Here are some frequently asked questions (FAQ) along with answers for manufacturing “induction sealing machine quality work from SourcifyChina factory”:

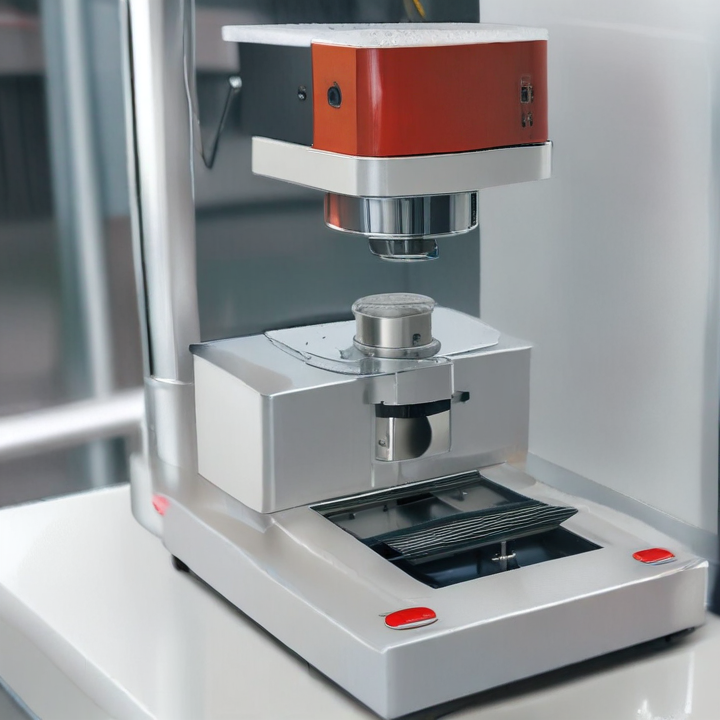

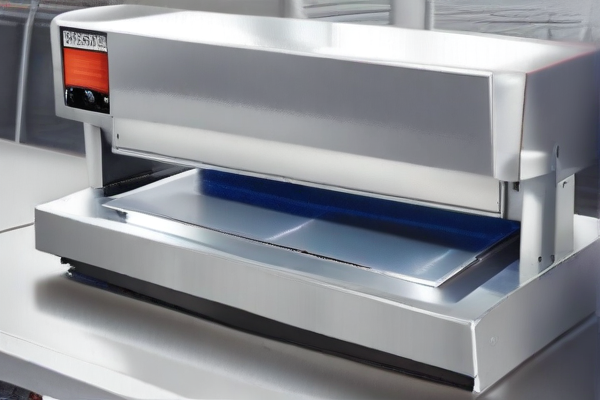

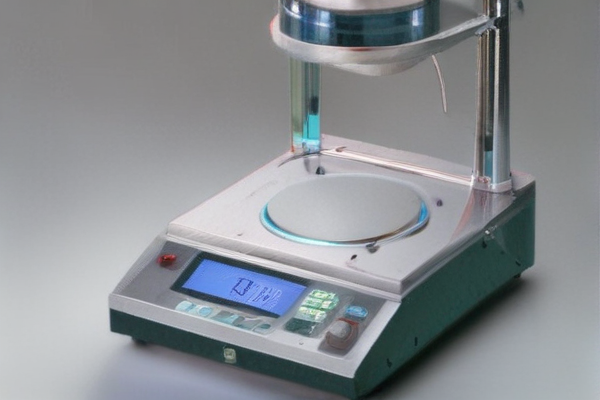

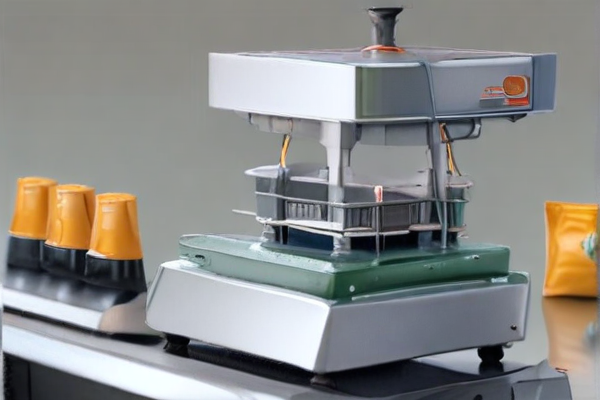

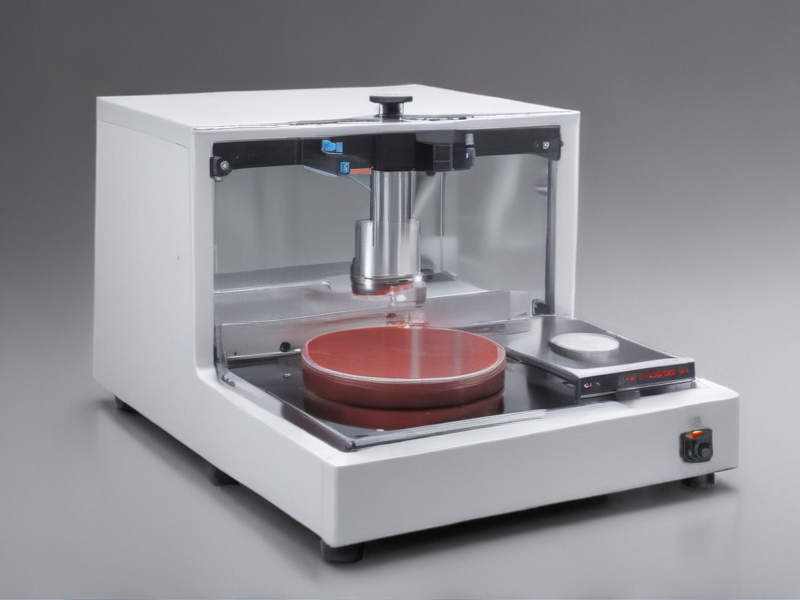

Q1: What types of induction sealing machines do you manufacture?

A1: SourcifyChina factory manufactures a variety of induction sealing machines including manual, semi-automatic, and fully automatic models to cater to different production scales and applications.

Q2: What quality standards do your machines adhere to?

A2: Our induction sealing machines comply with international quality standards such as ISO 9001, CE, and FDA, ensuring reliable and safe operation.

