Sure! Here is a list of frequently asked questions (FAQ) with answers concerning the quality of horizontal flow wrap machines manufactured by SourcifyChina factory:

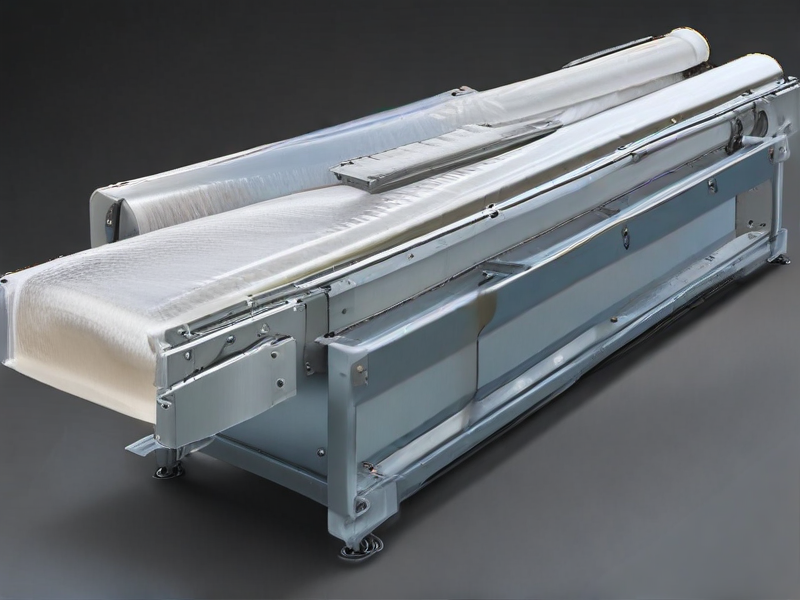

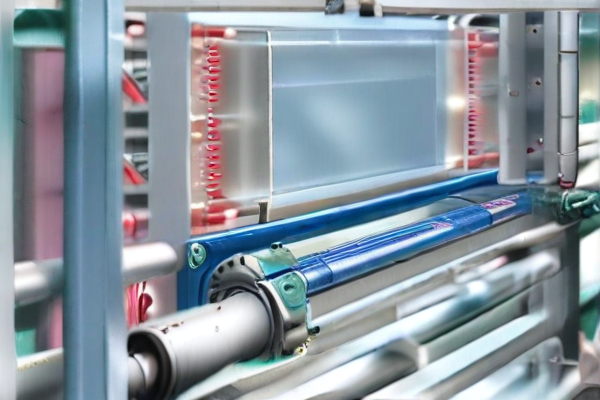

1. What materials are used in the construction of SourcifyChina’s horizontal flow wrap machines?

The construction of our horizontal flow wrap machines involves high-quality stainless steel and aluminum alloys to ensure durability, hygiene, and resistance to corrosion. Components are sourced from reputable suppliers to maintain the highest standard of quality.

2. Are SourcifyChina’s horizontal flow wrap machines compliant with international standards?

Yes, our machines are designed and manufactured according to international standards such as ISO, CE, and GMP to ensure quality and safety. We also adhere to specific customer requirements and regional regulations.

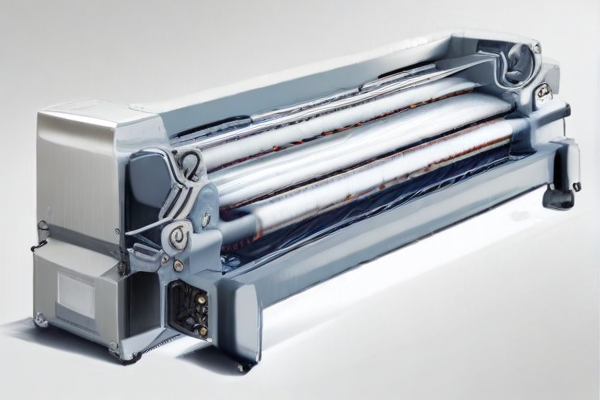

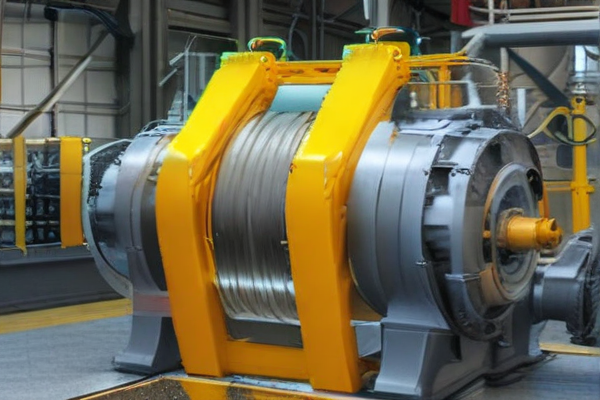

3. What kind of quality control measures does SourcifyChina implement?

SourcifyChina employs a rigorous quality control system that includes multiple stages of inspection, from raw materials to the final product. Each machine undergoes a series of tests to verify its performance, durability, and compliance with specifications.

