Sure, here is a list of frequently asked questions (FAQ) along with concise answers related to manufacturing machine packaging quality work from SourcifyChina factory:

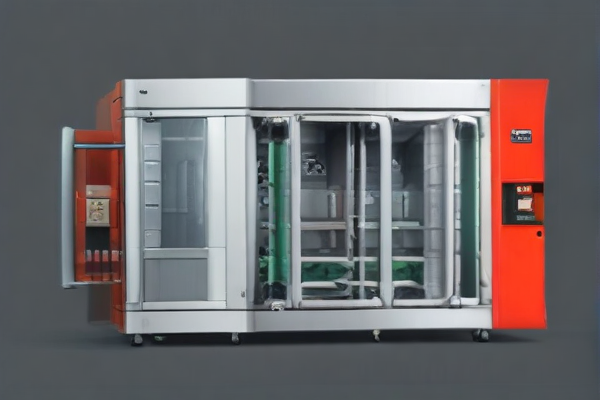

Q: What types of machinery packaging can SourcifyChina handle?

A: SourcifyChina specializes in a wide range of packaging solutions, including custom corrugated boxes, wooden crates, metal pallets, and protective packaging materials to suit various machinery sizes and shapes.

Q: How does SourcifyChina ensure the quality of the packaging materials used?

A: SourcifyChina sources high-grade raw materials and conducts stringent quality control checks throughout the production process to ensure durability and protection of the machinery during transit.

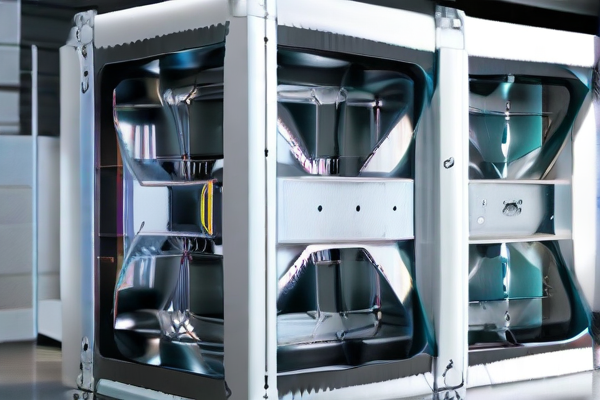

Q: Can SourcifyChina create custom packaging solutions for unique machinery?

A: Yes, SourcifyChina offers custom packaging solutions tailored to your specific machinery requirements, ensuring optimal protection and efficient shipping.

Q: What quality standards does SourcifyChina adhere to?

A: SourcifyChina complies with international quality standards such as ISO 9001 and ISTA testing protocols, ensuring that all packaging meets high-quality benchmarks.

Q: Does SourcifyChina provide sustainable packaging options?

A: Yes, SourcifyChina is committed to sustainability and offers eco-friendly packaging options made from recyclable and biodegradable materials.

Q: How does SourcifyChina handle large or heavy machinery packaging?

A: SourcifyChina designs robust packaging solutions for heavy machinery, such as reinforced wooden crates and metal frames, ensuring safe transportation and handling.

Q: What is the lead time for packaging orders at SourcifyChina?

A: Lead times vary based on the complexity and volume of the order, but SourcifyChina typically delivers packaging solutions within 2-4 weeks.

Q: Can I request a sample of the packaging before placing a bulk order?

A: Yes, SourcifyChina provides samples for approval to ensure the packaging meets your standards before proceeding with mass production.

Q: How does SourcifyChina handle international shipping of packaged machinery?

A: SourcifyChina partners with reliable logistics companies to manage international shipping, ensuring timely and secure delivery of packaged machinery.

Q: What is the process for placing an order with SourcifyChina?

A: To place an order, contact SourcifyChina’s sales team with your requirements. They will provide a quote and guide you through the design, sampling, and production stages.