Q: What types of label making machines does SourcifyChina factory offer?

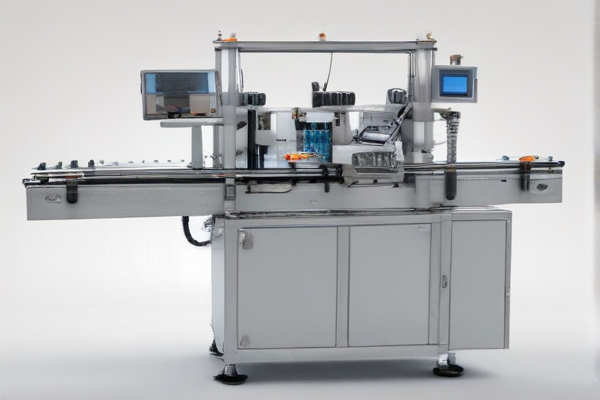

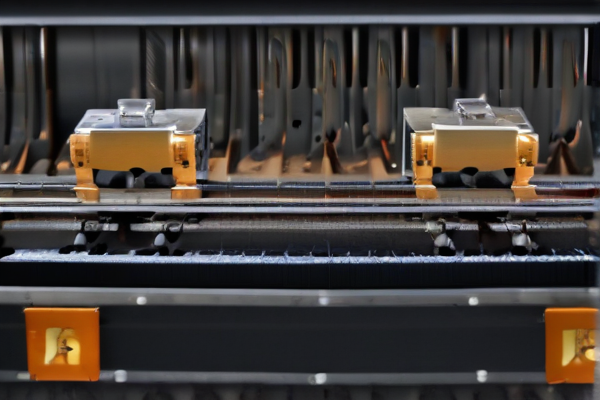

A: SourcifyChina factory offers various types of label making machines, including thermal transfer label printers, direct thermal label printers, automatic label dispensers, and multi-functional label printers for industrial and commercial use.

Q: Are the machines customizable to suit our business needs?

A: Yes, SourcifyChina factory provides customizable solutions to cater to specific business requirements, including machine size, speed, printing capacity, and additional functionalities.

Q: What are the minimum order quantities (MOQ) for label making machines?

A: The minimum order quantity varies depending on the model and type of machine. Generally, the MOQ could range from a single unit to multiple units. It’s best to inquire directly for specific details.

Q: How long does it take to manufacture and deliver a label making machine?

A: Manufacturing lead time depends on the complexity of the customizations and order volume. Typically, production takes 4-6 weeks, with an additional 1-2 weeks for shipping. Express options may be available upon request.

Q: Does SourcifyChina factory offer technical support and training?

A: Yes, SourcifyChina factory provides comprehensive technical support and training, including user manuals, online tutorials, and one-on-one training sessions to ensure smooth operation and maintenance.

Q: What is the warranty period for the label making machines?

A: SourcifyChina factory offers a standard 1-year warranty on all label making machines, covering parts and labor. Extended warranty options are also available.

Q: Can we request a sample machine for testing before placing a bulk order?

A: Yes, sample machines are available for testing. The cost can often be deducted from the bulk order price if you proceed with a larger purchase.

Q: What payment terms does SourcifyChina factory accept?

A: The factory typically accepts various payment methods, including T/T (bank transfer), L/C (letter of credit), and other negotiated terms. A deposit may be required to commence production.

Q: Are there any additional costs involved?

A: Additional costs may include shipping fees, taxes, and any custom duties applicable. It’s advisable to request a detailed quotation to understand all potential expenses.

Q: How can I place an order with SourcifyChina factory?

A: Orders can be placed directly through the factory’s sales representatives via email or phone.