Sure, here are some FAQs with answers regarding the quality of nail polish filling machines manufactured by SourcifyChina Factory:

Q: What materials are used in the construction of SourcifyChina’s nail polish filling machines?

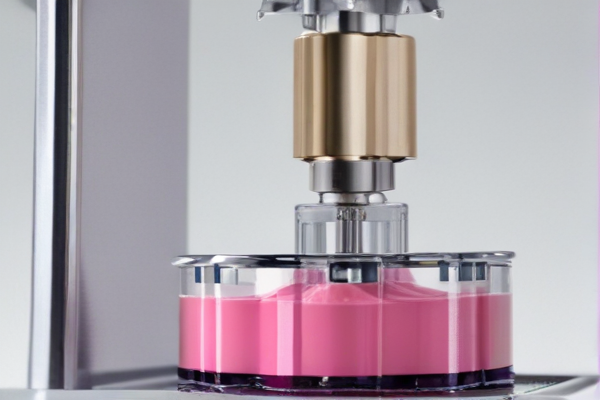

A: SourcifyChina utilizes high-grade stainless steel and food-grade silicone for parts that come into contact with the nail polish, ensuring both durability and safety.

Q: How precise are the filling capacities of these machines?

A: SourcifyChina’s nail polish filling machines can achieve an accuracy of ±0.5%, ensuring consistent fill levels and reducing product waste.

Q: Are these machines capable of handling different types of nail polish formulas?

A: Yes, SourcifyChina’s machines are designed to handle various nail polish formulations, including glitter, gel, and matte finishes, without clogging or uneven filling.

Q: What is the typical production speed for these machines?

A: The production speed can vary depending on the model, but most SourcifyChina machines can fill between 30-60 bottles per minute.

Q: Are the machines easy to clean and maintain?

A: Absolutely. The machines are designed for easy disassembly, allowing for straightforward cleaning and maintenance to ensure long-term performance.

Q: What kind of technical support does SourcifyChina offer?

A: SourcifyChina provides comprehensive technical support, including online assistance, on-site troubleshooting, and a detailed user manual for new users.

Q: Is there a warranty on the nail polish filling machines?

A: Yes, all nail polish filling machines from SourcifyChina come with a 1-year warranty, covering any manufacturing defects or performance issues.

Q: How customizable are the machines for different bottle sizes and shapes?

A: SourcifyChina offers a range of customizable options to accommodate various bottle sizes and shapes, ensuring compatibility with your unique packaging needs.

Q: What are the power requirements for these machines?

A: The machines typically operate on 220V/50Hz, but custom configurations can be made to meet different regional power requirements.

Q: How long does it take to receive an order after it’s placed?

A: Standard production and delivery time is approximately 4-6 weeks, depending on the order size and customizations requested.

These FAQs should give you a good understanding of the quality and functionality of nail polish filling machines from SourcifyChina Factory.