Sure, here is a concise FAQ for sourcing horizontal form fill and seal machines from SourcifyChina factory:

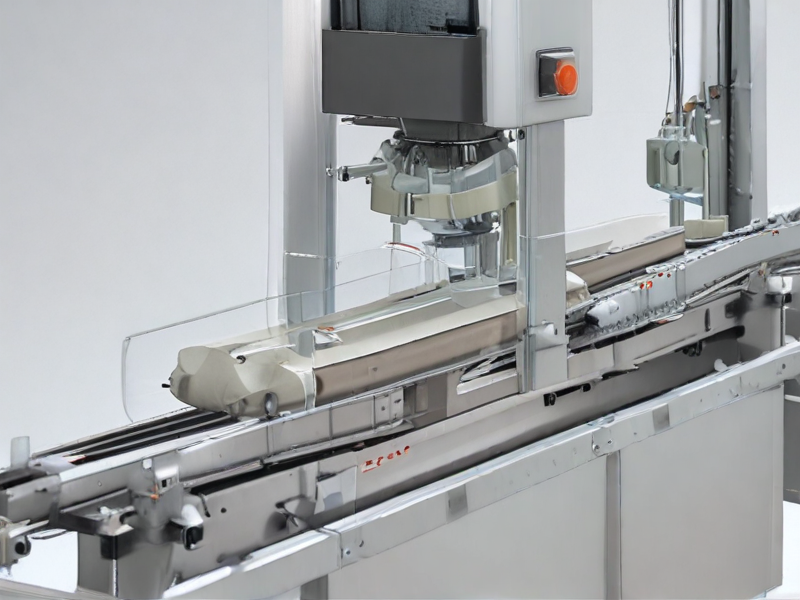

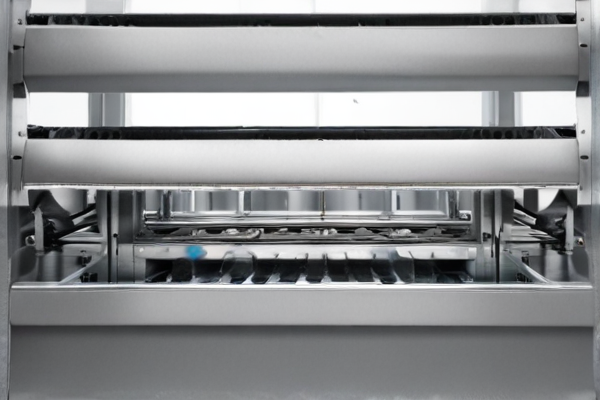

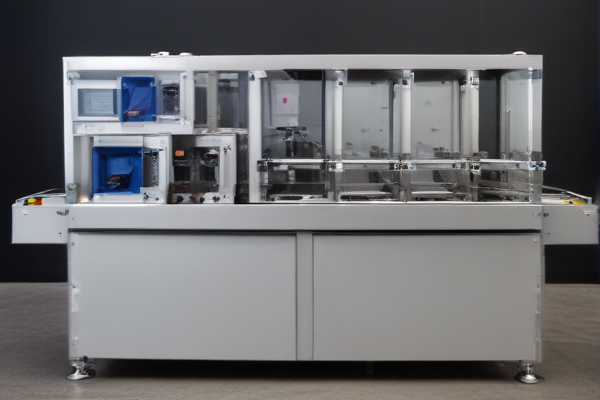

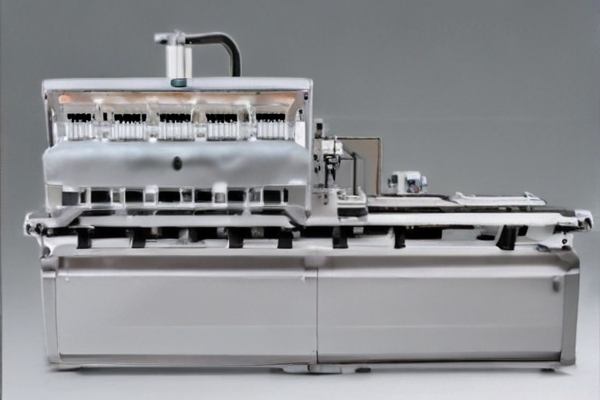

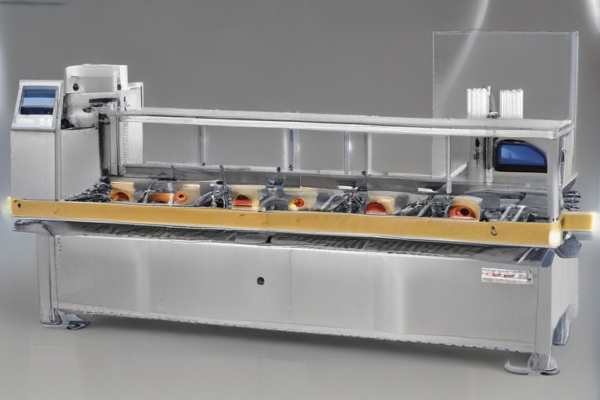

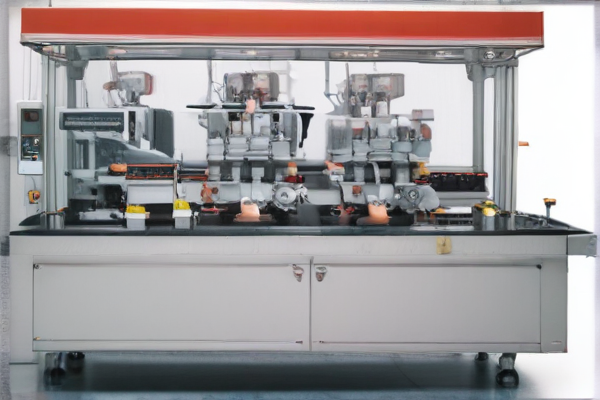

Q1: What types of horizontal form fill and seal machines does SourcifyChina offer?

A1: SourcifyChina provides a wide range of horizontal form fill and seal machines, including models suitable for packaging various food products, pharmaceuticals, and industrial items. Machines differ in terms of speed, film type compatibility, and automation level.

Q2: Are the machines customizable to specific packaging needs?

A2: Yes, SourcifyChina offers customizable solutions to meet your specific packaging requirements. You can specify the type of product, packaging material, and desired output for a tailored solution.

Q3: What is the lead time for delivery?

A3: Typically, the lead time ranges from 4 to 8 weeks, depending on customization requirements and order quantity. For precise information, it is best to contact a SourcifyChina representative.

Q4: Do the machines come with a warranty?

A4: Yes, the machines typically come with a standard 12-month warranty, covering parts and labor. Extended warranties may also be available upon request.

Q5: How can I get a quote?

A5: To get a quote, you can contact SourcifyChina directly through their website’s inquiry form, provide detailed information about your needs, and a representative will get back to you with a customized quote.

Q6: What after-sales support does SourcifyChina provide?

A6: SourcifyChina provides comprehensive after-sales support, including installation assistance, training, and maintenance services. They also offer a range of spare parts and technical support to ensure continuous operation.

Q7: What are the payment terms?

A7: Payment terms generally include a 30% deposit upon order confirmation and the remaining 70% prior to shipment. However, terms may be negotiable based on the client’s requirements and order volume.

Q8: Are there any certifications for the machines?

A8: Yes, SourcifyChina’s machines comply with international standards and come with necessary certifications such as CE, ISO, ensuring reliability and safety.

By addressing these common questions, businesses can ensure a smooth and efficient acquisition of horizontal form fill and seal machines from SourcifyChina.