Sure, here’s a concise FAQ for the topic “Manufacturers of Packaging Machinery Quality Work from SourcifyChina Factory”:

1. What type of packaging machinery does SourcifyChina manufacture?

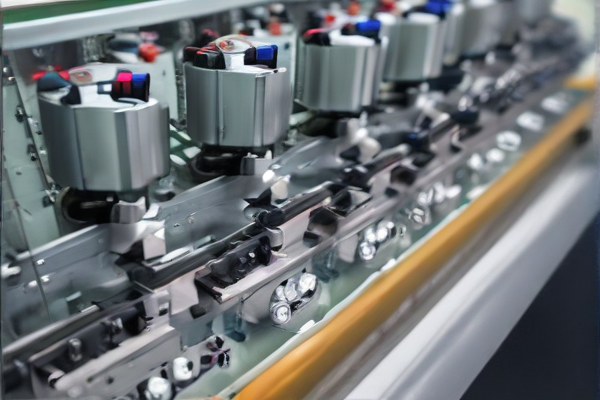

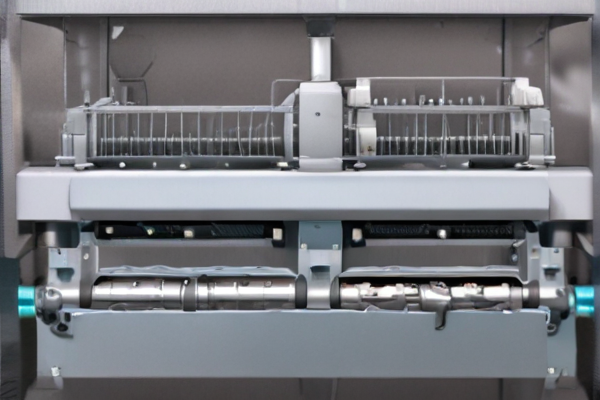

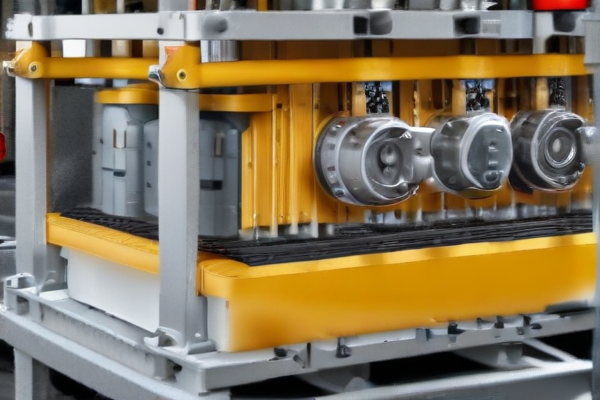

SourcifyChina manufactures a wide range of packaging machinery, including but not limited to, filling machines, capping machines, labeling machines, wrapping machines, and sealing machines, suitable for various industries such as food, pharmaceuticals, and cosmetics.

2. How does SourcifyChina ensure the quality of their packaging machinery?

SourcifyChina ensures quality through stringent quality control processes, adherence to international manufacturing standards, regular inspections, and rigorous testing of machinery components and final products.

3. Can I customize packaging machinery according to my specific needs?

Yes, SourcifyChina offers customized solutions tailored to meet your specific packaging requirements. They work closely with clients to design and manufacture machinery that meets unique specifications and production goals.

4. What is the typical lead time for manufacturing and delivery?

The lead time varies depending on the complexity and customization of the machinery, but generally, it ranges from 6 to 12 weeks. SourcifyChina continuously strives to meet deadlines and communicates transparently about production timelines.

5. Does SourcifyChina provide after-sales service and support?

Yes, SourcifyChina provides comprehensive after-sales service including installation support, operator training, maintenance services, and readily available spare parts to ensure smooth operations and minimal downtime.

6. What kind of warranty does SourcifyChina offer on their packaging machinery?

SourcifyChina offers a standard one-year warranty on all their packaging machinery, covering any manufacturing defects and ensuring free repair or replacement of faulty components within this period.

7. How does SourcifyChina maintain competitive pricing while ensuring quality?

SourcifyChina leverages efficient manufacturing processes, economies of scale, and strategic sourcing of raw materials to maintain competitive pricing without compromising on quality.

8. Can I visit the SourcifyChina factory to inspect the manufacturing process?

Yes, SourcifyChina welcomes clients to visit their factory. They can arrange guided tours to showcase their manufacturing process, quality control measures, and discuss specific project requirements.

9. How do I get a quote for my packaging machinery needs?

You can get a quote by providing detailed requirements via SourcifyChina’s website contact form or by reaching out to their sales team directly through email or phone. They will provide a comprehensive quote after assessing your needs.

10.