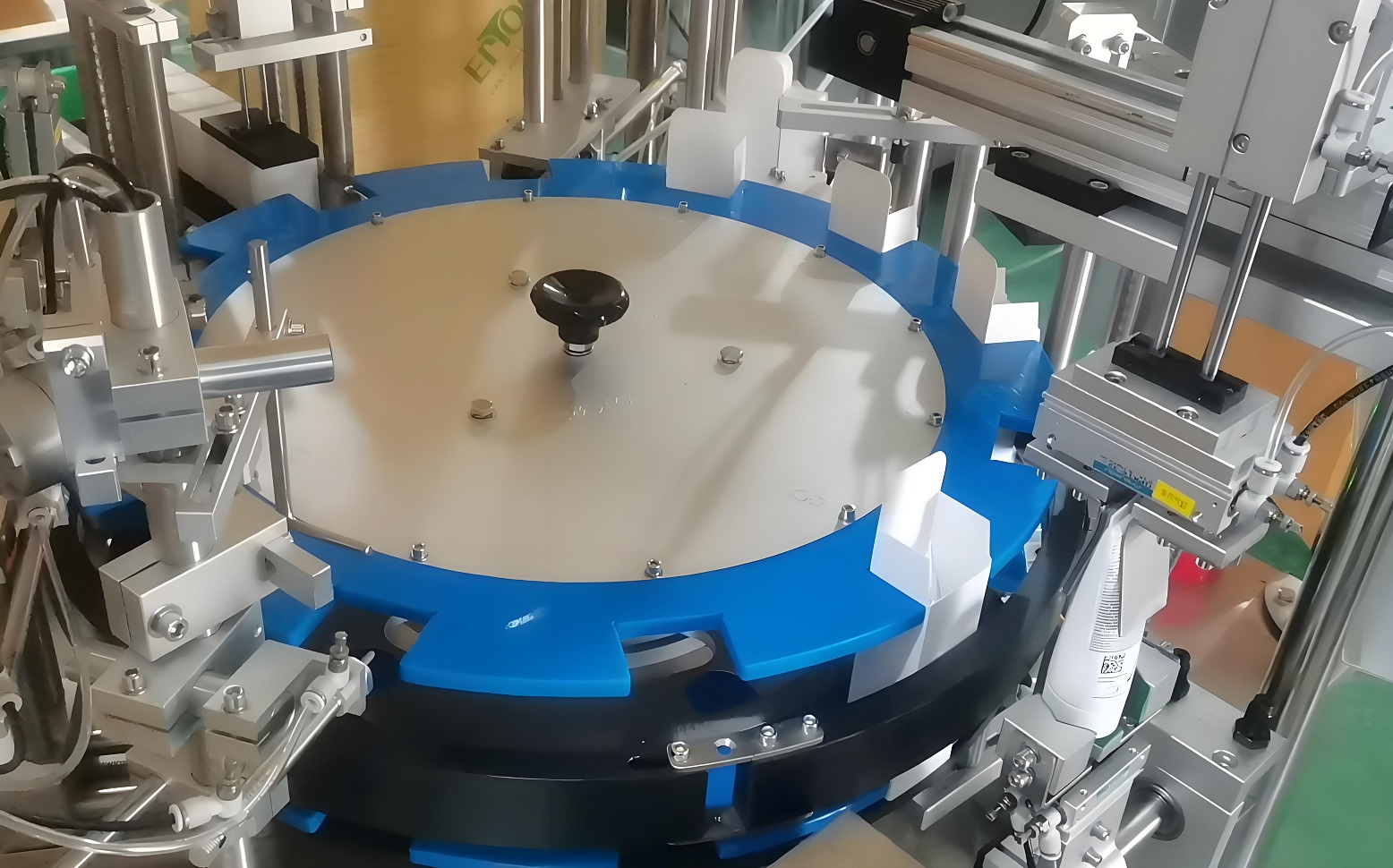

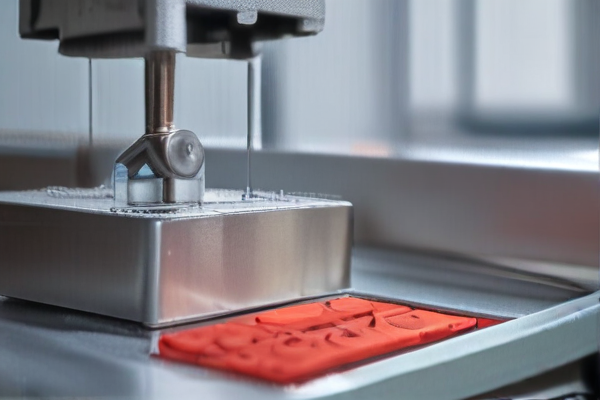

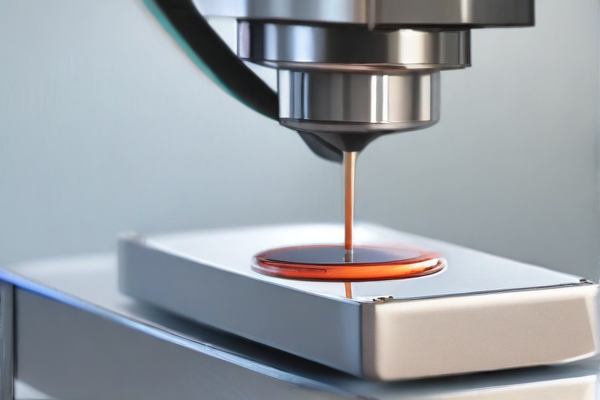

Q3: Can your induction sealing machines handle different cap sizes?

