Sure! Here are some frequently asked questions (FAQ) about manufacturing liquid filling machines with quality work from SourcifyChina factory:

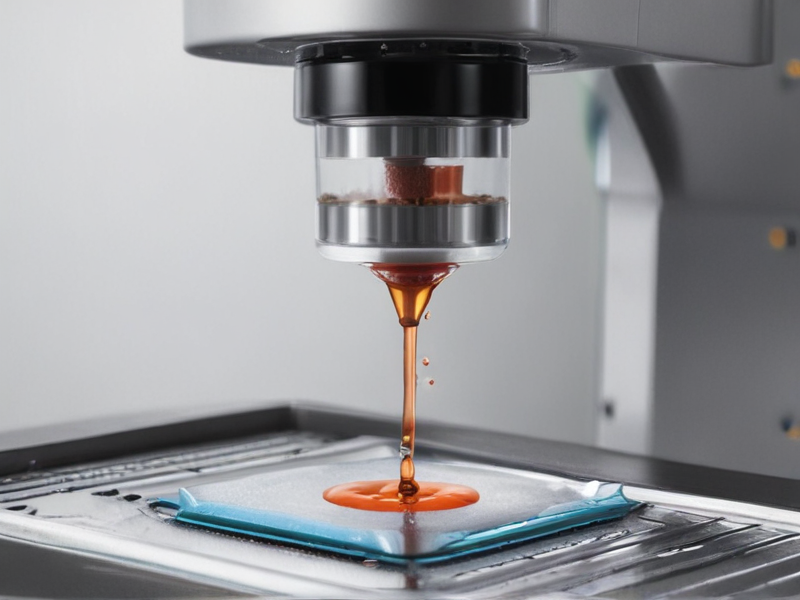

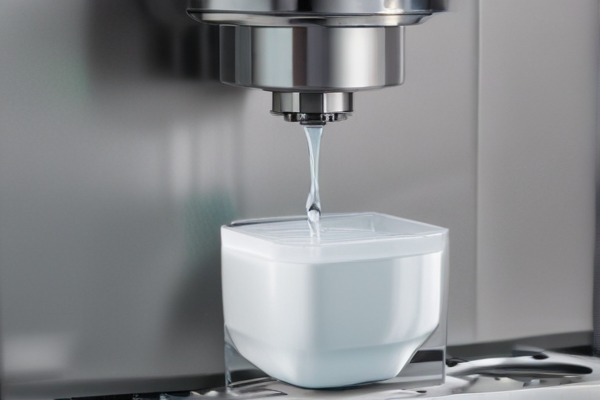

What types of liquids can SourcifyChina filling machines handle?

SourcifyChina filling machines are versatile and can handle a wide variety of liquids, including water, juice, oil, chemicals, pharmaceuticals, and more.

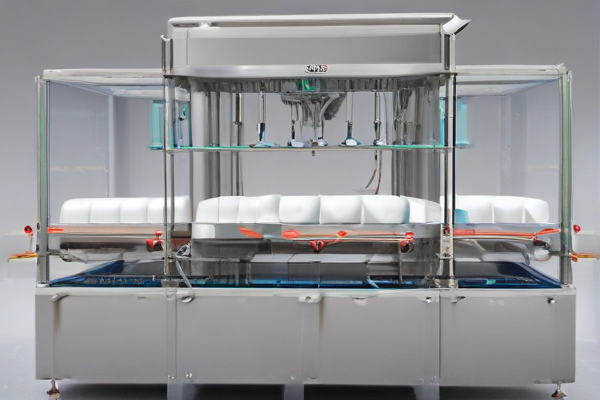

Can SourcifyChina customize liquid filling machines to specific requirements?

Yes, SourcifyChina offers customization to meet specific needs such as different filling volumes, bottle types, and production speeds.

