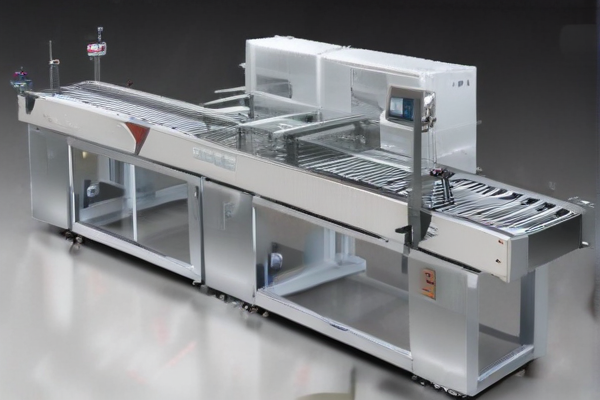

Sure, here’s a list of frequently asked questions (FAQ) with answers regarding sourcing a horizontal flow wrapping machine from SourcifyChina factory:

1. What is the minimum order quantity (MOQ) for a horizontal flow wrapping machine?

Typically, the MOQ for a horizontal flow wrapping machine from SourcifyChina is one unit. However, for customized specifications, the MOQ might vary. Confirm with the sales team.

2. What are the lead times for manufacturing and shipping?

Standard lead times range from 4 to 8 weeks depending on the machine specifications and current production schedule. Shipping times depend on the destination and shipping method.

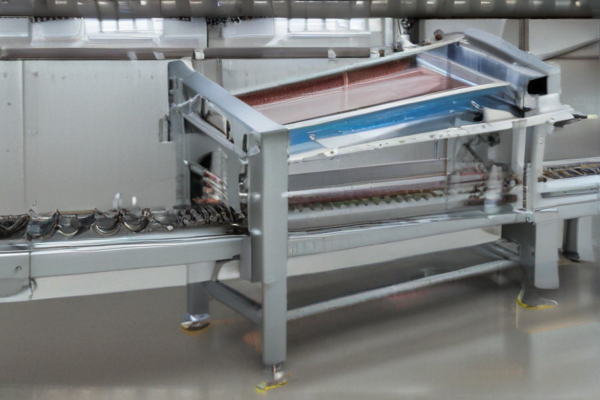

3. Can the horizontal flow wrapping machine be customized?

Yes, SourcifyChina offers customization options for machine size, speed, material, and additional features to meet specific needs.

4. What is the payment process?

Payment terms typically include a 30% deposit upfront, with the remaining 70% due before shipment. Other payment methods can be discussed.

5. Are there any warranties or guarantees for the machine?

Yes, SourcifyChina provides a standard warranty of 12 months on parts and labor, starting from the date of installation.

6. What kind of packaging materials can the machine handle?

The horizontal flow wrapping machine can handle various materials including polyolefin, polypropylene, aluminum foil, and paper.

7. How do I ensure that the machine will meet my specific packaging needs?

Provide detailed specifications and sample materials to SourcifyChina. They will conduct tests to ensure compatibility and performance.

8. Is installation and training included?

Installation and training services are available, which can be done either on-site or remotely, depending on your location and needs.

9. What kind of technical support is available?

SourcifyChina offers continuous technical support via email, phone, and video calls. On-site support can also be arranged if necessary.

10. Can I get a factory tour before making a purchase?

Yes, factory tours can be arranged upon request to inspect the production facilities and discuss specific requirements directly.

If you have any more specific questions, it’s best to contact SourcifyChina directly for detailed and personalized responses.