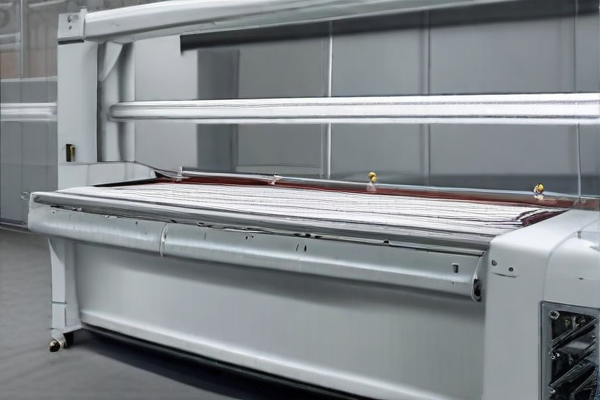

4. How efficient are SourcifyChina’s horizontal flow wrap machines in terms of production speed and accuracy?

Our machines are designed to operate at high speeds with precision, ensuring efficient packaging without sacrificing accuracy. Standard models can wrap up to 300 items per minute, suitable for various production needs.

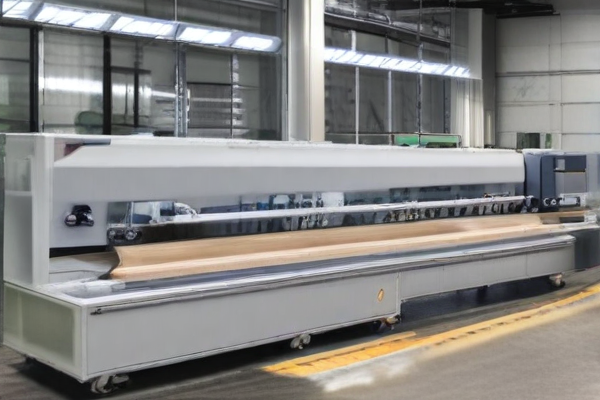

5. Does SourcifyChina offer customization options for their flow wrap machines?

Yes, we offer customization to meet specific requirements, including machine size, wrapping material compatibility, and additional features like automated product feeding and labeling systems.

6. What kind of after-sales support and warranty does SourcifyChina provide?

SourcifyChina offers comprehensive after-sales support, including installation, training, and maintenance services. We provide a standard 12-month warranty for our machines, with extended warranties available upon request.

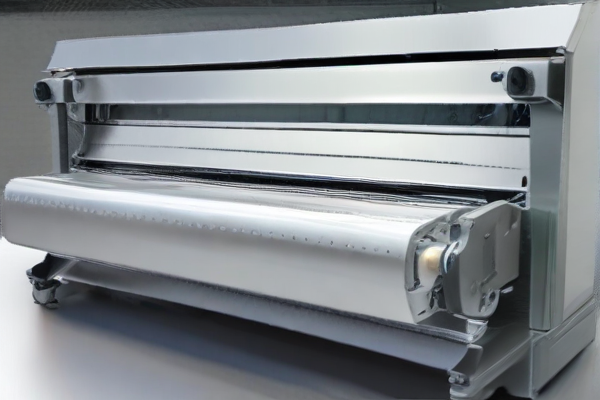

7. Can SourcifyChina’s flow wrap machines handle different types of products?

Yes, our machines are versatile and can wrap various products, including food items, pharmaceuticals, cosmetics, and hardware, thanks to adjustable settings and multiple wrapping formats.

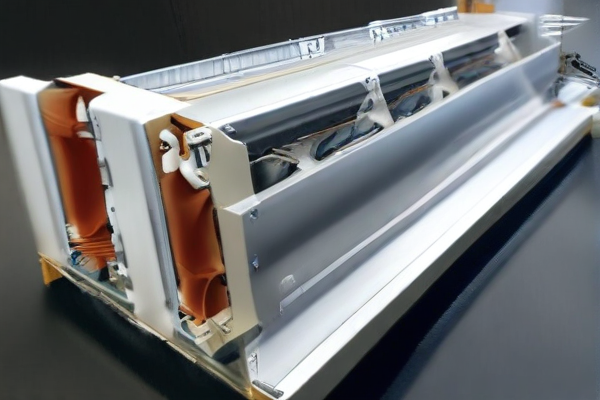

8. How easy is it to operate and maintain SourcifyChina’s flow wrap machines?

Our machines are user-friendly, featuring intuitive interfaces and easy-to-change parts. Regular maintenance is minimal and straightforward, supported by our detailed documentation and technical assistance.

If you have further questions or require additional information, please feel free to contact us.