Q1: What types of jar filling machines does SourcifyChina factory manufacture?

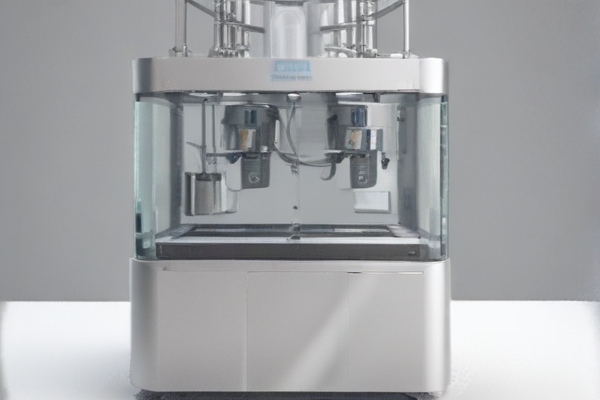

A1: SourcifyChina factory manufactures a variety of jar filling machines, including automatic, semi-automatic, and manual models. These machines are suitable for filling liquids, pastes, and powders, catering to a diverse range of industries like food, beverages, cosmetics, and chemicals.

Q2: What are the key features of SourcifyChina jar filling machines?

A2: Key features include high precision filling, user-friendly interface, adjustable filling volumes, robust construction, and easy to clean components. Additionally, many machines come with advanced automation capabilities and safety enhancements to ensure efficient and safe operations.

Q3: How does SourcifyChina ensure the quality of their jar filling machines?

A3: SourcifyChina follows strict quality control protocols, including thorough inspections at various stages of production, rigorous testing, and adherence to international manufacturing standards. They also use high-quality materials and components to ensure durability and reliability.

Q4: Can SourcifyChina design custom jar filling machines?

A4: Yes, SourcifyChina offers customization services to meet specific requirements. Their engineering team works closely with clients to design and build machines tailored to unique production needs, ensuring optimal performance and efficiency.

Q5: What is the lead time for a jar filling machine order from SourcifyChina?

A5: The lead time depends on the complexity and customization level of the order. Generally, standard models have shorter lead times, whereas custom machines may take longer. SourcifyChina provides an estimated delivery timeline during the quotation process.

Q6: Does SourcifyChina offer after-sales support and maintenance services?

A6: Yes, SourcifyChina provides comprehensive after-sales support, including installation, training, troubleshooting, and maintenance services. They ensure that customers can effectively operate and maintain their jar filling machines for long-term performance.

Q7: What is the warranty period for SourcifyChina jar filling machines?

A7: SourcifyChina offers a standard warranty period of one year for their jar filling machines, covering parts and labor. Extended warranty options may be available upon request.

Q8: How can I place an order for a jar filling machine from SourcifyChina?

A8: To place an order, contact SourcifyChina through their official website or customer service channels. Provide details about your requirements, and their sales team will guide you through the process, from quotation to delivery.