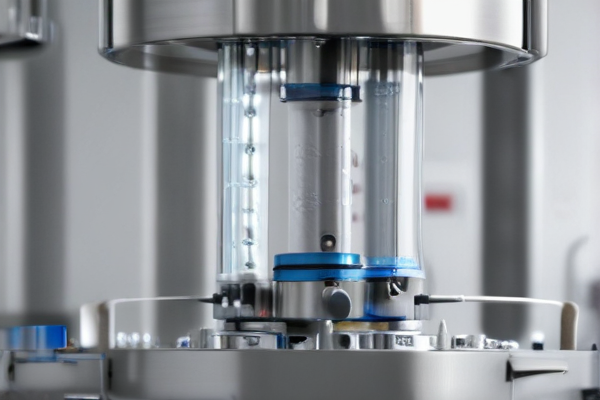

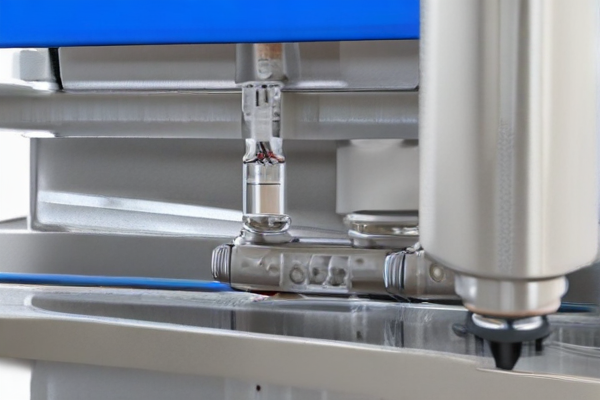

What materials are used in SourcifyChina filling machines?

Our filling machines are made from high-quality, food-grade stainless steel, ensuring durability and compliance with health standards.

Are SourcifyChina filling machines user-friendly?

Yes, our machines are designed for ease of use with intuitive interfaces and minimal training requirements, reducing the learning curve for operators.

What is the production capacity of SourcifyChina filling machines?

Production capacity varies depending on the model, but we offer machines that can handle small-scale to large-scale production, accommodating various industry needs.

Do SourcifyChina filling machines comply with international standards?

Absolutely, our machines meet international standards such as CE and ISO certifications, ensuring high quality and safety.

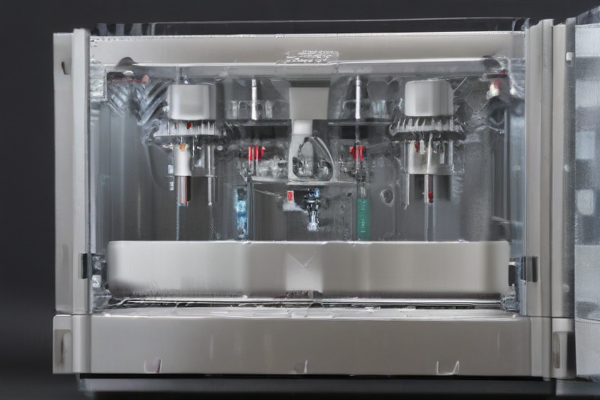

How do you ensure the quality of the liquid filling machines?

We have a rigorous quality control process that includes multiple checks and balances at each stage of production to ensure the highest quality.

What kind of maintenance is required for SourcifyChina filling machines?

Regular maintenance includes cleaning, lubrication, and periodic inspections. We provide detailed maintenance guides to facilitate this process.

What after-sales support does SourcifyChina offer?

We offer comprehensive after-sales support, including installation assistance, user training, and a reliable warranty service to address any issues.

How long does it take to manufacture and deliver a liquid filling machine from SourcifyChina?

Lead times vary based on customization and order volume, but typically it takes 4-6 weeks for manufacturing and delivery.

Can we visit the SourcifyChina factory for an inspection?

Yes, we welcome factory visits for inspections and discussions. Please contact us to schedule an appointment.

These FAQs should cover most of the common inquiries about liquid filling machine manufacturing at SourcifyChina.