Sure, here’s a concise FAQ for sourcing machines for packaging from SourcifyChina factory.

—

Q: What types of packaging machines does SourcifyChina factory offer?

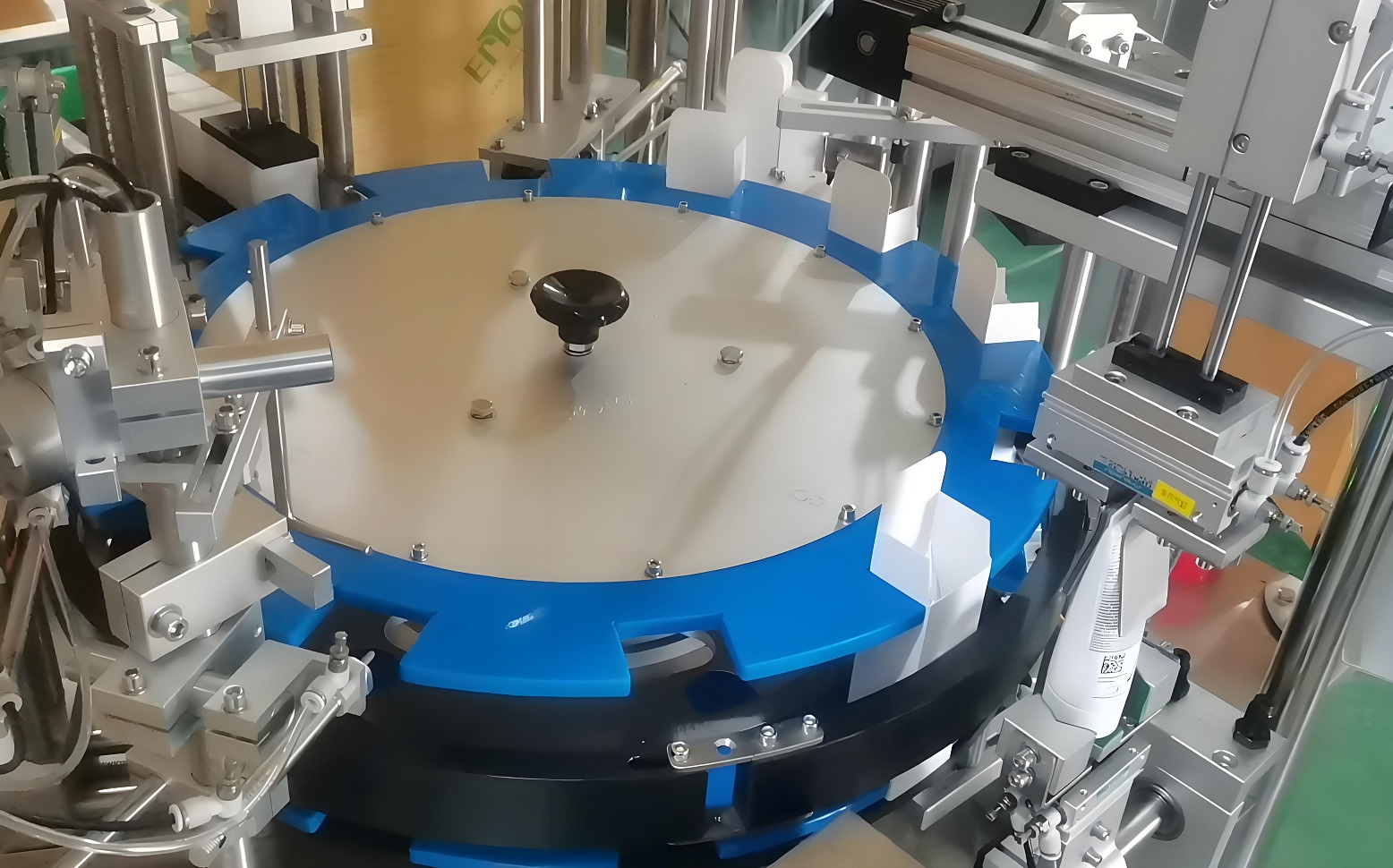

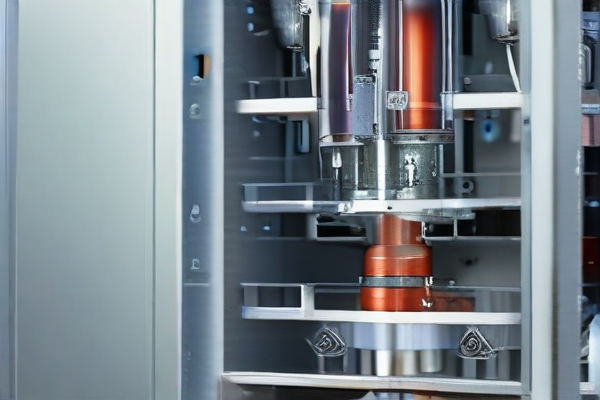

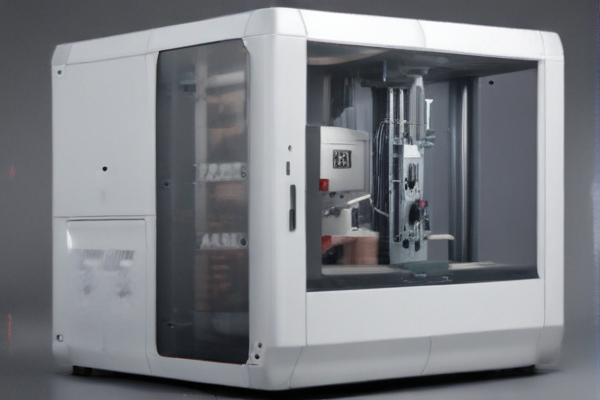

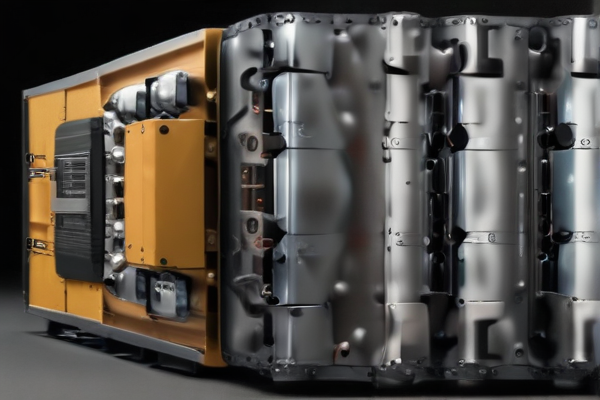

A: SourcifyChina factory provides a diverse range of packaging machines, including but not limited to, filling machines, sealing machines, wrapping machines, labeling machines, and palletizing systems. They cater to industries such as food and beverage, pharmaceuticals, cosmetics, and more.

Q: How can I ensure the quality of the packaging machines from SourcifyChina factory?

A: SourcifyChina factory adheres to strict quality control processes. They offer factory inspections, third-party certifications, and provide detailed product specifications and testing reports. Additionally, customer reviews and testimonials can offer extra peace of mind.

Q: What is the typical lead time for machine delivery?

A: The lead time for machine delivery varies depending on the machine complexity and customization requirements. Typically, it ranges between 4 to 12 weeks. SourcifyChina factory provides a detailed timeline upon order confirmation.

Q: Are there customization options available for packaging machines?

A: Yes, SourcifyChina factory offers customization to meet specific production needs. This includes adjustments in machine size, capacity, and integration with existing production lines. Consultation with their engineering team will detail the extent of customization possible.

Q: What kind of after-sales support does SourcifyChina factory offer?

A: They provide comprehensive after-sales support, including installation assistance, regular maintenance, spare parts supply, and technical support via email, phone, or on-site service, ensuring the machines operate efficiently throughout their lifecycle.

Q: How do I place an order with SourcifyChina factory?

A: Orders can be placed directly through their website or by contacting their sales team via email or phone. Specific order details, including machine type, customization requests, and delivery schedules, will be coordinated during initial consultations.

Q: What payment methods are accepted?

A: SourcifyChina factory accepts various payment methods, including bank transfers, letters of credit, and sometimes, depending on the order size and agreement, incremental payments based on milestones.

Q: Can I visit the SourcifyChina factory to inspect the machines?

A: Yes, factory visits can be arranged upon request. It’s recommended to schedule visits in advance to ensure availability and to be able to conduct a thorough inspection of the equipment and manufacturing facilities.

—