Form fill and seal machines are widely used in the packaging industry to automate the process of forming, filling, and sealing various types of packages. These machines enhance efficiency, reduce labor costs, and ensure consistent product quality.

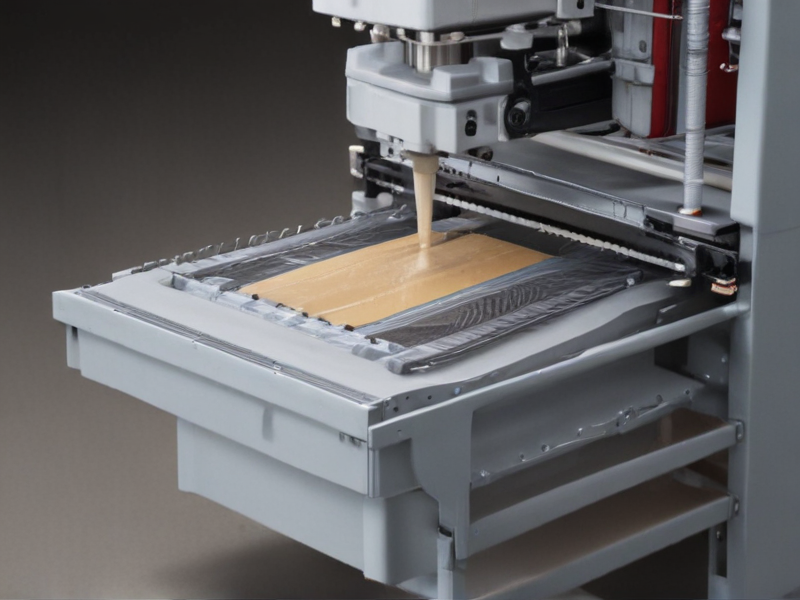

– Food Industry: Packaging snacks, cereals, sauces, and dairy products.

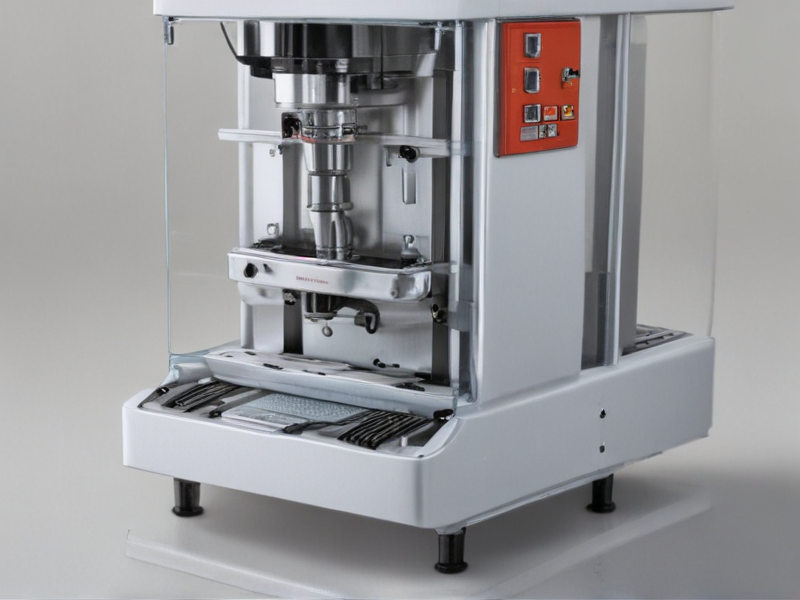

– Pharmaceuticals: Creating sterile packages for medicines, pills, and medical devices.

– Cosmetics: Packing creams, lotions, and beauty products in different containers.

