Sure, here are some FAQs for the manufacturing of a “nail polish filling machine” from SourcifyChina factory:

What types of nail polish filling machines do you offer?

We offer a range of nail polish filling machines including fully automatic, semi-automatic, and manual machines, designed to meet various production needs and budgets.

What is the production capacity of your nail polish filling machines?

Our machines vary in capacity, with options ranging from 20-30 bottles per minute for lower-end models to 100+ bottles per minute for high-end automatic machines.

Are your machines compatible with different bottle sizes and shapes?

Yes, our filling machines are adjustable and can accommodate a variety of bottle sizes and shapes. Customizations are available to meet specific requirements.

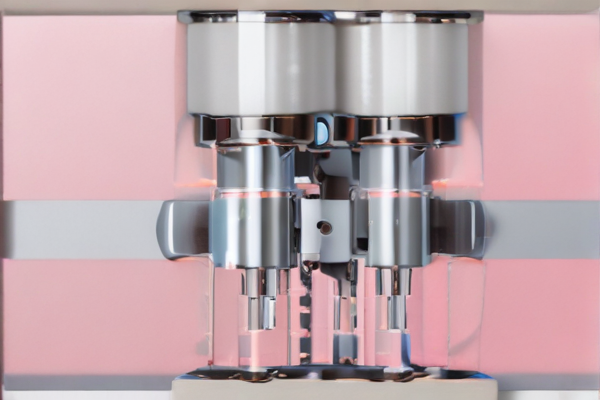

What type of filling technology is used in your machines?

Our machines typically use piston filling and peristaltic pump technologies to ensure accurate and consistent filling without spillage or contamination.

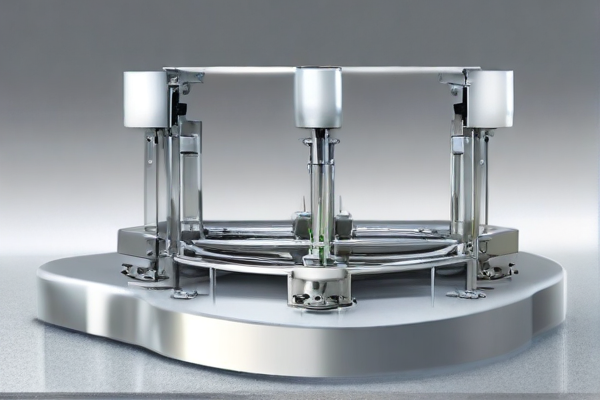

What materials are used in the construction of your machines?

Our nail polish filling machines are made from high-quality stainless steel and other durable materials to ensure longevity and resistance to corrosion.

Do you provide training and support for operating the machines?

Yes, we offer comprehensive training and support services, including manuals, video tutorials, and on-site training options to help you get started.

How do you ensure the quality of your nail polish filling machines?

We adhere to strict quality control measures, including multiple inspections and testing phases, to ensure that each machine meets the highest standards before delivery.

Are spare parts readily available for your machines?

Yes, we maintain an inventory of commonly required spare parts and can provide replacements quickly to minimize downtime.

What is the warranty period for your nail polish filling machines?

Our machines come with a standard one-year warranty, covering any manufacturing defects. Extended warranty options are also available upon request.

Can your machines be integrated into an existing production line?

Yes, our machines are designed for easy integration with existing production lines, ensuring smooth and efficient operations.

These FAQs should help provide a comprehensive overview of the nail polish filling machines offered by SourcifyChina factory.