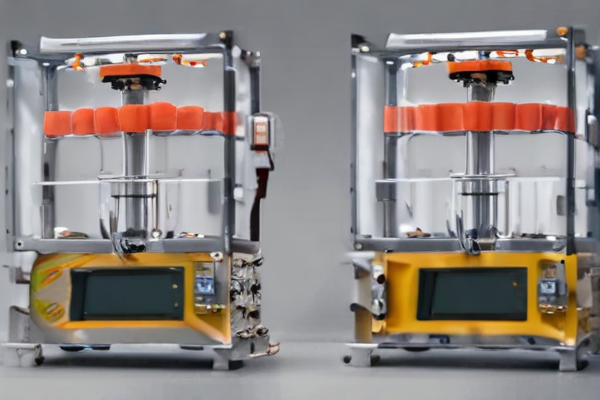

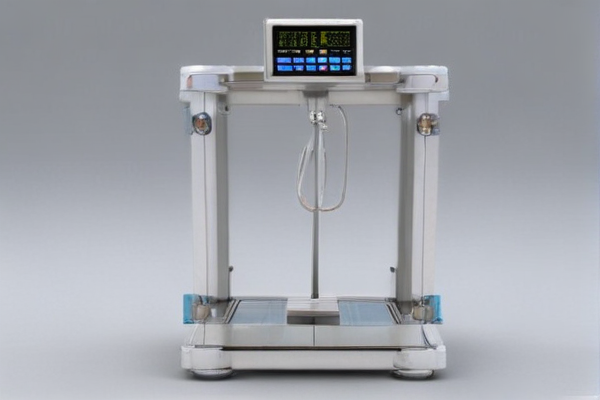

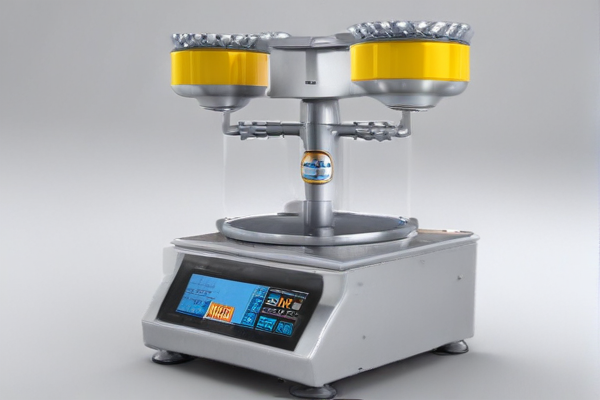

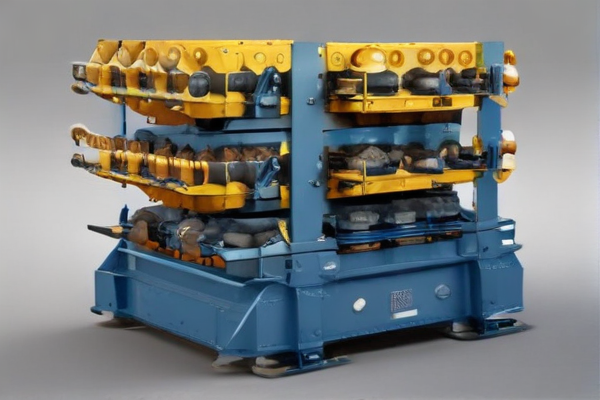

A multihead weighing machine is widely used in packaging to weigh products with high accuracy and speed. This technology is essential for ensuring consistent product quantities across various industries.

Applications of Multihead Weighing Machine:

– Food Industry: Weighing snacks, candies, frozen foods, and fresh produce.

– Pharmaceuticals: Accurate dosage measurement for medicine packaging.

– Cosmetics: Weighing powders, creams, and other semi-liquid products.

– Pet Food: Ensuring consistent portions for dry and wet pet foods.

– Hardware: Weighing screws, bolts, and other small hardware items.

– Bakery: Portion control for baked goods like cookies and bread.

– Agricultural Products: Weighing seeds, grains, and pulses.

– Chemicals: Measuring precise quantities of powdered chemicals.

– Frozen Foods: Accurate portioning of frozen vegetables and meals.

– Confectionery: Weighing chocolates, gummies, and other sweets.

– Tea and Coffee: Ensuring the right amount per package.

– Dairy Products: Weighing cheese, butter, and other dairy items.

– Snack Foods: Weighing chips, nuts, and other snack products.

– Plastic Components: Precise weighing for small plastic parts.

– Meat and Seafood: Weighing cuts and portions for packaging.

– Health and Nutrition: Accurate portion control for dietary supplements.

– Electronic Components: Weighing small electronic parts.

– Retail Packaging: Ensuring accurate and uniform packaged retail goods.

– Petroleum Products: Weighing fine powders and additives.

– Bakery Ingredients: Weighing flour, sugar, and other ingredients.

– Spices and Herbs: Precision dosing for spices and herbs.

– Automotive Parts: Weighing components for automotive assemblies.

– Luxury Goods: Weighing high-value items like jewels or specialized parts.

– Research Laboratories: Weighing compounds and samples for experiments.