Sure, here are some FAQs and answers for sourcing a medicine packing machine from SourcifyChina Factory:

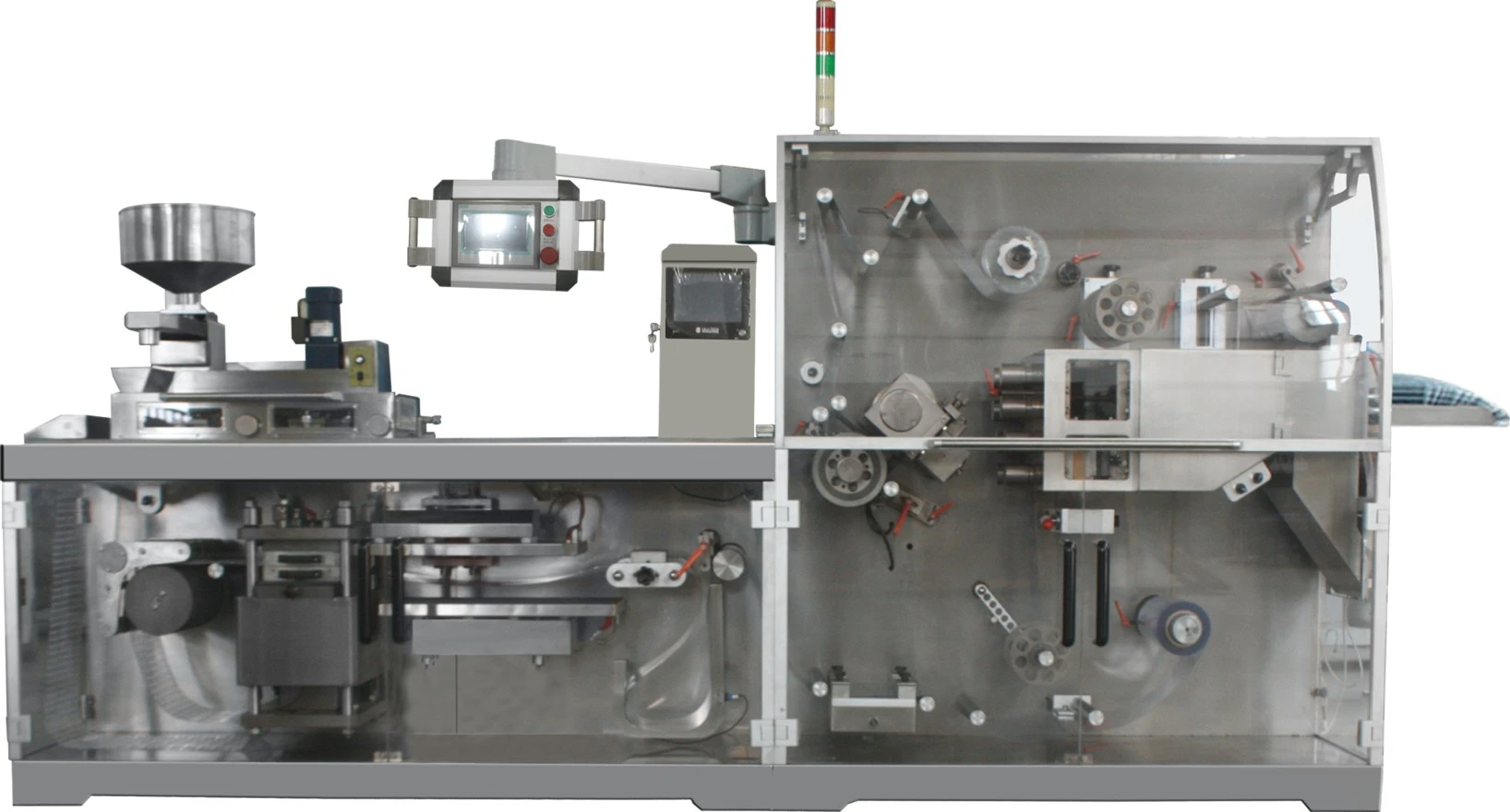

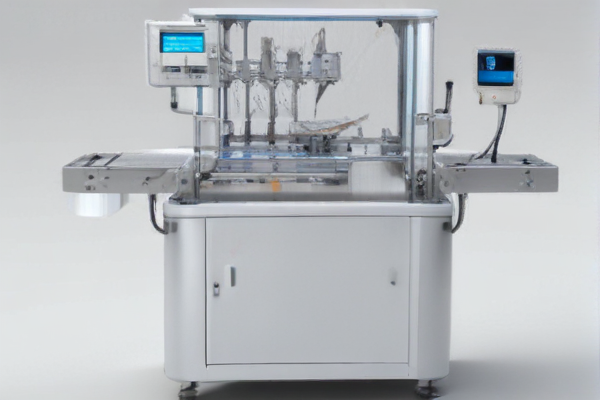

Q: What types of medicine packing machines does SourcifyChina offer?

A: SourcifyChina provides a variety of medicine packing machines, including blister packing machines, strip packing machines, sachet packing machines, and bottle packing machines, each tailored to different requirements.

Q: How can I ensure the quality of the machines?

A: SourcifyChina ensures quality by adhering to international standards and maintaining stringent quality control measures. They also offer comprehensive testing and certification processes, and you can request machine samples or visit their factory for inspections.

Q: What are the payment terms for purchasing a machine?

A: Common payment terms include 30% deposit upon order confirmation and the remaining 70% before shipment. However, SourcifyChina may offer flexible payment options based on negotiation and relationship.

Q: Are there customizations available for the packing machines?

A: Yes, SourcifyChina offers customization options to meet specific requirements such as machine dimensions, packing speed, and material compatibility. Consultation with their technical team is recommended for bespoke solutions.

Q: What is the typical lead time for delivery?

A: The lead time for delivery generally ranges from 4 to 8 weeks depending on the complexity and quantity of the order. SourcifyChina provides regular updates on the manufacturing progress and estimated delivery time.

Q: Do they provide installation and training services?

A: Yes, SourcifyChina offers comprehensive installation and training services to ensure proper machine operation. This can include on-site setup and training sessions or remote guidance if necessary.

Q: What after-sales support is available?

A: SourcifyChina provides robust after-sales support including warranty services, spare parts supply, and technical assistance. Their support team can be contacted for troubleshooting and maintenance guidance.

Q: How do I place an order?

A: Orders can be placed directly through their website or by contacting their sales team via email or phone. Provide detailed requirements to receive a tailored quotation and proceed with the purchase process.

Q: What documents are required to import the machine?

A: Necessary documentation typically includes the commercial invoice, packing list, bill of lading, and certificates of conformity. SourcifyChina assists in preparing all required documents for smooth customs clearance.

For additional information, you can visit SourcifyChina’s website or contact their customer service directly.