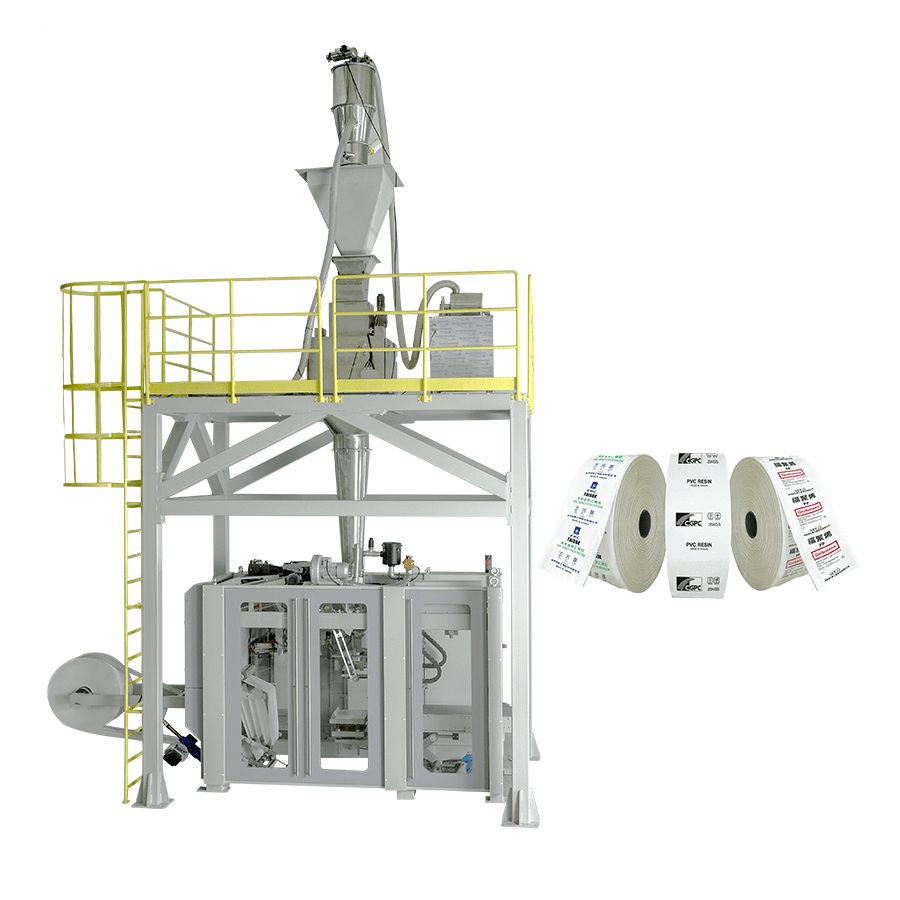

– Chemical Industry: Safely packaging chemicals, fertilizers, and cleaning agents.

– Beverages: Sealing pouches for liquid products like juices, milk, and alcoholic drinks.

– Pet Food: Packaging kibbles, treats, and wet pet food.

– Agricultural Products: Bagging seeds, grains, and other farm-related products.

– Construction Materials: Packaging items like cement, sand, and adhesives.

– Personal Care: Packing sanitary products, hand sanitizers, and hygiene items.

– Electronics: Encasing small electronic components and accessories.

– Retail Products: Packaging goods like toys, stationery, and small household items.

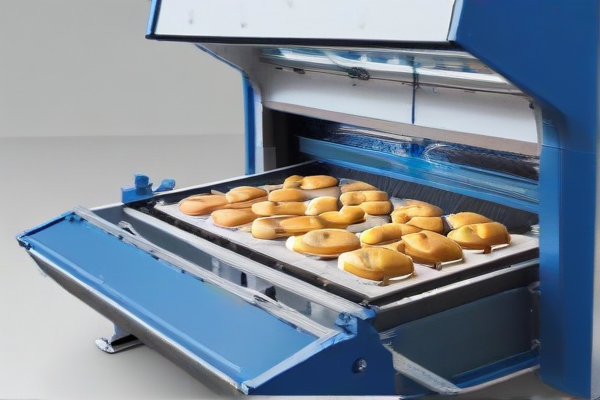

– Bakery Products: Sealing bread, pastries, and other baked items.

– Frozen Foods: Packaging vegetables, fruits, and ready-to-eat meals.

– Meat and Seafood: Ensuring vacuum-sealed packaging for fresher products.

– Petroleum Products: Encasing lubricants, oils, and other related products.

– Medical Supplies: Sterile packaging for bandages, gloves, and surgical tools.

– Nutritional Products: Packaging protein powders, supplements, and health snacks.

– Household Items: Packing small tools, nails, and screws.

– Textiles: Packaging small fabrics, trims, and accessories.

– Tobacco: Sealing cigarettes, cigars, and loose tobacco.