Sure, here are some Frequently Asked Questions (FAQ) along with their answers, specifically tailored for sourcing a jar filler machine from SourcifyChina factory.

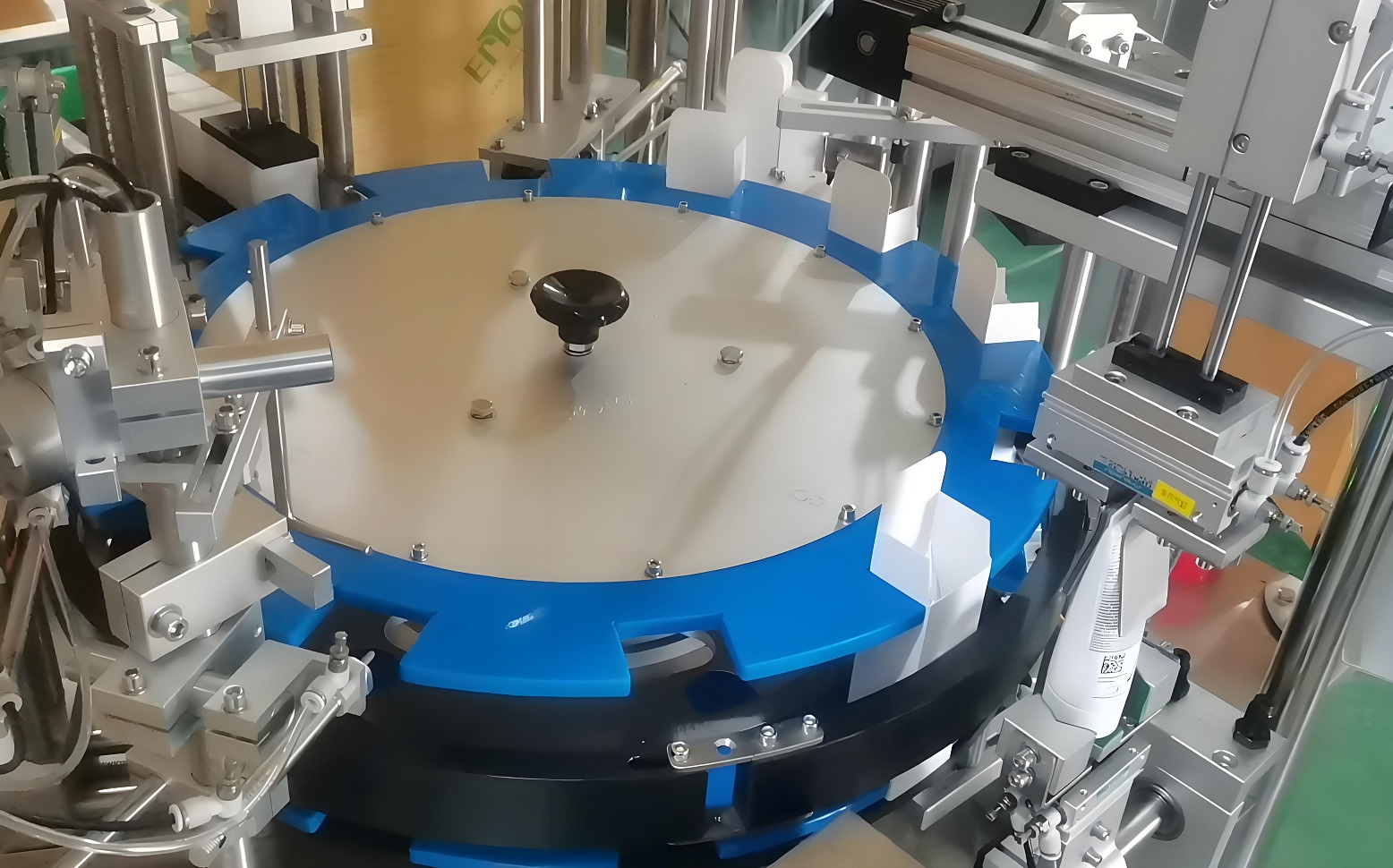

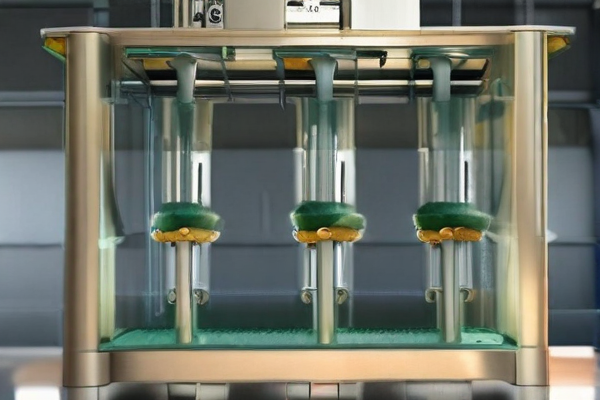

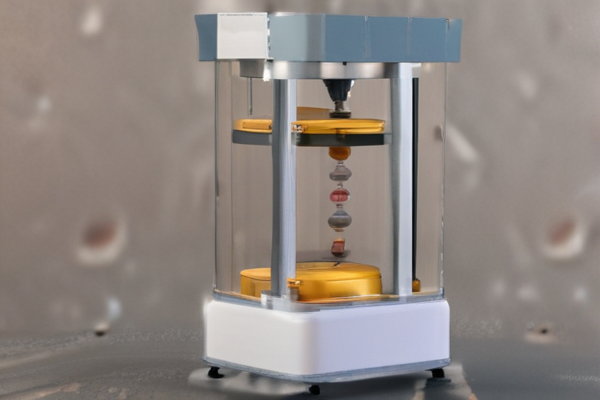

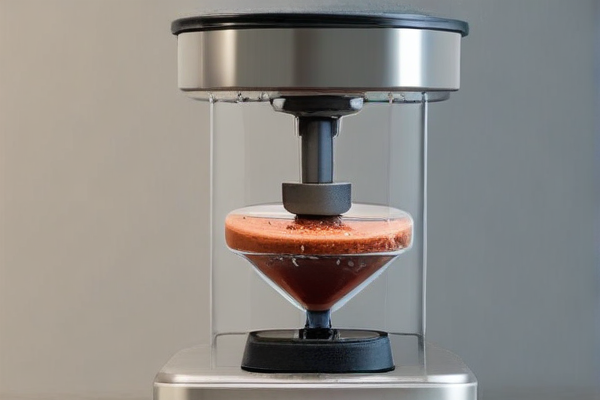

Q1: What types of jar filler machines do you offer?

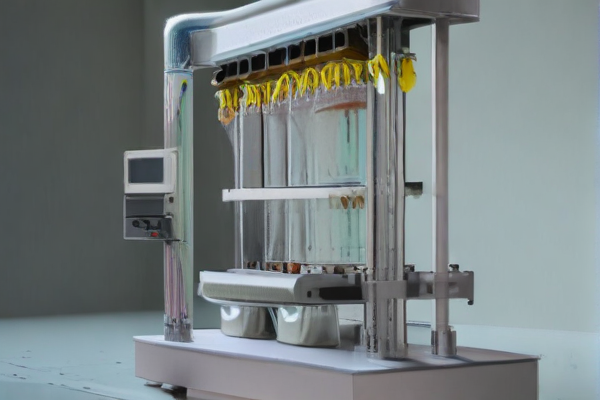

A1: SourcifyChina factory offers a variety of jar filler machines, including semi-automatic and fully automatic models, designed for different product viscosities and production volumes.

Q2: What are the minimum order requirements?

A2: The minimum order quantity can vary depending on the model and specifications. Generally, it’s one unit for standard models, but customization may require higher quantities.

Q3: Can you customize the jar filler machine to fit our specifications?

A3: Yes, SourcifyChina factory provides customization options to meet specific requirements, including size adjustments, material compatibility, and additional features.

Q4: What is the lead time for production and delivery?

A4: The typical lead time ranges from 4 to 6 weeks, depending on the complexity of the machine and order volume. Shipping times will vary based on your location.

Q5: What quality assurance processes are in place?

A5: SourcifyChina factory implements strict quality control standards, including in-house testing of each unit before shipment, to ensure the highest product quality.

Q6: What payment methods are accepted?

A6: Accepted payment methods include T/T (bank transfer), L/C (Letter of Credit), and in some cases, PayPal or credit cards for smaller orders.

Q7: Is there any warranty provided on the jar filler machines?

A7: Yes, a standard one-year warranty is provided on all jar filler machines, covering parts and labor. Extended warranties can be negotiated.

Q8: Do you offer after-sales support and maintenance services?

A8: SourcifyChina factory offers comprehensive after-sales support, including online troubleshooting, spare parts supply, and on-site maintenance services if required.

Q9: How do I place an order?

A9: Orders can be placed by contacting our sales team through email, phone, or our website. They will guide you through the process, including customization, payment, and shipment arrangements.

Q10: Can I visit the factory before placing an order?

A10: Yes, factory visits are welcomed. Arrangements can be made through our customer service team, allowing you to see the production process and quality control measures firsthand.