Gutkha packing machines come in various types, each designed to meet specific packaging needs. They ensure precise measurement, filling, and sealing. Options include manual, semi-automatic, and fully automatic machines, catering to different production scales.

– Manual Gutkha Packing Machines:

– Operated by hand, suitable for small-scale production.

– Affordable and easy to maintain.

– Ideal for startups and limited budgets.

– Semi-Automatic Gutkha Packing Machines:

– Combines manual and automated features.

– Requires minimal operator involvement.

– Suitable for medium-sized businesses.

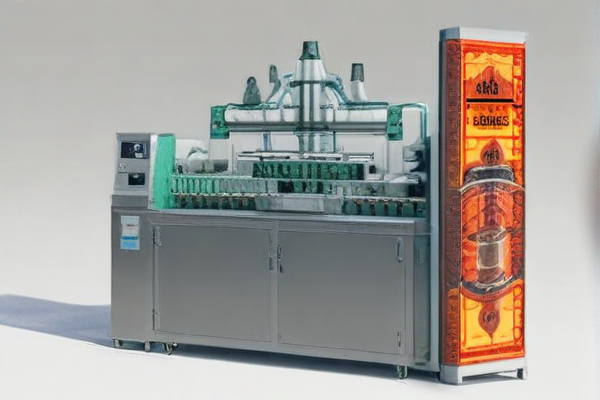

– Fully Automatic Gutkha Packing Machines:

– Fully automated, offering high-speed packaging.

– Ensures consistency and reduces human error.

– Best for large-scale production.

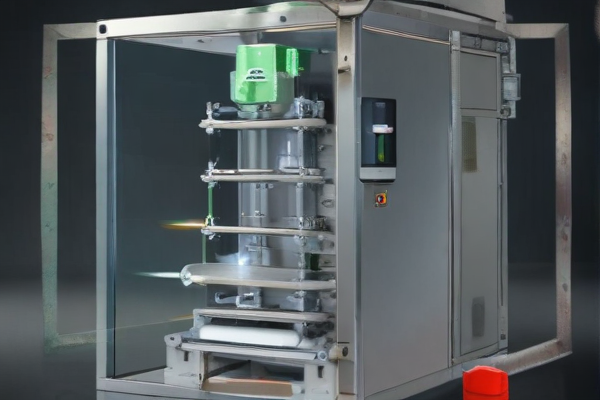

– Form Fill Seal (FFS) Machines:

– Forms the packaging material, fills, and seals it.

– Available in vertical (VFFS) and horizontal (HFFS) types.

– Versatile, handling different pack sizes and shapes.

– Single Track vs. Multi-Track Machines:

– Single Track: Packs one item at a time, used for lesser volumes.

– Multi-Track: Multiple items simultaneously, ideal for high-volume requirements.

– Features to Consider:

– Material Compatibility: Machines should handle the specific type of gutkha material.

– Speed & Efficiency: Higher speeds for large outputs; adjustable for varied production rates.

– Customizable Options: Features like nitrogen flushing, batch coding.

– Maintenance & Support: Availability of spare parts and technical support.

– Safety Features: Ensure compliance with industry standards for operator safety.

Choosing the right gutkha packing machine depends on your business scale, budget, and specific requirements. Each type and option brings its benefits tailored to meet diverse demand scenarios.