Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing a handling system from SourcifyChina factory:

1. What does SourcifyChina factory specialize in?

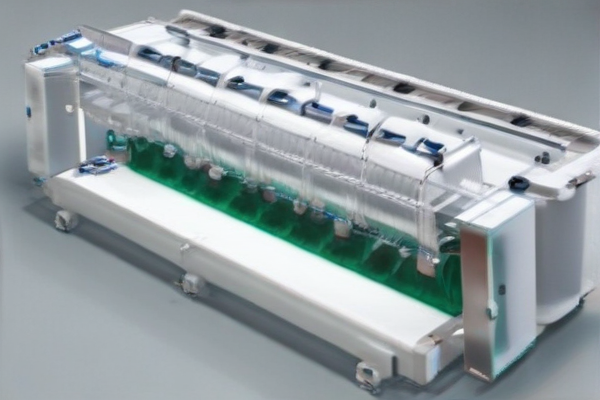

SourcifyChina specializes in manufacturing a wide range of industrial handling systems, including conveyor belts, automated sorting systems, robotic arms, and custom material handling solutions tailored to meet specific operational needs.

2. How can I request a quote for a handling system?

To request a quote, you can visit the SourcifyChina website and fill out the inquiry form with your requirements or contact their sales team directly via email or phone. Provide detailed information about your project to receive an accurate quote.

3. What information is needed to provide an accurate quote?

Key information includes the type of handling system required, specifications (capacity, dimensions, materials), application details, project timeline, and any special requirements or constraints.

4. Can SourcifyChina customize handling systems?

Yes, SourcifyChina offers customization services to meet specific client needs. They work closely with clients to design and manufacture handling systems that match exact specifications and operational requirements.

5. What are the payment terms?

Payment terms typically involve a partial advance payment upon order confirmation, with the remaining balance due before shipment. Specific terms may vary and can be discussed with the sales team.

6. How long does it take to deliver a handling system?

Delivery times vary based on the complexity of the system and current production schedules. On average, standard systems may take 4-8 weeks, while customized solutions could take longer. Confirm the timeline with SourcifyChina during the quote process.

7. Do they provide installation and after-sales support?

Yes, SourcifyChina offers installation services and comprehensive after-sales support, including maintenance, troubleshooting, and spare parts supply. This ensures optimal performance and longevity of the handling systems.

8. Are the handling systems compliant with international standards?

SourcifyChina ensures that all handling systems comply with relevant international standards and regulations, ensuring safety, reliability, and efficiency in various industrial applications.

9. What if there are issues with the system post-delivery?

In case of any issues post-delivery, SourcifyChina provides prompt support through their technical service team. They offer solutions like remote troubleshooting, on-site visits, and warranty services to resolve any problems effectively.

10. How can I ensure quality when sourcing from SourcifyChina?