Sure, here is a list of frequently asked questions (FAQ) about the quality of meat wrapping machines manufactured by SourcifyChina Factory:

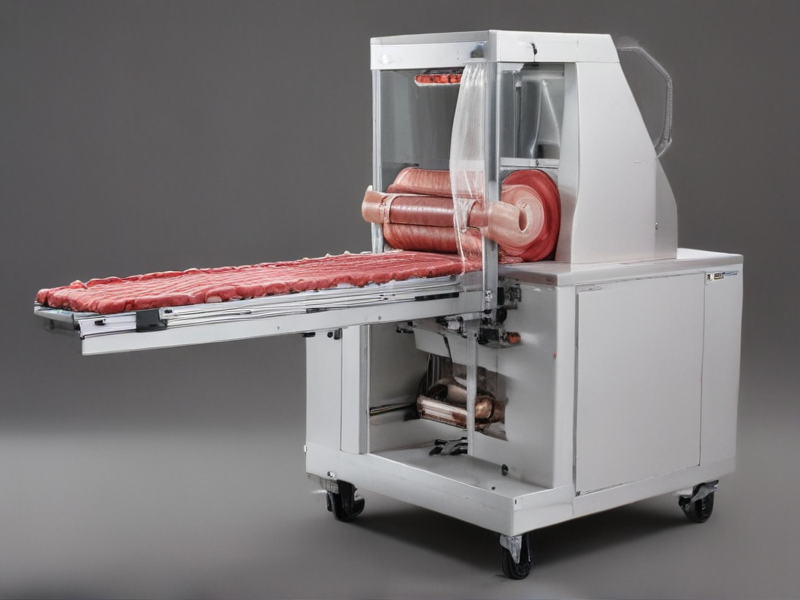

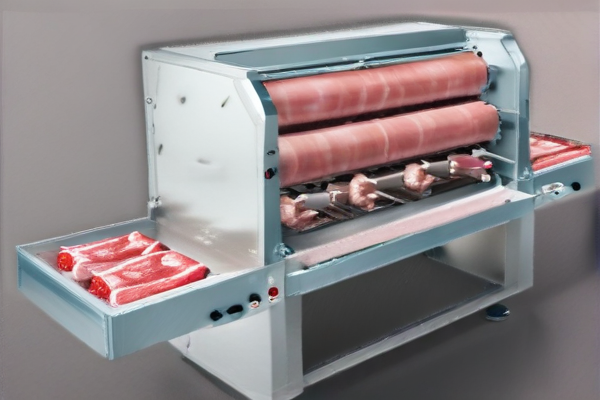

1. What types of meat wrapping machines does SourcifyChina manufacture?

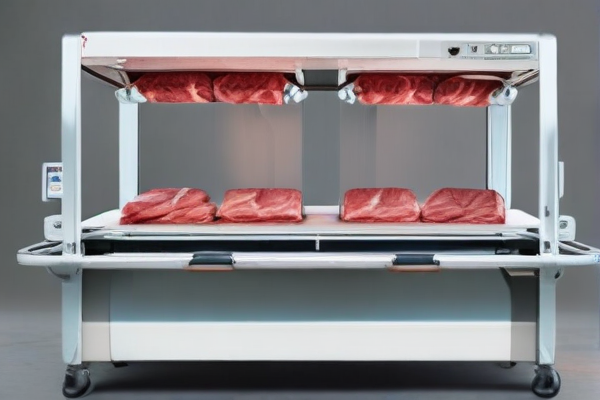

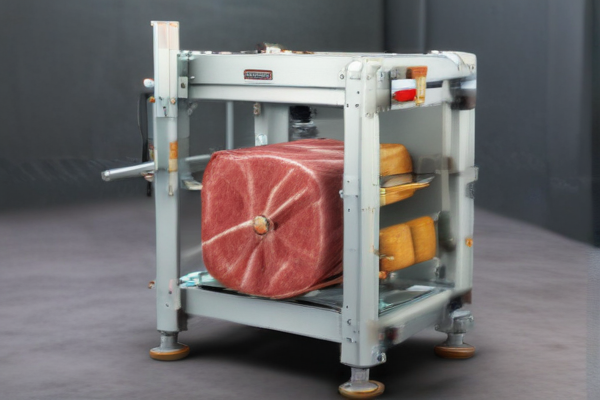

SourcifyChina manufactures a variety of meat wrapping machines, including automatic, semi-automatic, and manual models. They cater to different packaging needs and capacities, ensuring that all clients’ requirements are met.

2. Are SourcifyChina’s meat wrapping machines compliant with international quality standards?

Yes, SourcifyChina ensures that their meat wrapping machines comply with international quality standards such as ISO, CE, and FDA where applicable. They undergo rigorous testing to meet industry benchmarks.

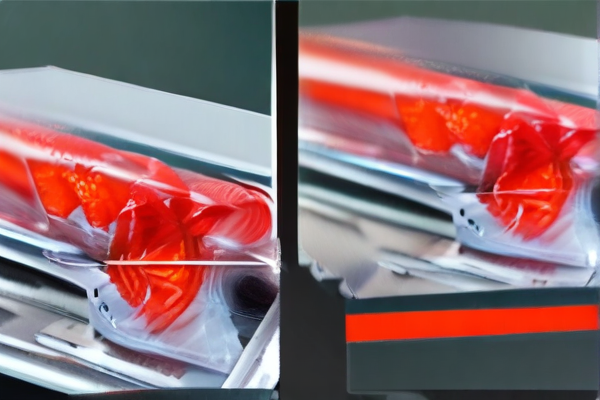

3. What materials are used in the construction of these machines?

SourcifyChina uses high-grade stainless steel and food-safe materials to construct their meat wrapping machines. This ensures durability, hygiene, and compliance with food safety regulations.

4. How do I know if the machine is suitable for my production needs?

SourcifyChina offers consultations where they assess your production requirements and recommend the most suitable machine. They also provide detailed specifications and user manuals for each model.

5. What kind of maintenance is required for these machines?

Regular maintenance includes routine cleaning, checking for wear and tear, and lubrication of moving parts. SourcifyChina provides a comprehensive maintenance guide and offers after-sales support to ensure optimum performance.

6. Can I get a customization option for specific packaging needs?

Yes, SourcifyChina offers customization options to meet specific packaging requirements. You can discuss your specific needs with their engineering team to develop a tailored solution.

7. What is the average lead time for delivery?

The average lead time for delivery varies depending on the model and customization requirements, typically ranging from 4 to 8 weeks.

8. Does SourcifyChina provide training for operating the machines?

Yes, they provide comprehensive training for your staff to ensure that the machines are operated efficiently and safely. Training materials and on-site training sessions are available upon request.

9. What is the warranty period for the meat wrapping machines?

SourcifyChina offers a standard one-year warranty on their meat wrapping machines, covering parts and labor. Extended warranty options are also available.

10. How can I contact SourcifyChina for further inquiries?