A3: Yes, our machines are designed to be versatile and can handle a wide range of cap sizes and container types with adjustable settings and interchangeable sealing heads.

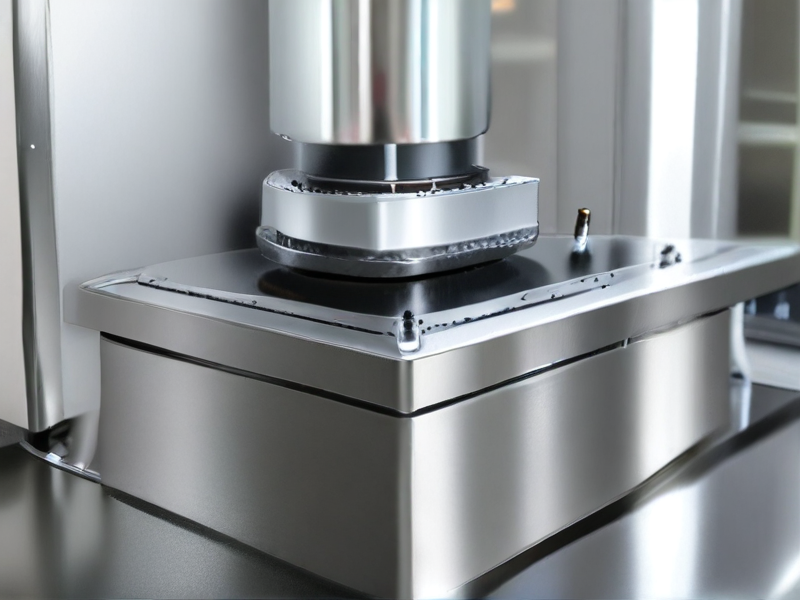

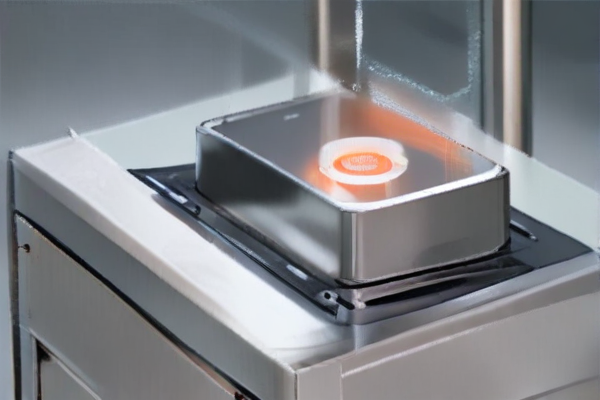

Q4: How do you ensure the quality of your induction sealing machines?

A4: We implement a rigorous quality control process that includes thorough inspection of raw materials, in-process quality checks, and comprehensive testing of the final product to ensure optimal performance.

Q5: Do you provide customization options for your machines?

A5: Yes, SourcifyChina factory offers customization options to meet specific customer requirements, including machine configuration, power settings, and specialized sealing heads.

Q6: What is the delivery time for an order?

A6: Delivery time varies depending on the order size and customization requirements. Typically, standard machines are ready for shipment within 4-6 weeks, while customized machines may take longer.

Q7: Do you offer after-sales support and maintenance services?

A7: Yes, we provide comprehensive after-sales support, including installation guidance, training, technical assistance, and maintenance services to ensure smooth and continuous operation of our machines.

Q8: What is the warranty period for your induction sealing machines?

A8: Our induction sealing machines come with a standard one-year warranty, covering any defects in materials or workmanship. Extended warranty options are also available upon request.

Q9: How can I place an order with SourcifyChina factory?

A9: You can place an order by contacting our sales team through our website, email, or phone. We will assist you in selecting the right machine and processing your order efficiently.

Q10: Can I request a sample or a demonstration of the machine before purchasing?