Sure! Here is a list of FAQs along with answers for manufacturing “hardware packaging machine quality work from SourcifyChina factory”:

Q1: What types of hardware packaging machines does SourcifyChina manufacture?

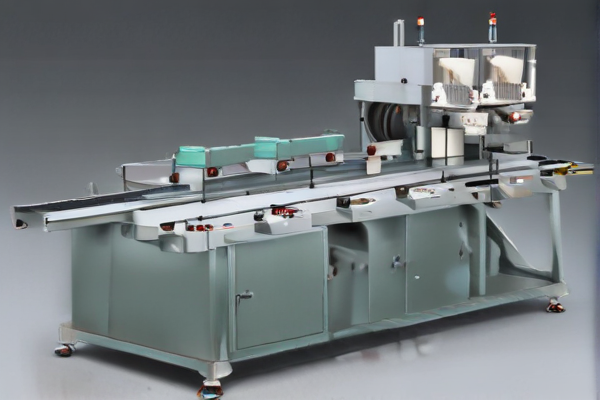

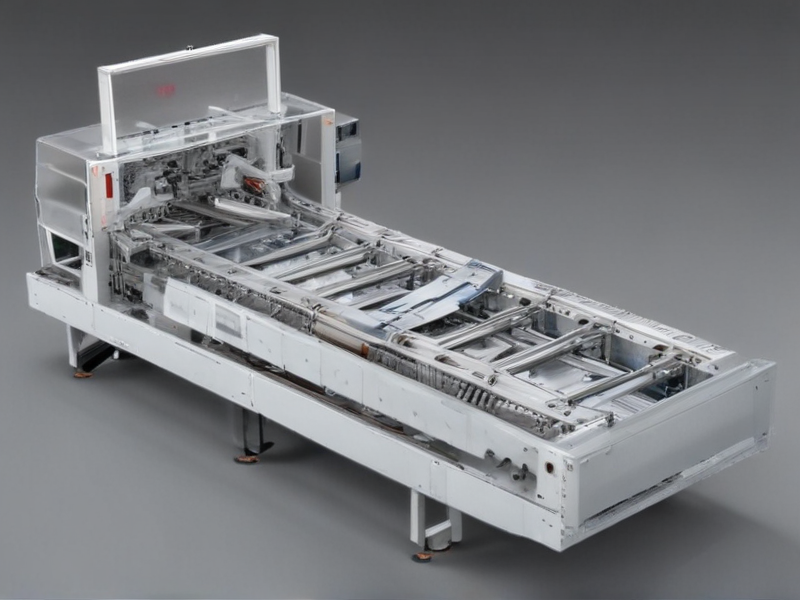

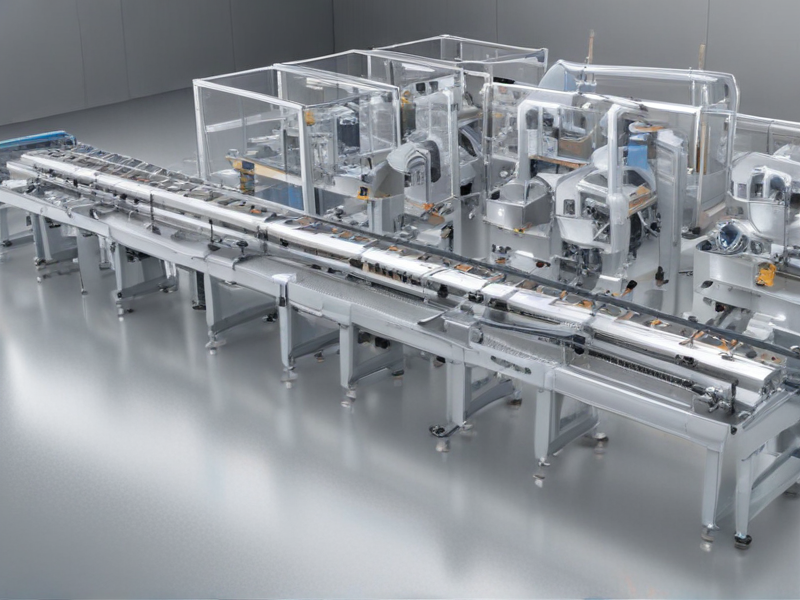

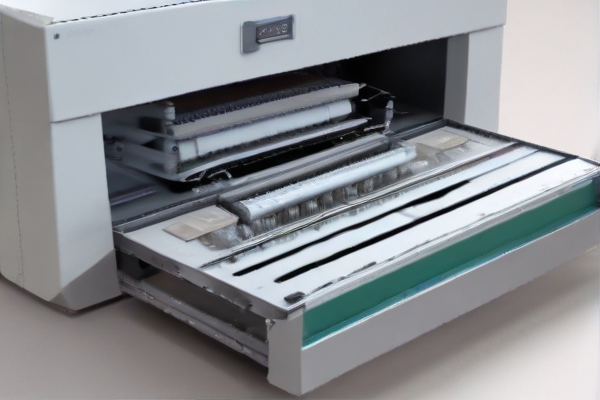

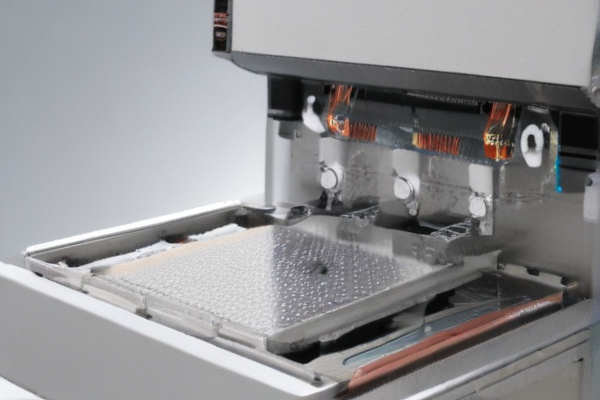

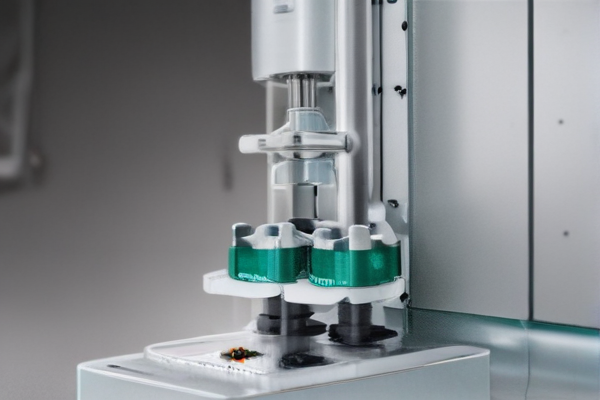

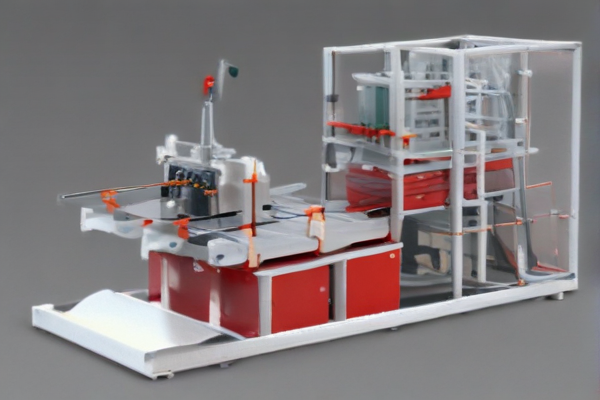

A1: SourcifyChina specializes in manufacturing various types of hardware packaging machines including automatic packing machines, flow wrapping machines, blister packaging machines, and more, customized to meet diverse industry needs.

Q2: How does SourcifyChina ensure the quality of their hardware packaging machines?

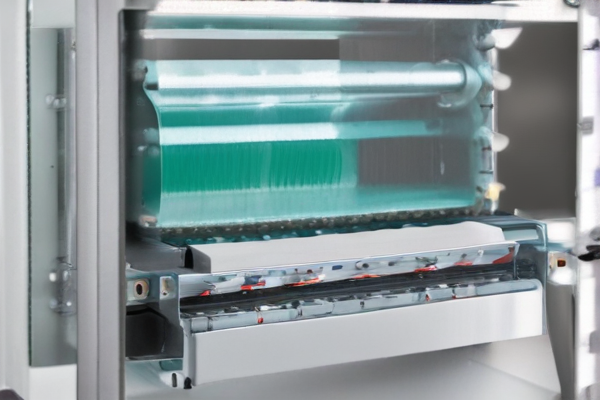

A2: SourcifyChina ensures high-quality standards through rigorous in-house testing, adherence to international manufacturing standards, and the use of premium-grade raw materials and components. Each machine undergoes multiple quality checks before shipment.

Q3: Can SourcifyChina provide customized packaging solutions?

A3: Yes, SourcifyChina offers customized packaging solutions tailored to specific requirements. They work closely with clients to design and manufacture machines that fulfill unique packaging needs.

Q4: What is the typical lead time for a hardware packaging machine from SourcifyChina?

A4: The lead time can vary based on machine complexity and customization requirements. Typically, it ranges from 4 to 8 weeks. Specific timelines are provided during the order confirmation process.

Q5: What kind of after-sales support does SourcifyChina offer?

A5: SourcifyChina provides comprehensive after-sales support including installation assistance, training for operators, regular maintenance services, and a warranty period to ensure seamless operation of the machines.

Q6: Are the machines from SourcifyChina user-friendly and easy to operate?

A6: Yes, SourcifyChina designs user-friendly machines equipped with intuitive controls and detailed operation manuals. Training sessions are also available to help operators become proficient quickly.

Q7: What kind of warranty and maintenance services are offered?

A7: SourcifyChina offers a standard warranty period of one year for major components. They also provide preventive maintenance services and quick response teams for any technical issues.

Q8: How do I place an order with SourcifyChina?

A8: Orders can be placed by contacting SourcifyChina through their website or directly speaking with their sales representatives. They assist with selecting the right machine and provide a detailed quotation.

These FAQs aim to provide a clear and concise understanding of SourcifyChina’s hardware packaging machine offerings and their commitment to quality and customer satisfaction.