Sure, here are some frequently asked questions (FAQ) complete with answers for manufacturing mask machines with quality assurance from SourcifyChina factory:

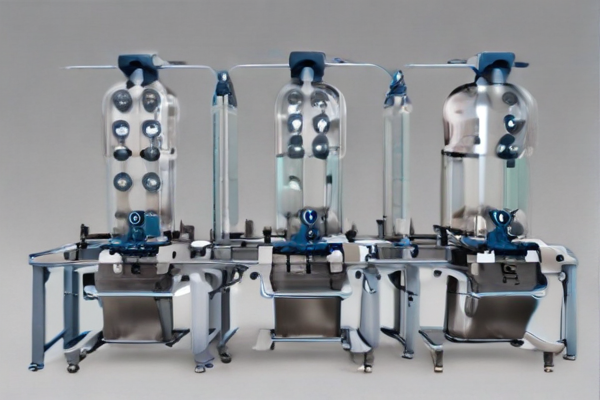

1. What types of mask machines do you manufacture?

We manufacture a range of mask machines, including disposable surgical mask machines, N95 mask machines, and full-automatic face mask machines to meet various production needs and standards.

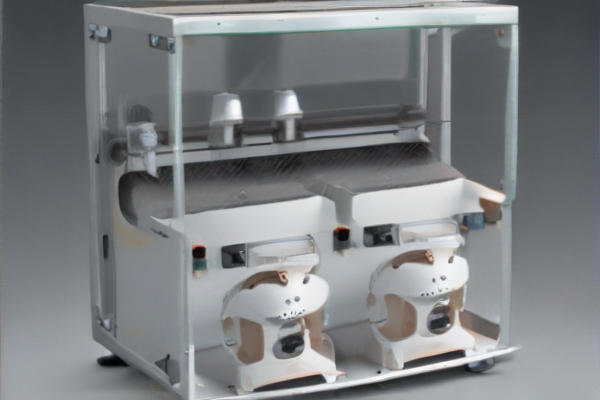

2. What is the production capacity of your mask machines?

Our machines are designed for high efficiency, with production capacities ranging from 50 to 200 masks per minute depending on the model and mask type.

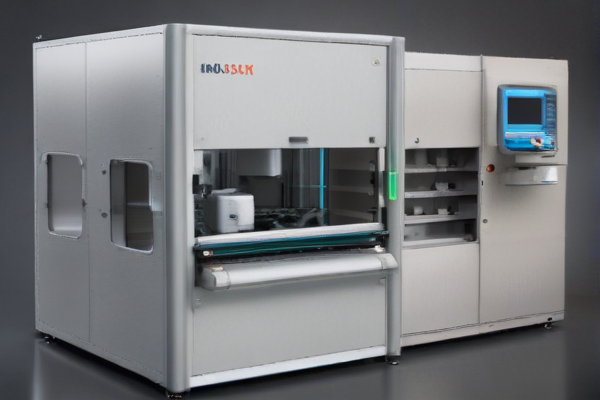

3. How do you ensure the quality of your mask machines?

We adhere to stringent quality control measures, including ISO 9001 certification, multi-stage testing, and meticulous inspection of components. Each machine undergoes rigorous testing before shipment.

4. Can your machines produce masks compliant with international standards?

Yes, our machines are capable of producing masks that comply with global standards such as FDA, CE, and GB2626-2006, ensuring high quality and safety levels.

5. How long does it take to deliver a mask machine from your factory?

The delivery timeline typically ranges from 15 to 30 days after the order is confirmed, depending on the model and customization requirements.

6. Do you offer customization for mask machines?

Yes, we provide customization services to meet specific client requirements, including machine design, production capacity, and additional features.

7. What kind of after-sales support do you provide?

We offer comprehensive after-sales support, including machine installation, operator training, maintenance services, and online technical support.

8. How do you handle warranty and repair services?

Our mask machines come with a one-year warranty for major components. We provide spare parts and repair services at minimal costs and can dispatch engineers to your location if necessary.

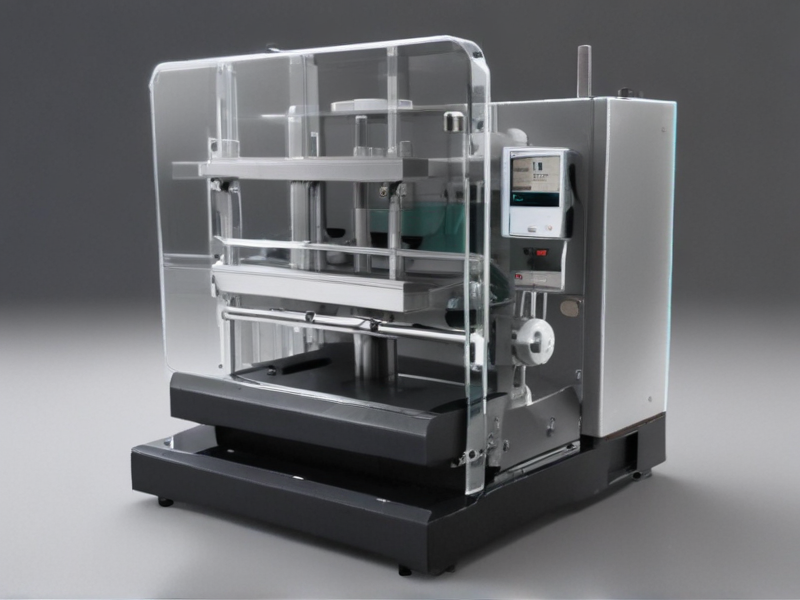

9. Are your machines user-friendly?

Absolutely. Our machines are designed for ease of use with intuitive interfaces and comprehensive user manuals, making them accessible for operators with varying levels of experience.

10. How do I place an order and what payment methods do you accept?

To place an order, please contact our sales team via phone or email. We accept various payment methods, including wire transfer, PayPal, and credit card payments.