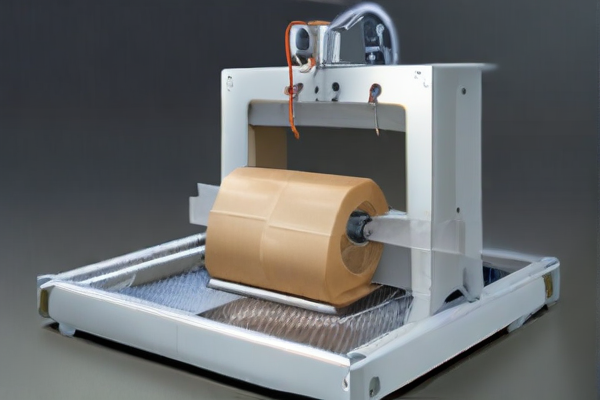

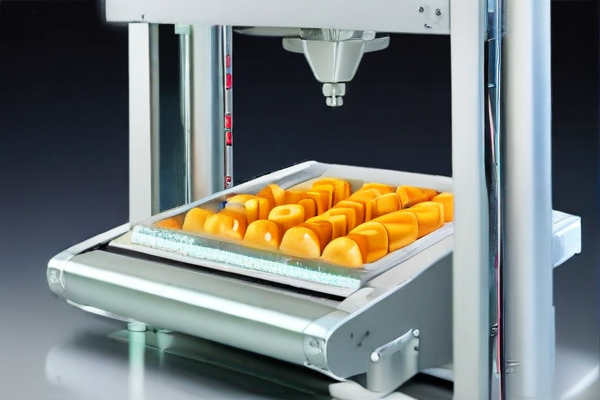

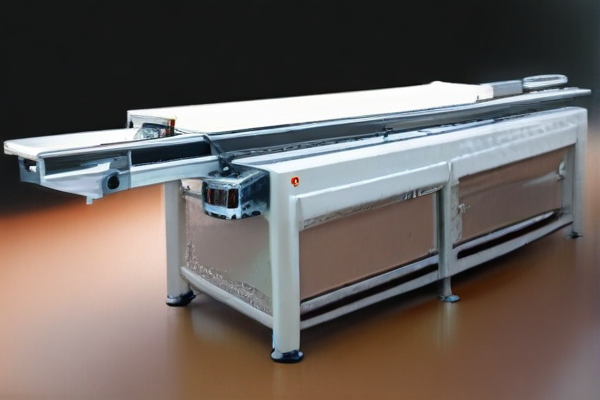

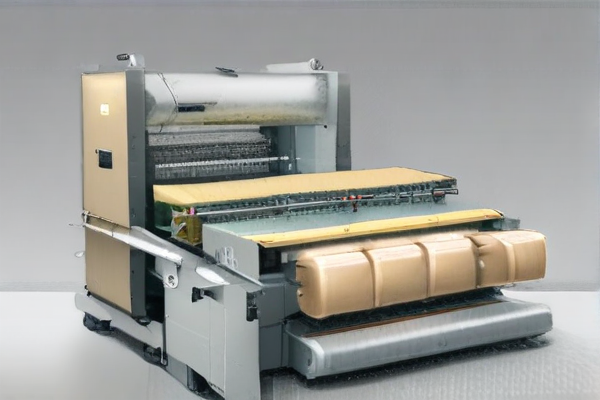

6. What types of food wrapping machines are available?

We offer various types, including manual, semi-automatic, and fully automatic food wrapping machines, suitable for different packaging needs.

7. Do you offer installation and training services?

Yes, SourcifyChina provides installation guidelines and training support. On-site services can be arranged upon request, subject to additional charges.

8. How do you handle shipping and delivery?

Machines are shipped via sea or air freight. We handle all export documentation, and you can choose between FOB (Free On Board) or CIF (Cost, Insurance, and Freight) terms.

9. What is the after-sales service policy?

We offer comprehensive after-sales support, including remote troubleshooting, spare parts supply, and regular maintenance advice.

10. Can I visit SourcifyChina factory before placing an order?

Yes, we welcome factory visits. Please contact us to schedule your visit and we will assist with travel arrangements.