Sure! Here are some FAQs with answers for sourcing a nasal spray filling machine from SourcifyChina factory:

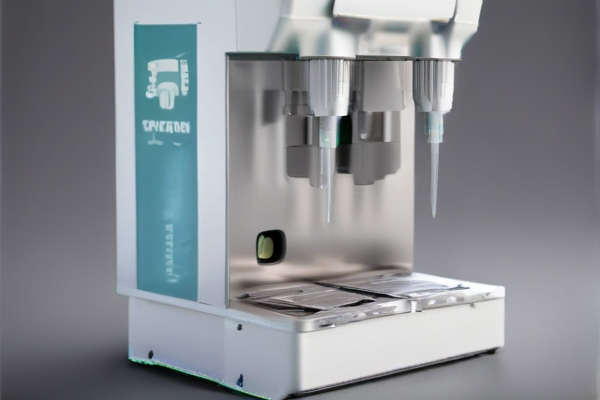

1. What types of nasal spray filling machines does SourcifyChina offer?

SourcifyChina provides a variety of nasal spray filling machines, ranging from manual to fully automated systems, designed to handle different volumes and specific needs of the pharmaceutical and healthcare industries.

2. How can I get a detailed quotation for a nasal spray filling machine?

To obtain a detailed quotation, please visit SourcifyChina’s website and fill out the inquiry form with your specific requirements. Alternatively, you can contact their sales team directly via email or phone.

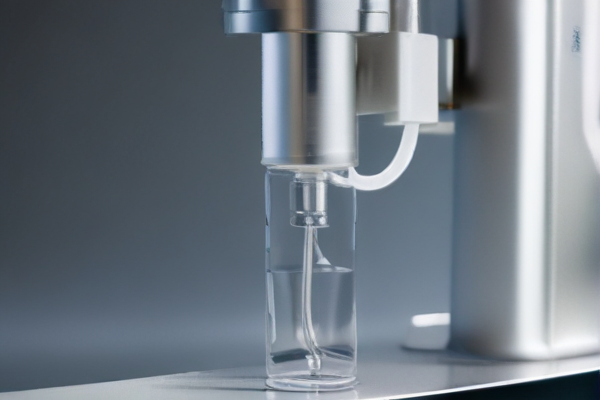

3. What materials are used in the construction of the filling machines?

The nasal spray filling machines are constructed using high-quality stainless steel to ensure durability, compliance with hygiene standards, and resistance to corrosion.

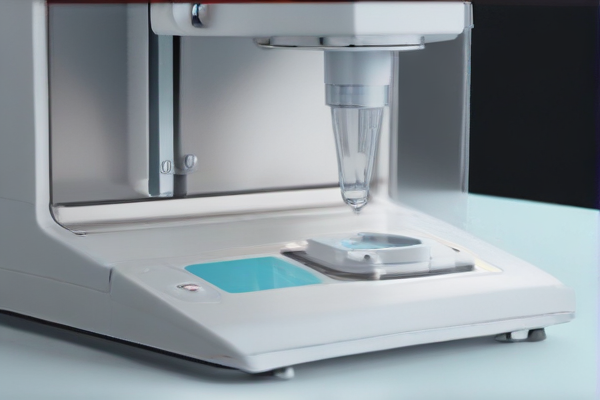

4. Are the machines compatible with different bottle sizes and types?

Yes, SourcifyChina’s machines are designed with adjustable components to accommodate various bottle sizes and types. Customization options are also available upon request.

5. Do the machines comply with international standards?

Absolutely. SourcifyChina ensures that all its nasal spray filling machines comply with international standards such as CE and GMP to meet the regulatory requirements of different countries.

6. What is the typical lead time for manufacturing and delivery?

The lead time varies depending on the machine specifications and order quantity. Typically, it ranges from 6 to 12 weeks. Detailed timelines will be provided upon order confirmation.

7. Is there any warranty and after-sales support?

Yes, SourcifyChina offers a comprehensive warranty and robust after-sales support including installation assistance, troubleshooting, and maintenance services.

8. Can I visit the factory to inspect the machines?

Yes, factory visits can be arranged. Please contact the sales team to schedule an appointment and ensure all necessary arrangements are made for your visit.

9. What payment methods does SourcifyChina accept?

SourcifyChina accepts various payment methods including wire transfer (T/T), credit card, and, often, L/C (Letter of Credit) for international transactions.

10. Are training and installation services included in the purchase?

Training and installation services can be included upon request. SourcifyChina provides skilled technicians to ensure proper installation and comprehensive training for your staff.