Sure, here is a list of frequently asked questions (FAQ) with answers regarding sourcing a jar labeling machine from SourcifyChina factory:

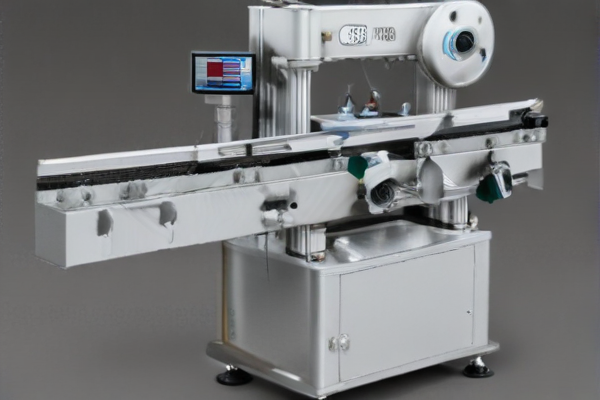

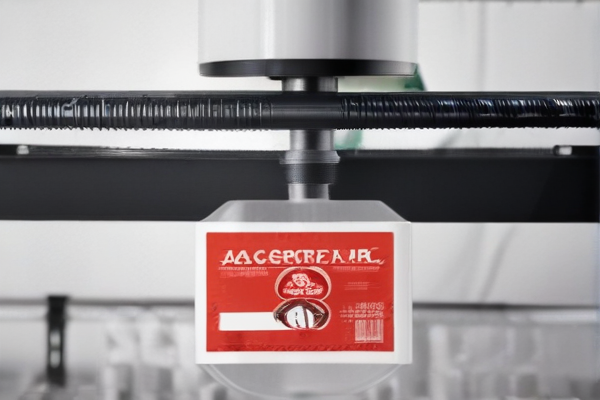

Q: What types of jar labeling machines does SourcifyChina offer?

A: SourcifyChina provides a wide range of jar labeling machines, including automatic, semi-automatic, and manual models, capable of handling different jar sizes and label types to suit various production needs.

Q: How can I get a quotation for a jar labeling machine?

A: You can obtain a quotation by visiting SourcifyChina’s official website, filling out the contact form with your requirements, or directly contacting their sales team via email or phone.

Q: What information do I need to provide for an accurate quote?

A: To get an accurate quote, provide details about your jar dimensions, type of labels (e.g., adhesive, shrink sleeves), production speed requirements, budget, and any special customization needs.

Q: Do the machines come with a warranty?

A: Yes, SourcifyChina typically offers a warranty period for their machines, covering parts and labor. Specific warranty details can be found in the product documentation or by contacting their customer service.

Q: How long does it take to deliver a jar labeling machine?

A: Delivery times vary based on the model and customization requirements but generally range from 2 to 8 weeks. For an accurate delivery timeline, consult the sales team.

Q: Is installation and training included with the purchase?

A: SourcifyChina often includes installation assistance and basic training with the purchase. Additional training or on-site support may be available upon request at an extra charge.

Q: Do you provide after-sales support and spare parts?

A: Yes, SourcifyChina offers comprehensive after-sales support, including technical assistance and spare parts supply to ensure smooth and continuous operation of your jar labeling machine.

Q: Can SourcifyChina customize the jar labeling machine to suit my specific needs?

A: Absolutely, SourcifyChina specializes in customizing machines according to client specifications. Communicate your specific needs to the sales team to get a tailor-made solution.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods, including wire transfers (T/T), letters of credit (L/C), and sometimes PayPal for initial deposits.

Q: Are there any MOQ (Minimum Order Quantities) requirements?