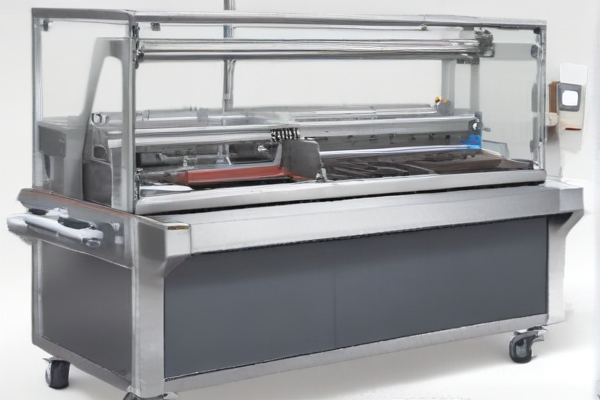

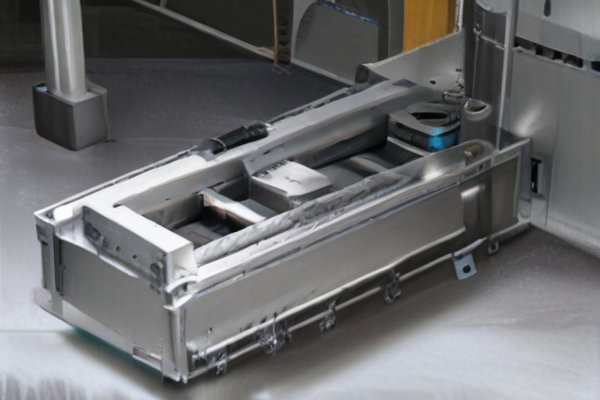

Q: What is a horizontal form fill and seal machine?

A: A horizontal form fill and seal (HFFS) machine is an automated packaging equipment that forms, fills, and seals products in a horizontal position, commonly used for packaging food items, pharmaceuticals, and various other products.

Q: Why should I source an HFFS machine from SourcifyChina factory?

A: SourcifyChina factory is known for offering high-quality HFFS machines at competitive prices with excellent customer support, reliability, and customization options tailored to your specific needs.

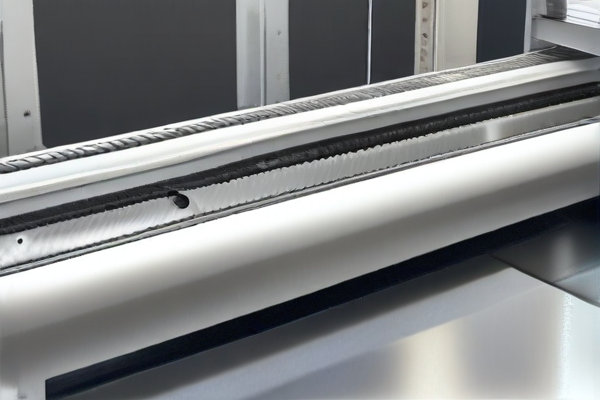

Q: What materials can the HFFS machine handle?

A: The HFFS machine from SourcifyChina can handle a variety of materials including plastics, laminates, foil, and paper-based materials, enabling versatile packaging solutions.

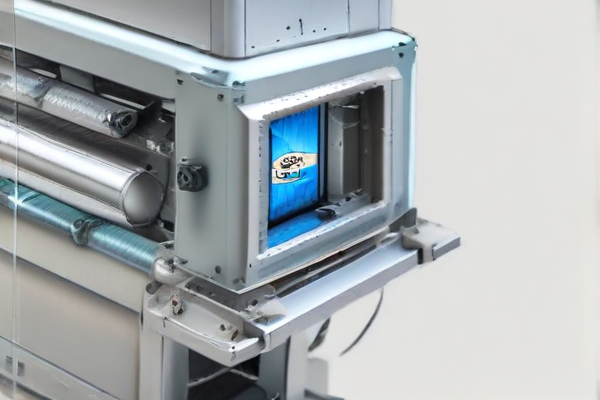

Q: Can the machine be customized according to our product requirements?

A: Yes, SourcifyChina offers customization options to tailor the HFFS machine to meet specific product needs, such as varying sizes, shapes, and packaging materials.

Q: What is the lead time for delivery?

A: The typical lead time for delivery from SourcifyChina factory is between 4 to 8 weeks, depending on the level of customization and current production schedules.

Q: Is there a minimum order quantity (MOQ) for sourcing from SourcifyChina?

A: SourcifyChina does have a minimum order quantity, which varies based on the machine specifications and customization requirements. It’s best to contact them directly for detailed information.

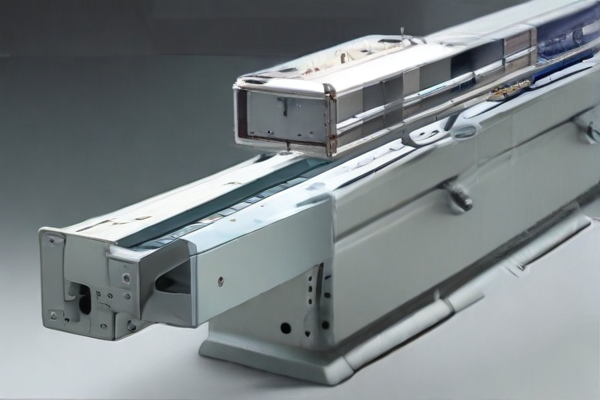

Q: What kind of after-sales support is provided?

A: SourcifyChina provides comprehensive after-sales support, including installation guidance, troubleshooting, maintenance services, and access to spare parts to ensure seamless operation of your HFFS machine.

Q: Are there warranties offered for the HFFS machines?

A: Yes, SourcifyChina offers warranties for their HFFS machines, typically covering parts and labor for a specified period. It’s important to discuss specific warranty terms with them during the purchase process.

Q: How can I ensure the quality of the machine before purchase?

A: SourcifyChina can provide quality assurance documentation, product certifications, and customer testimonials. Additionally, customers are encouraged to request a factory tour or live video inspection.

Q: How do I place an order with SourcifyChina?