Labeling machines for bottles come in various types, including automatic, semi-automatic, and manual options, each designed to suit different production needs and scales. Key factors include speed, precision, and compatibility with different bottle shapes and sizes.

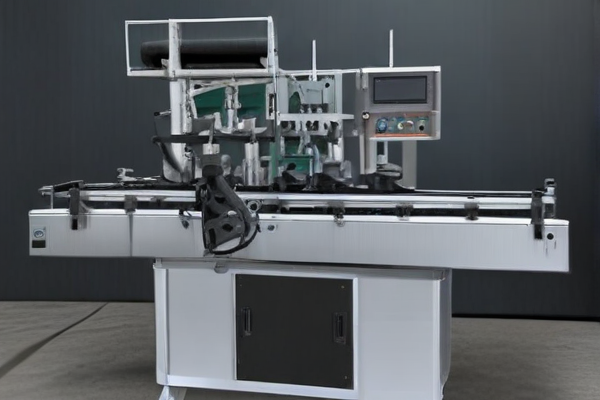

– Automatic Labeling Machines

– High-speed labeling

– Suitable for large-scale production

– Advanced features such as sensors and automated adjustments

– Semi-Automatic Labeling Machines

– Moderate production speed

– Requires manual placement of bottles

– Cost-effective for small to medium-scale operations

– Manual Labeling Machines

– Low-speed labeling

– Ideal for small businesses

– Requires full manual operation

– Pressure-Sensitive Labeling Machines

– Uses adhesive-backed labels

– Suitable for a variety of bottle materials

– Easy label changeover

– Shrink Sleeve Labeling Machines

– Uses heat to shrink labels around bottles

– Ideal for 360-degree labeling

– Compatible with different container shapes

– Hot Melt Labeling Machines

– Applies labels using hot-melt adhesive

– Fast drying and strong adhesion

– Suitable for high-speed operations

– Wet Glue Labeling Machines

– Uses liquid glue to apply paper labels

– Ideal for glass bottles

– Traditional labeling method

– Wrap-Around Labeling Machines

– Wraps labels around the entire bottle

– Suitable for cylindrical bottles

– Can be used with different label types

– Front and Back Labeling Machines

– Applies labels to both the front and back of bottles

– Ideal for containers that require multiple labels

– Ensures precise label placement

Selecting the right labeling machine depends on factors like production volume, bottle type, and label material. Each machine offers unique advantages tailored to specific needs and industry requirements.