Sure! Here is a concise FAQ list for manufacturing an oil filling machine line with SourcifyChina factory:

1. What types of oil filling machines does SourcifyChina offer?

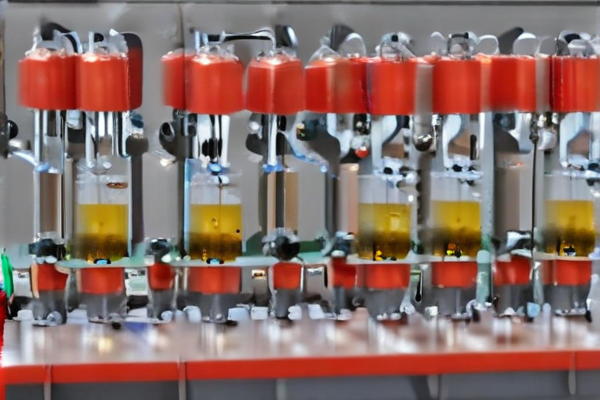

SourcifyChina provides a variety of oil filling machines, including automatic, semi-automatic, and manual models suitable for different levels of production capacity and types of oil.

2. What materials are used in the construction of these filling machines?

Our oil filling machines are constructed using high-grade stainless steel and certified food-grade materials to ensure durability, hygiene, and compliance with industry standards.

3. What is the typical lead time for production and delivery?

Usually, the lead time for production is between 4 to 8 weeks, depending on the complexity and scale of the order. Delivery times may vary based on the destination.

4. Are the machines compatible with different types of oils?

Yes, SourcifyChina’s oil filling machines can handle a wide range of oils, including edible oils (olive, sunflower, soybean), essential oils, and lubricating oils. Customization options are available to suit specific needs.

5. Can the machines be customized according to our specific requirements?

Absolutely. We offer customization services to adjust machine specifications, such as filling volume, type of bottle or container, and production capacity to meet your unique requirements.

6. What kind of after-sales support does SourcifyChina offer?

We provide comprehensive after-sales support, including installation assistance, training, maintenance services, and 24/7 customer support to ensure the smooth operation of your filling line.

7. How does SourcifyChina ensure the quality of their machines?

Quality is assured through rigorous quality control processes, including pre-production inspections, in-process monitoring, and final testing before shipment. We are ISO and CE certified, reflecting our commitment to high industry standards.

8. What is the warranty period for the oil filling machines?

SourcifyChina offers a one-year warranty on all oil filling machines, covering any manufacturing defects or malfunctioning parts with options for extended warranties.

9. How energy-efficient are these machines?

Our oil filling machines are designed to be energy-efficient, utilizing advanced technology to minimize power consumption while maximizing output.

10. What payment methods are accepted?

We accept various payment methods, including bank transfers (TT), credit cards, and letters of credit (L/C), to provide flexibility and convenience for our customers.

Hopefully, this FAQ provides a clear and succinct overview of SourcifyChina’s oil filling machine line.